Redesigning S&OP Into a Confident, Execution-Ready Planning System

Redesigning S&OP Into a Confident, Execution-Ready Planning System

Redesigning S&OP Into a Confident, Execution-Ready Planning System

About Project

About Project

About Project

Sales & Operations Planning (S&OP) is critical in pharma for balancing demand forecasts, production capacity, inventory, and regulatory constraints.

Audree’s existing S&OP process was fragmented and spreadsheet-driven, relying heavily on manual coordination across Sales, Supply Chain, Production, QA, and Leadership teams. Disconnected data, version mismatches, and limited visibility slowed planning cycles and reduced confidence in decisions.

Audree initiated a redesign to create a single, structured, and audit-ready S&OP system that enables compliant planning, cross-functional alignment, and confident decision-making.

Sales & Operations Planning (S&OP) is critical in pharma for balancing demand forecasts, production capacity, inventory, and regulatory constraints.

Audree’s existing S&OP process was fragmented and spreadsheet-driven, relying heavily on manual coordination across Sales, Supply Chain, Production, QA, and Leadership teams. Disconnected data, version mismatches, and limited visibility slowed planning cycles and reduced confidence in decisions.

Audree initiated a redesign to create a single, structured, and audit-ready S&OP system that enables compliant planning, cross-functional alignment, and confident decision-making.

About Project

Pharmaceutical

Team

Anush Reddy, S.Madhumala

Subscription Category

Quick win

Project start Year

August 2025

Core Business Challenges

Core Business Challenges

Core Business Challenges

Poor User Adoption Due to Outdated Experience

Poor User Adoption Due to Outdated Experience

Poor User Adoption Due to Outdated Experience

Complex, spreadsheet-driven screens were hard to interpret, leading to low adoption and continued reliance on offline planning.

Complex, spreadsheet-driven screens were hard to interpret, leading to low adoption and continued reliance on offline planning.

Complex, spreadsheet-driven screens were hard to interpret, leading to low adoption and continued reliance on offline planning.

Slowed by Process Inefficiency

Slowed by Process Inefficiency

Slowed by Process Inefficiency

Planning workflows were spread across spreadsheets , with frequent reconciliations and unclear handoffs slowing demand & supply planning,

Planning workflows were spread across spreadsheets , with frequent reconciliations and unclear handoffs slowing demand & supply planning,

Planning workflows were spread across spreadsheets , with frequent reconciliations and unclear handoffs slowing demand & supply planning,

Heavy Dependence on Manual Coordination

Heavy Dependence on Manual Coordination

Limited real-time visibility forced reliance on emails and calls, increasing follow-ups, delays, and operational overhead.

Limited real-time visibility forced reliance on emails and calls, increasing follow-ups, delays, and operational overhead.

Heavy Dependence on Manual Coordination

Limited real-time visibility forced reliance on emails and calls, increasing follow-ups, delays, and operational overhead.

Our Approach

Our Approach

Our Approach

Mapping User Flows to Uncover Hidden Gaps

We mapped the complete S&OP lifecycle from demand capture and procurement inputs to review, approvals, and action tracking.

This helped uncover disconnected data views, repeated manual checks, unclear ownership of actions, and gaps in visibility between planning, procurement, and operations teams.

Mapping User Flows to Uncover Hidden Gaps

We mapped the complete S&OP lifecycle from demand capture and procurement inputs to review, approvals, and action tracking.

This helped uncover disconnected data views, repeated manual checks, unclear ownership of actions, and gaps in visibility between planning, procurement, and operations teams.

Mapping User Flows to Uncover Hidden Gaps

We mapped the complete S&OP lifecycle from demand capture and procurement inputs to review, approvals, and action tracking.

This helped uncover disconnected data views, repeated manual checks, unclear ownership of actions, and gaps in visibility between planning, procurement, and operations teams.

Designing S&OP Into a Unified Planning Workflow

Designing S&OP Into a Unified Planning Workflow

Designing S&OP Into a Unified Planning Workflow

We redesigned pharma S&OP from scattered spreadsheets into a structured, cross-functional workflow. Unified data, clear planning stages, and role-based inputs improved visibility, reduced manual reconciliation, and enabled faster, more confident planning decisions across teams.

We redesigned pharma S&OP from scattered spreadsheets into a structured, cross-functional workflow. Unified data, clear planning stages, and role-based inputs improved visibility, reduced manual reconciliation, and enabled faster, more confident planning decisions across teams.

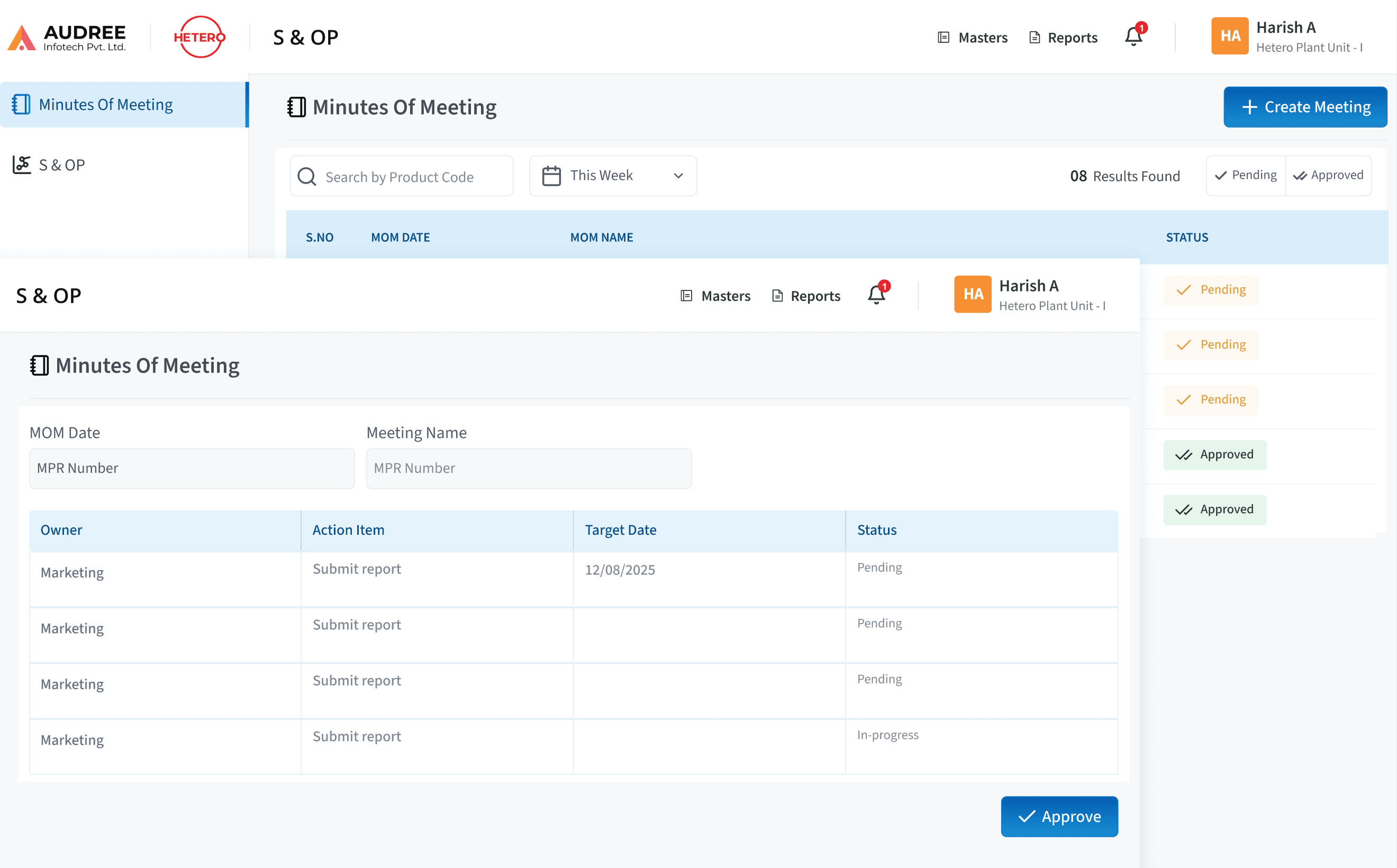

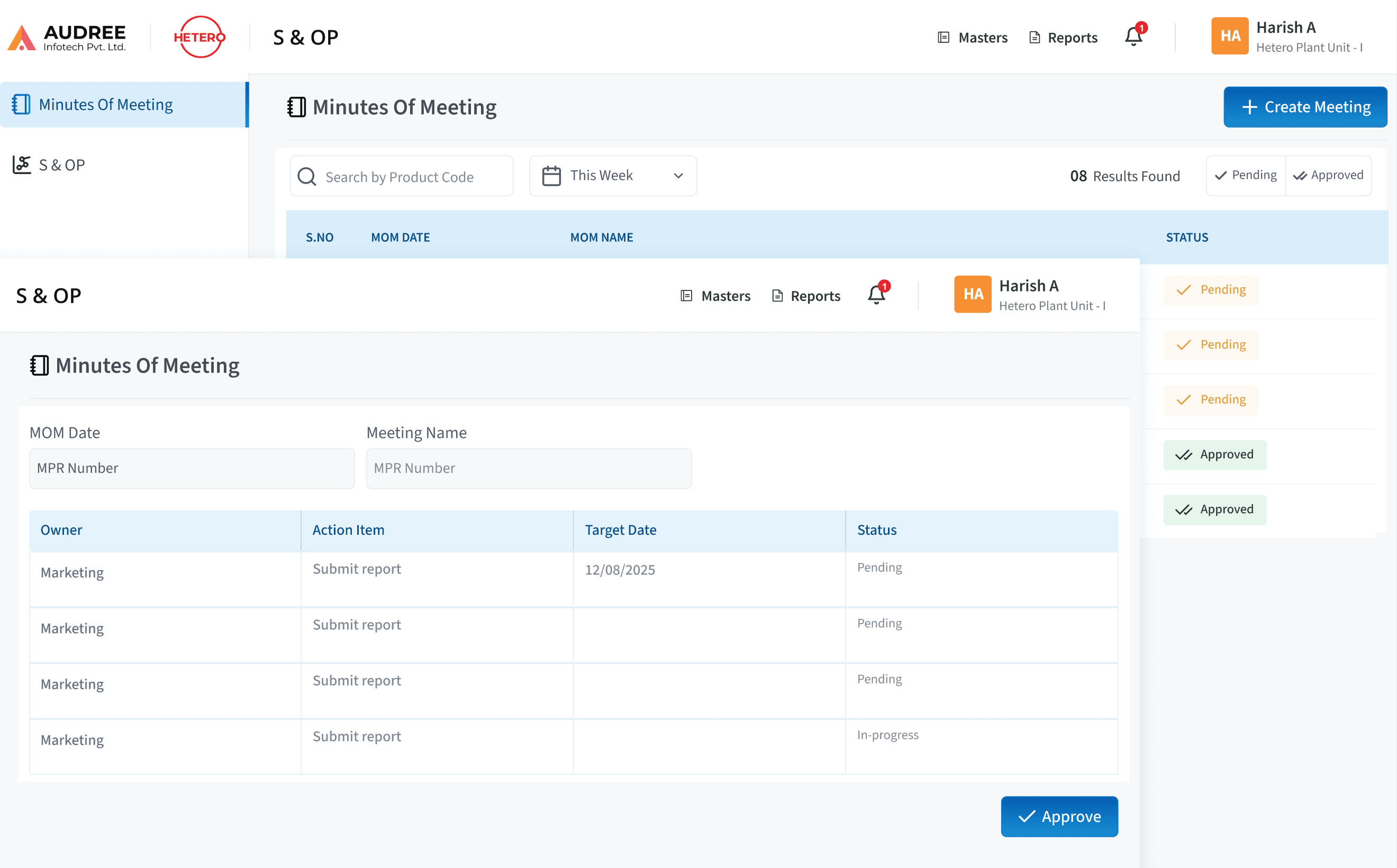

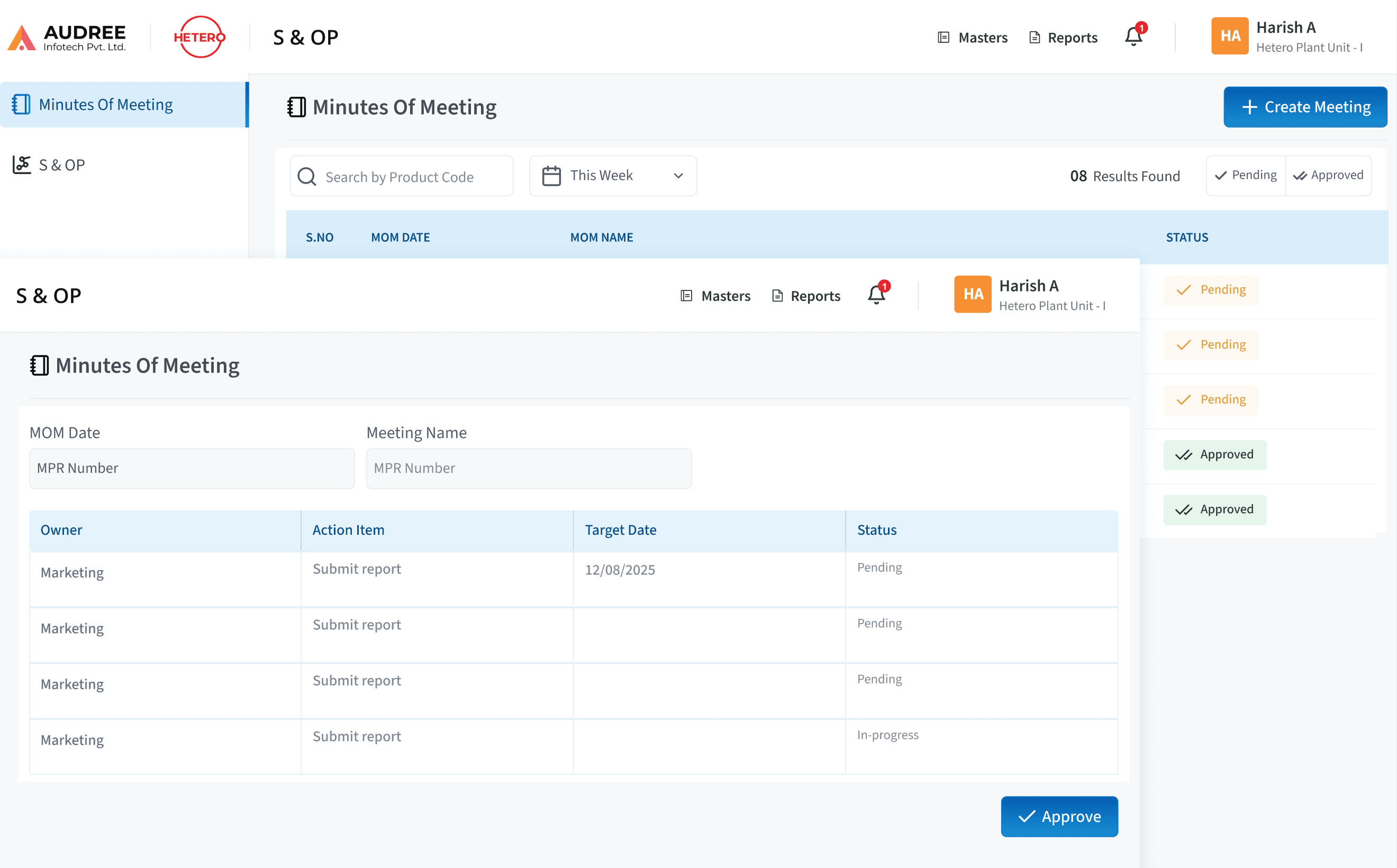

Structured S&OP Meeting Initiation for Accurate Planning

Structured S&OP Meeting Initiation for Accurate Planning

Structured S&OP Meeting Initiation for Accurate Planning

We redesigned the S&OP meeting workflow to bring structure and accountability to planning discussions. Instead of scattered notes and offline follow-ups, meetings are now created and approved within a single digital flow.

Clear MOM records, action items, owners, target dates ensure every planning decision is captured accurately. This enables teams to track commitments, monitor progress, and close actions without manual coordination.

We redesigned the S&OP meeting workflow to bring structure and accountability to planning discussions. Instead of scattered notes and offline follow-ups, meetings are now created and approved within a single digital flow.

Clear MOM records, action items, owners, target dates ensure every planning decision is captured accurately. This enables teams to track commitments, monitor progress, and close actions without manual coordination.

We redesigned the S&OP meeting workflow to bring structure and accountability to planning discussions. Instead of scattered notes and offline follow-ups, meetings are now created and approved within a single digital flow.

Clear MOM records, action items, owners, target dates ensure every planning decision is captured accurately. This enables teams to track commitments, monitor progress, and close actions without manual coordination.

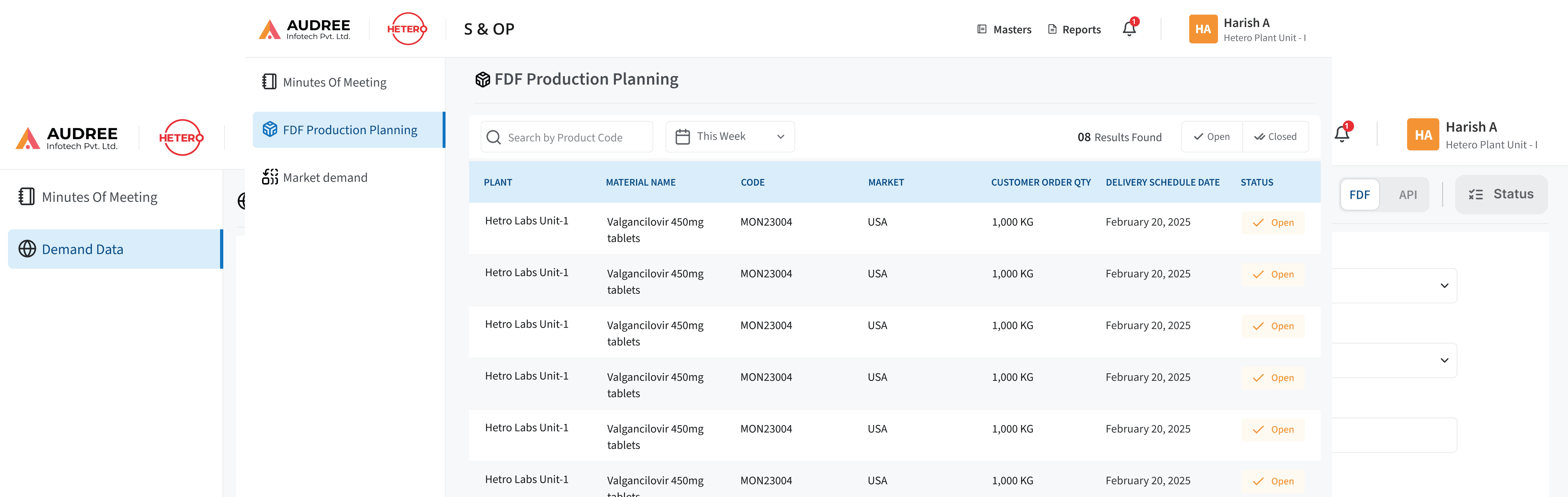

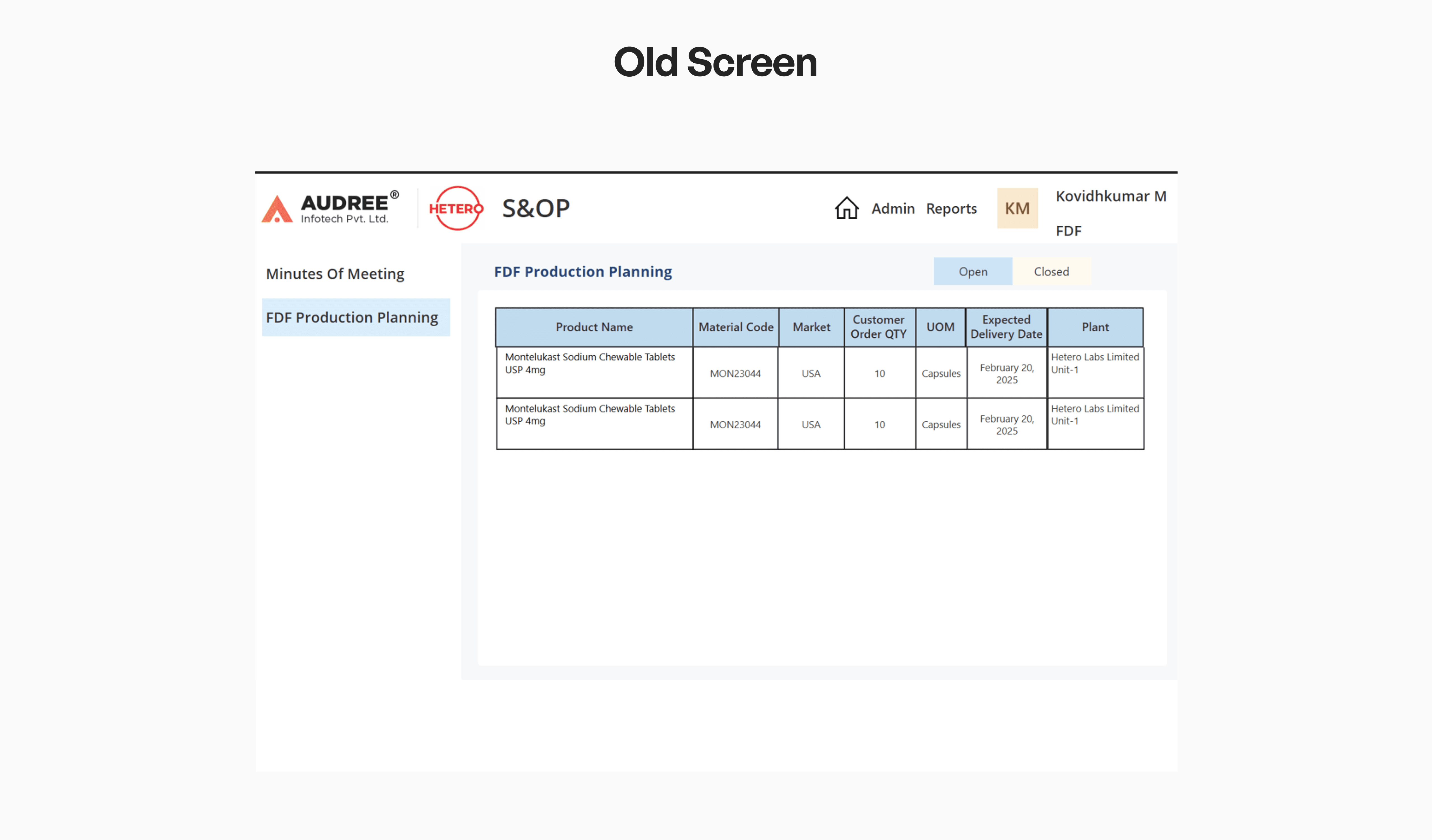

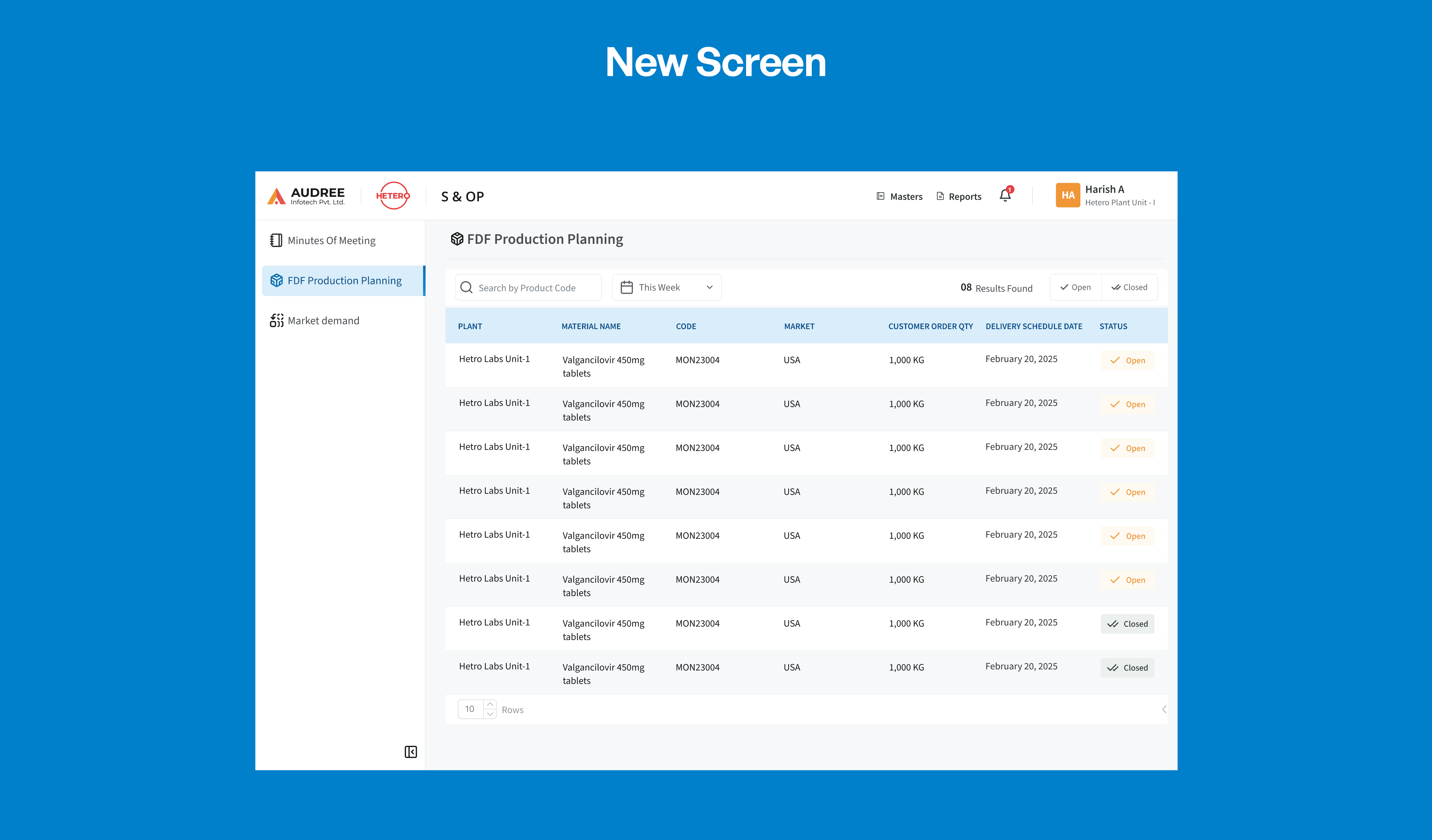

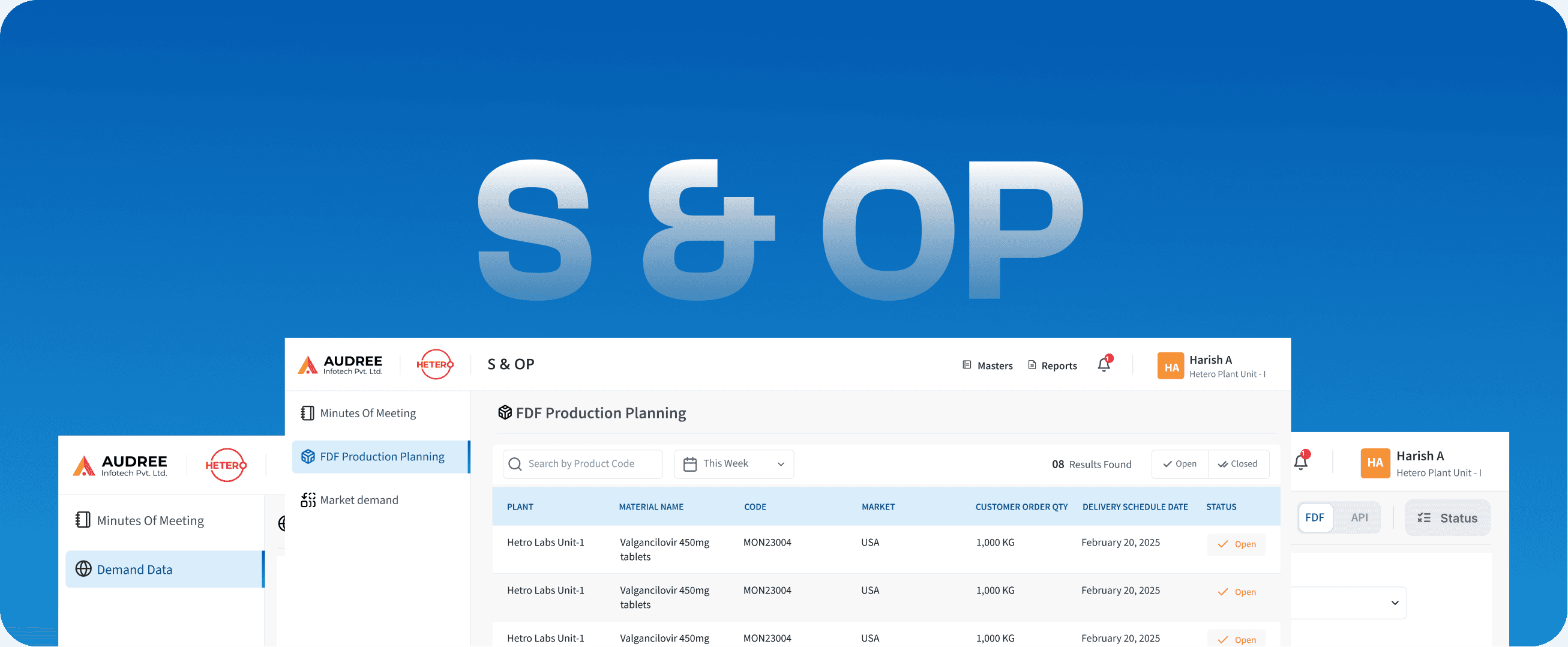

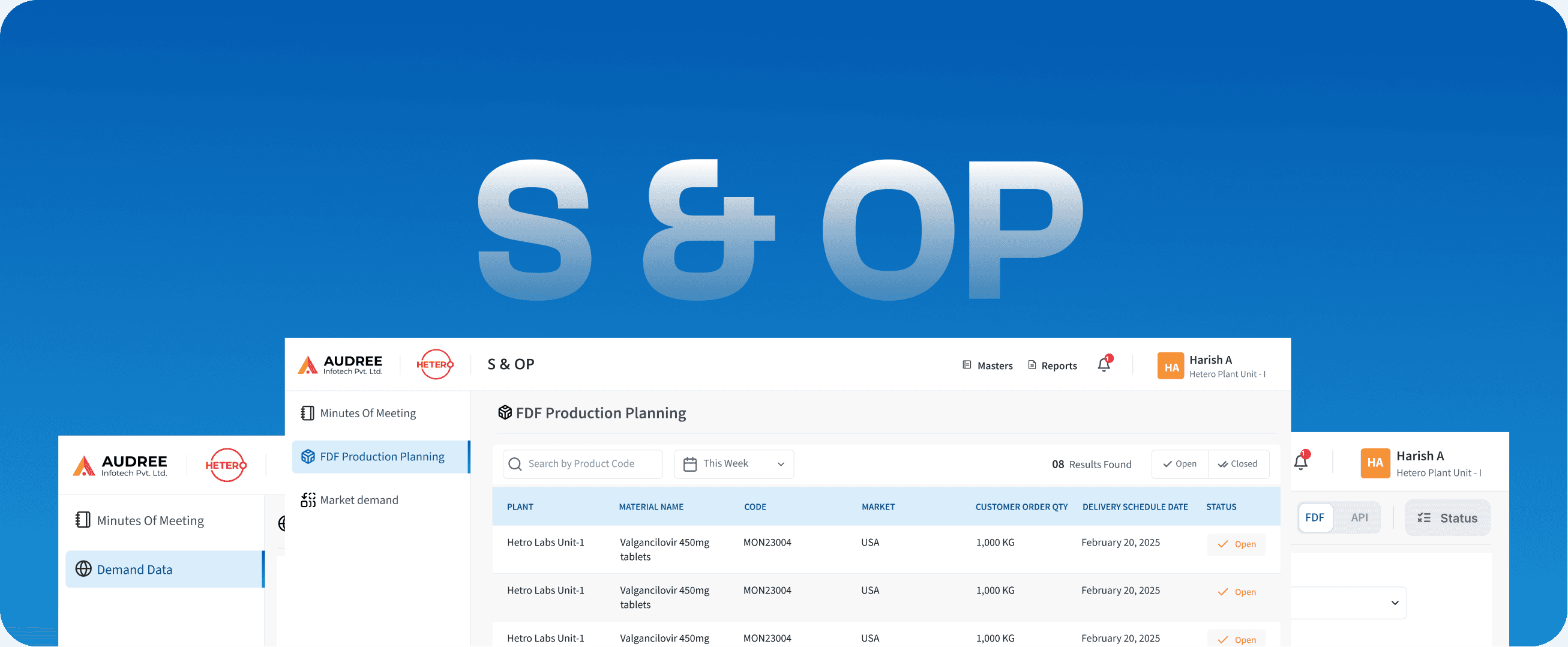

Structured View for Sales And Operations

Structured View for Sales And Operations

Structured View for Sales And Operations

We designed the S&OP module to provide a clear, structured view of sales and operational data across plants and products. Advance filter allow teams to quickly narrow down relevant records without relying on external spreadsheets.

Centralized tables bring product availability, material codes, and plant data into a single view, enabling quicker reviews and informed S&OP decisions. This clear visibility reduces manual coordination and repeated follow-ups during planning cycles.

We designed the S&OP module to provide a clear, structured view of sales and operational data across plants and products. Advance filter allow teams to quickly narrow down relevant records without relying on external spreadsheets.

Centralized tables bring product availability, material codes, and plant data into a single view, enabling quicker reviews and informed S&OP decisions. This clear visibility reduces manual coordination and repeated follow-ups during planning cycles.

We designed the S&OP module to provide a clear, structured view of sales and operational data across plants and products. Advance filter allow teams to quickly narrow down relevant records without relying on external spreadsheets.

Centralized tables bring product availability, material codes, and plant data into a single view, enabling quicker reviews and informed S&OP decisions. This clear visibility reduces manual coordination and repeated follow-ups during planning cycles.

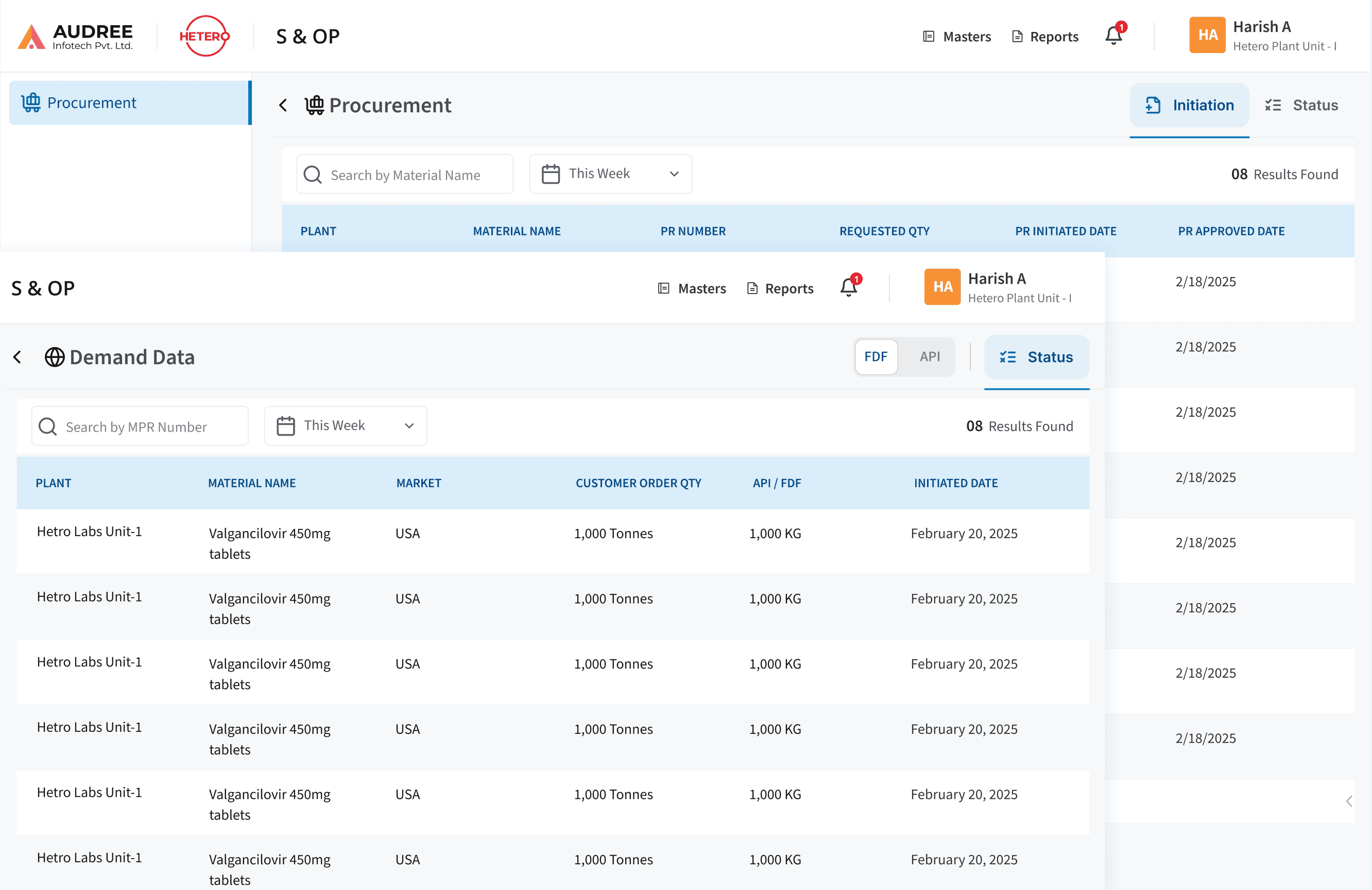

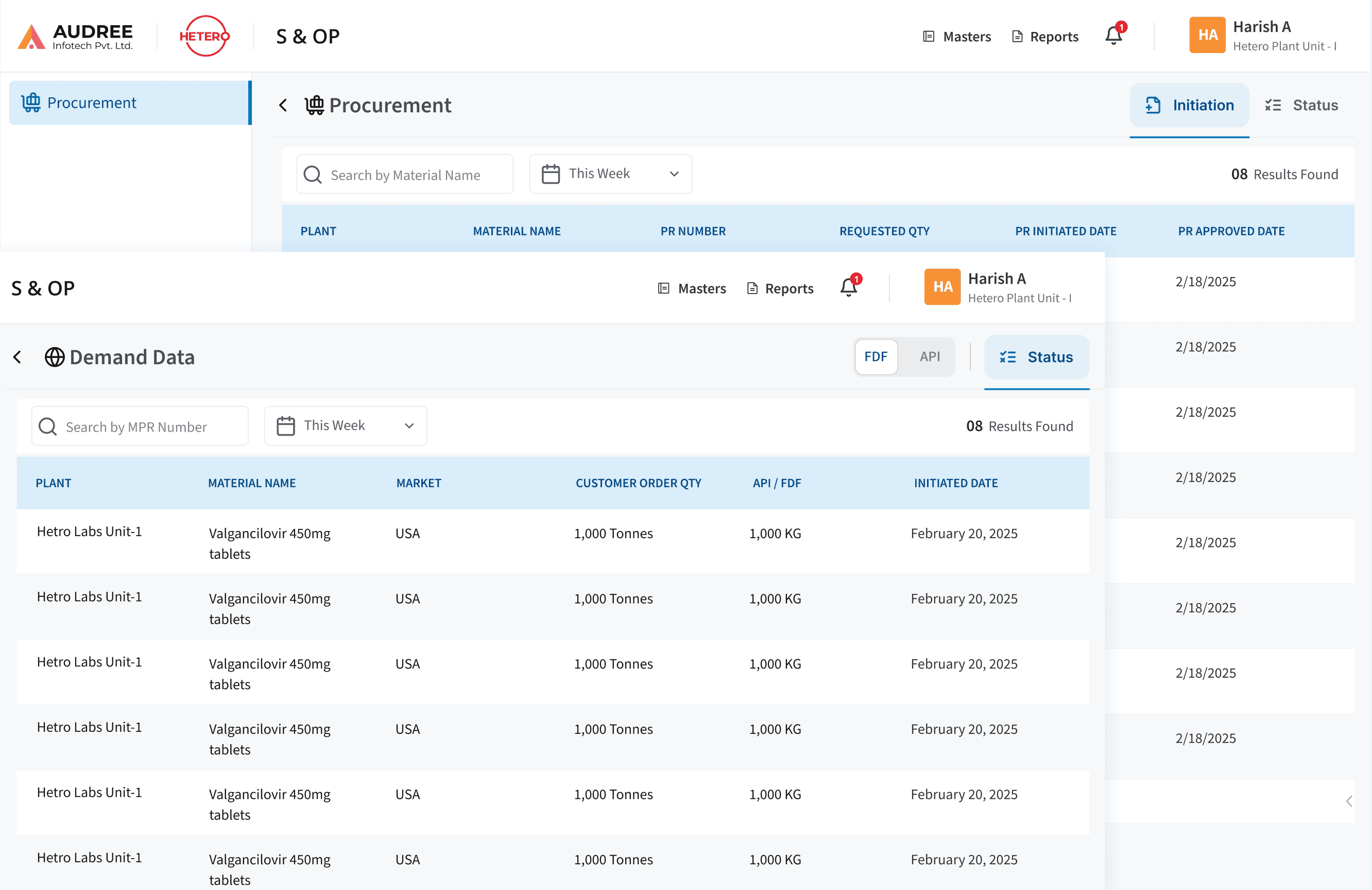

Clear Demand & Procurement Views for Confident Planning

Clear Demand & Procurement Views for Confident Planning

Clear Demand & Procurement Views for Confident Planning

Dedicated views for Procurement and Demand present critical planning data in a structured, easy-to-scan format.

In the Demand view, a simple FDF / API toggle allows users to switch instantly between finished dosage and API demand. This makes it easier to analyse requirements, compare volumes, and plan accurately without jumping between screens or reports.

Dedicated views for Procurement and Demand present critical planning data in a structured, easy-to-scan format.

In the Demand view, a simple FDF / API toggle allows users to switch instantly between finished dosage and API demand. This makes it easier to analyse requirements, compare volumes, and plan accurately without jumping between screens or reports.

Dedicated views for Procurement and Demand present critical planning data in a structured, easy-to-scan format.

In the Demand view, a simple FDF / API toggle allows users to switch instantly between finished dosage and API demand. This makes it easier to analyse requirements, compare volumes, and plan accurately without jumping between screens or reports.

A Cleaner UI for Faster, Confident Execution

A Cleaner UI for Faster, Confident Execution

A Cleaner UI for Faster, Confident Execution

The redesigned screens focus on clarity and consistency. Clean layouts, standardized fields, and clear visual cues help users understand context quickly and take the right actions without rework.

The redesigned screens focus on clarity and consistency. Clean layouts, standardized fields, and clear visual cues help users understand context quickly and take the right actions without rework.

Results That Redefined S&OP Planning & Execution

Results That Redefined S&OP Planning & Execution

Results That Redefined S&OP Planning & Execution

Clear planning flows, centralised data views, and guided decision points transformed how sales, operations, and procurement teams plan, review, and act on supply–demand signals.

Clear planning flows, centralised data views, and guided decision points transformed how sales, operations, and procurement teams plan, review, and act on supply–demand signals.

Stronger Compliance & Traceability

Stronger Compliance & Traceability

Stronger Compliance & Traceability

Centralized demand, supply, and procurement views ensured every planning input, dependency, and decision was visible in one place. This improved alignment across teams and reduced planning blind spots.

Centralized demand, supply, and procurement views ensured every planning input, dependency, and decision was visible in one place. This improved alignment across teams and reduced planning blind spots.

Centralized demand, supply, and procurement views ensured every planning input, dependency, and decision was visible in one place. This improved alignment across teams and reduced planning blind spots.

Faster API Batch Execution

Clean tables, status indicators, and quick filters enabled teams to review demand signals, material availability, and procurement actions faster without relying on manual consolidation or offline analysis.

Fewer Support Tickets

Clear ownership, tracked actions, and up-to-date statuses minimized repeated clarifications and follow-ups. Planning discussions moved forward with clarity, accountability, and fewer delays.

Faster API Batch Execution

Faster API Batch Execution

Clean tables, status indicators, and quick filters enabled teams to review demand signals, material availability, and procurement actions faster without relying on manual consolidation or offline analysis.

Clean tables, status indicators, and quick filters enabled teams to review demand signals, material availability, and procurement actions faster without relying on manual consolidation or offline analysis.

Fewer Support Tickets

Fewer Support Tickets

Clear ownership, tracked actions, and up-to-date statuses minimized repeated clarifications and follow-ups. Planning discussions moved forward with clarity, accountability, and fewer delays.

Clear ownership, tracked actions, and up-to-date statuses minimized repeated clarifications and follow-ups. Planning discussions moved forward with clarity, accountability, and fewer delays.

Deep-Dive Into More System

Deep-Dive Into More System

Deep-Dive Into More System

Browse every optimised Software and explore how legacy systems became intuitive.

Browse every optimised Software and explore how legacy systems became intuitive.

Browse every optimised Software and explore how legacy systems became intuitive.

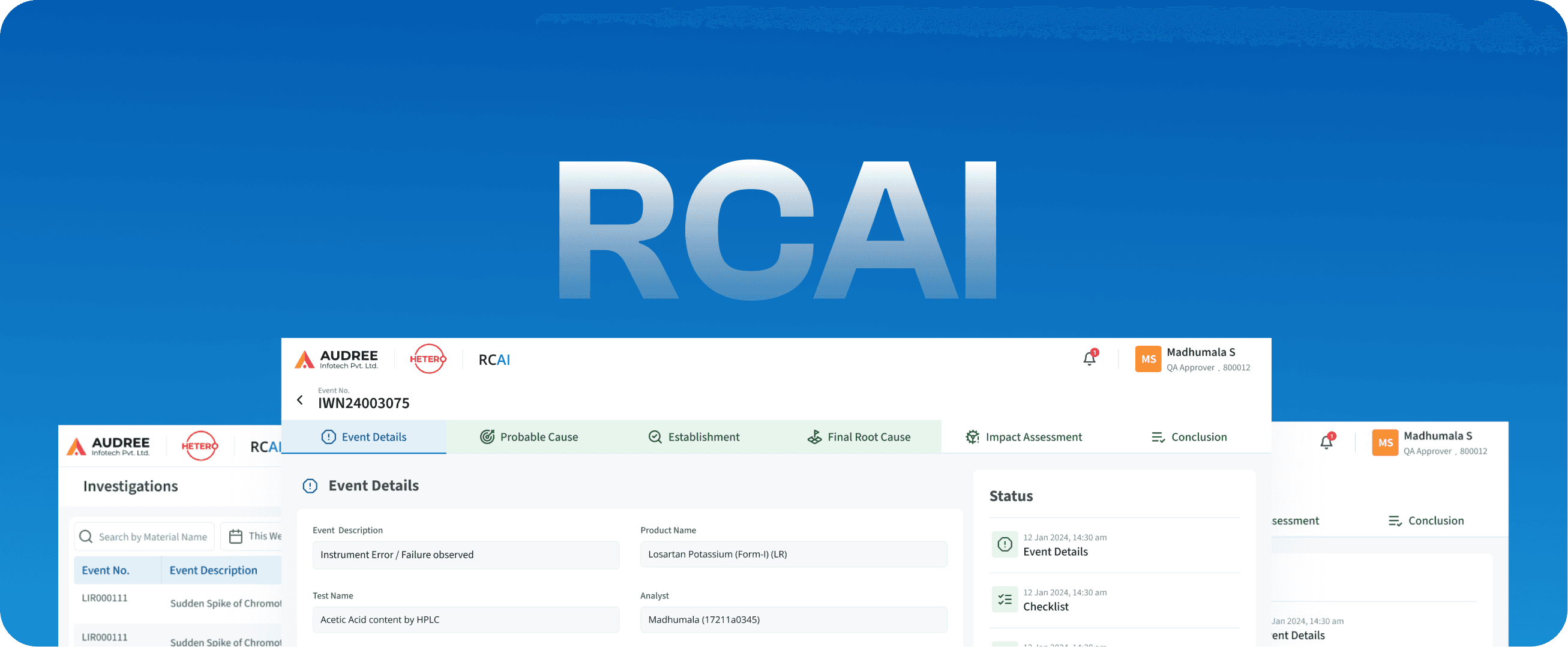

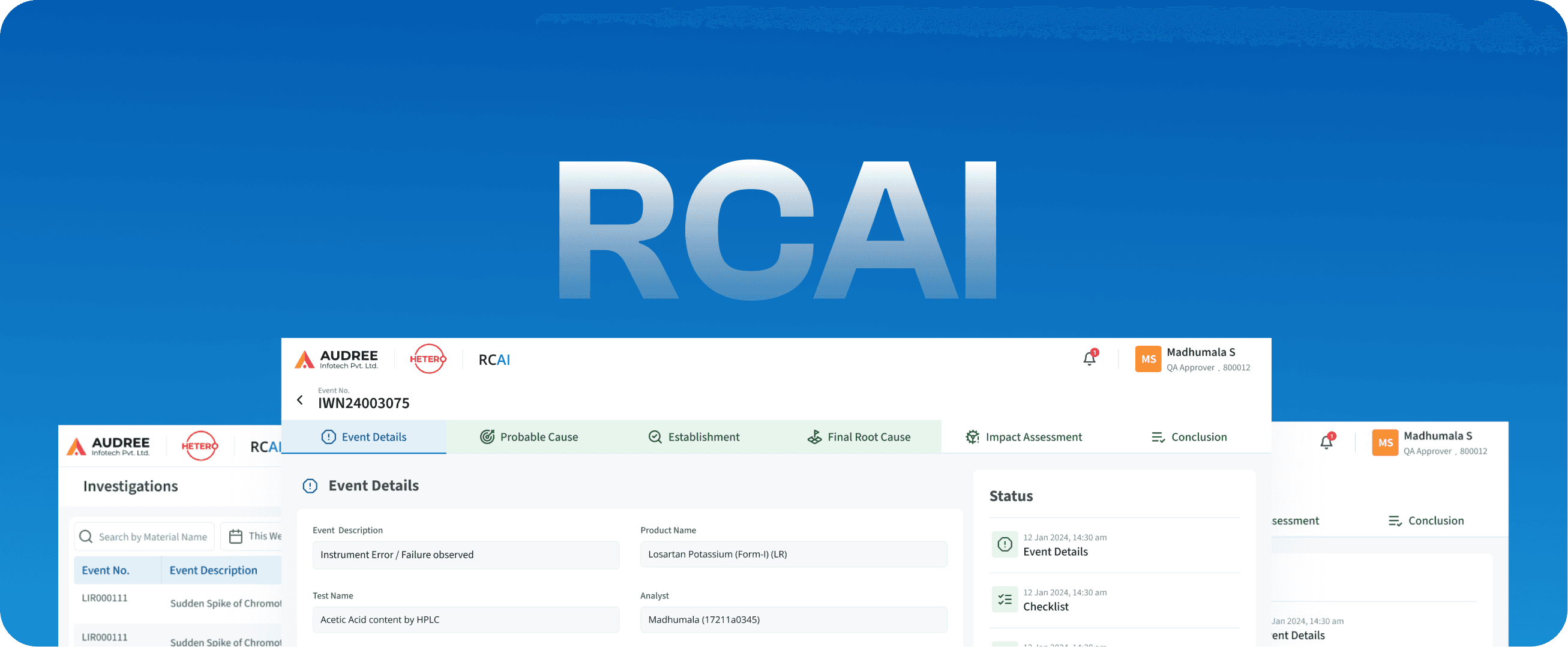

RCAI

Root Cause Analysis with Intelligence

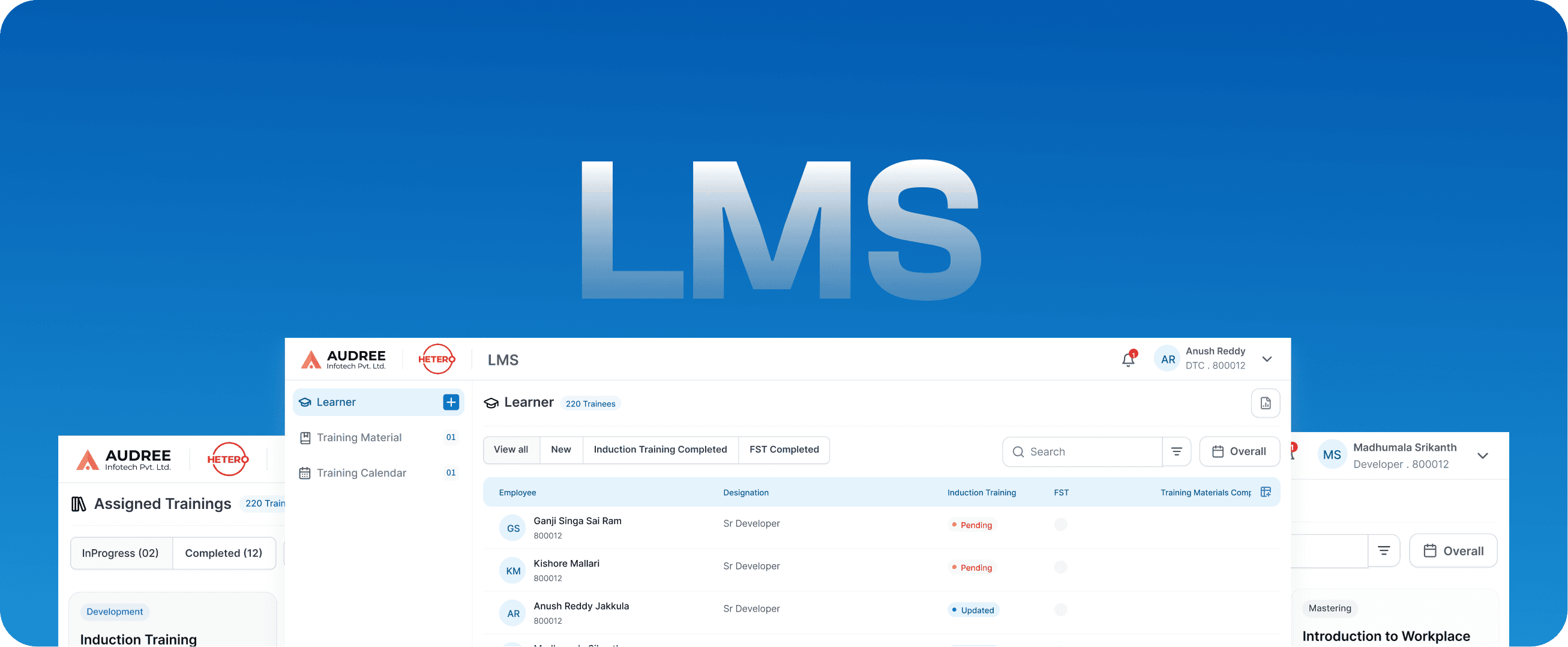

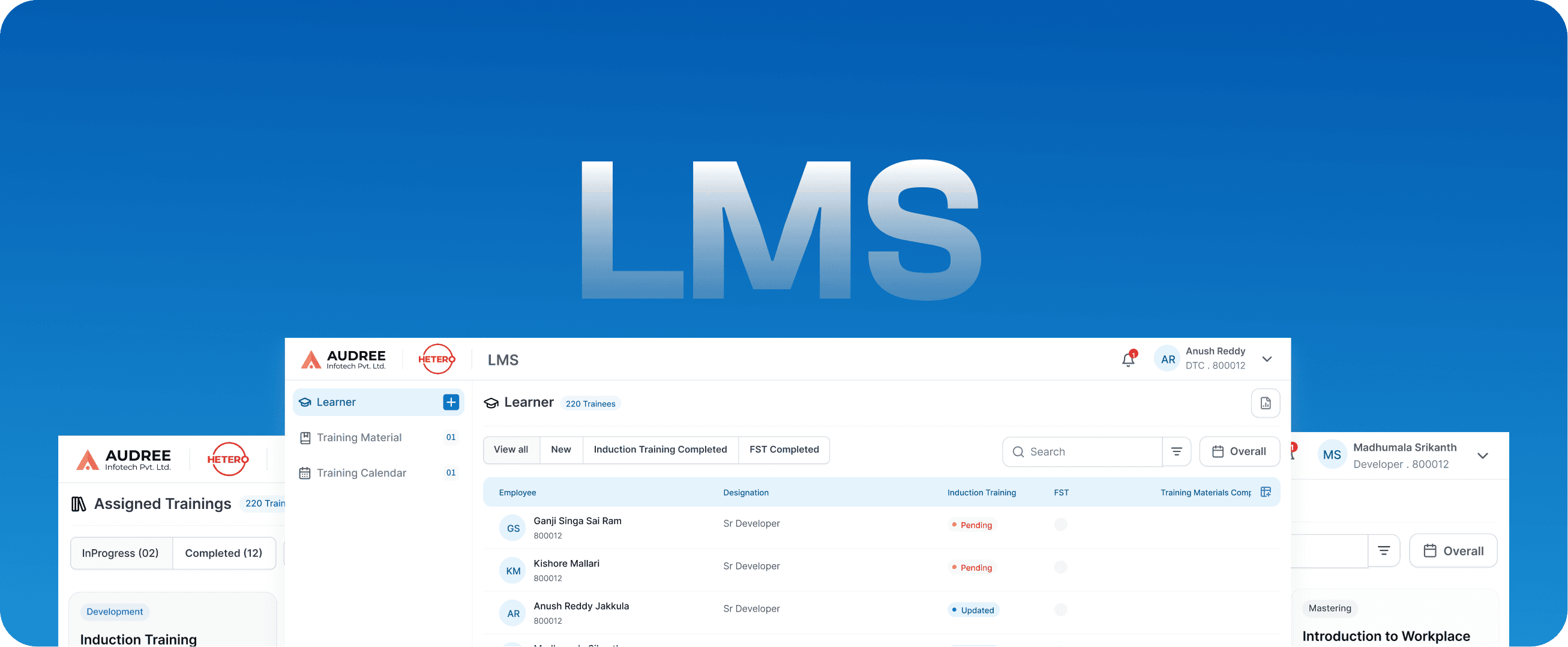

LMS

Learning Management System

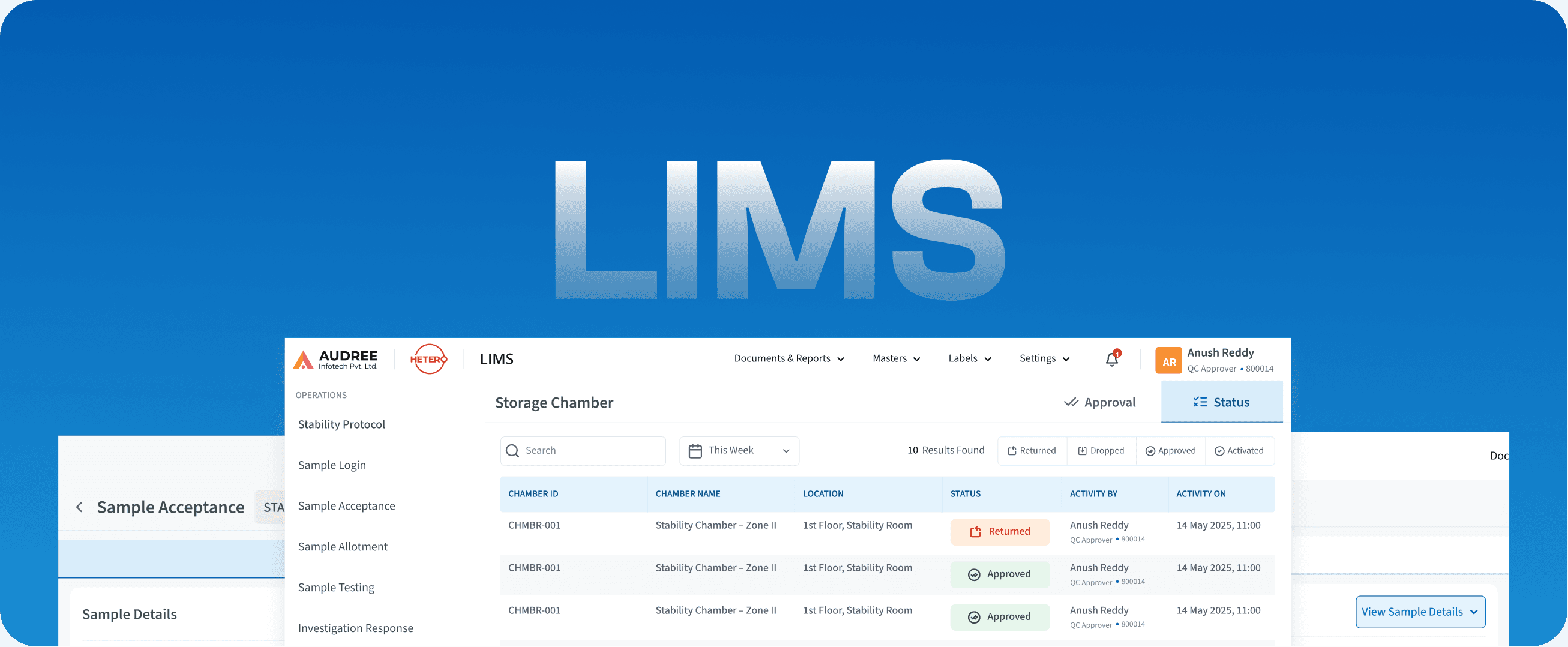

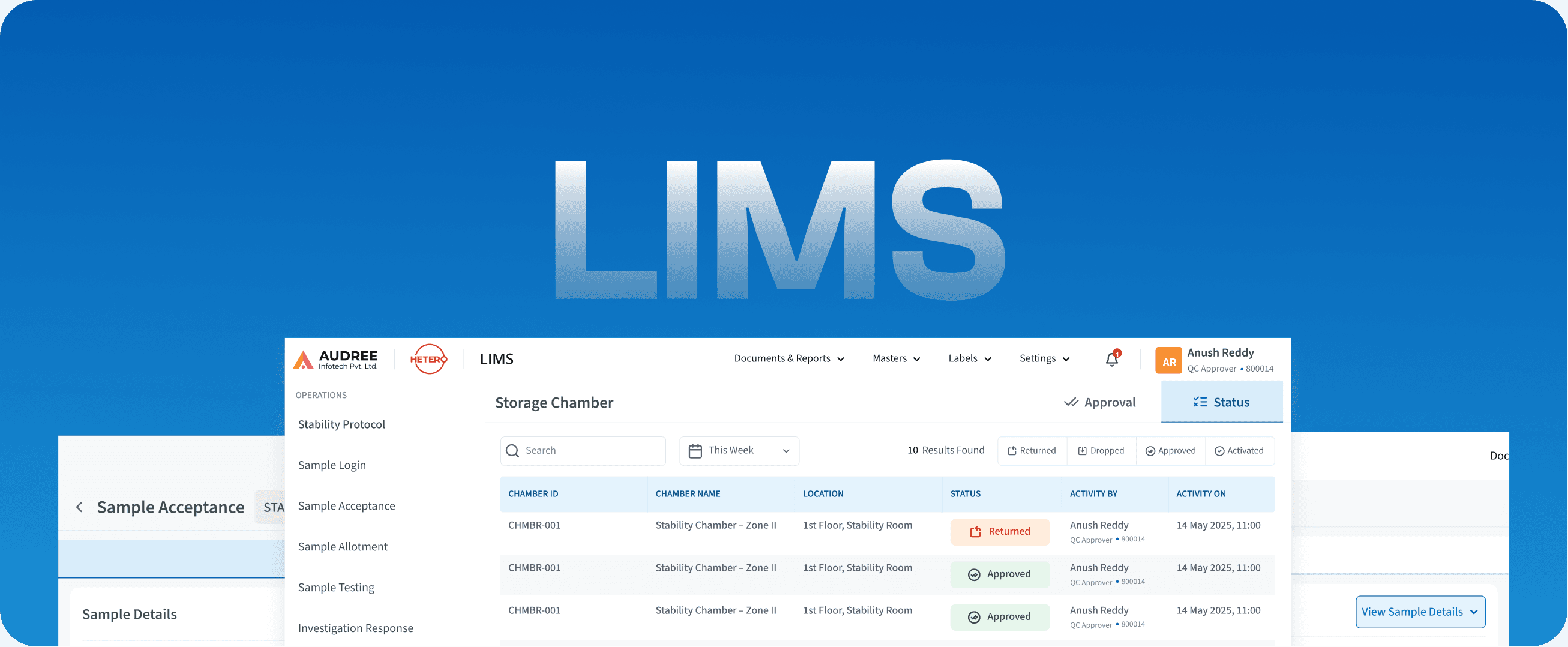

LIMS

Laboratory Information Management System

S & OP

Sales & Operations Planning

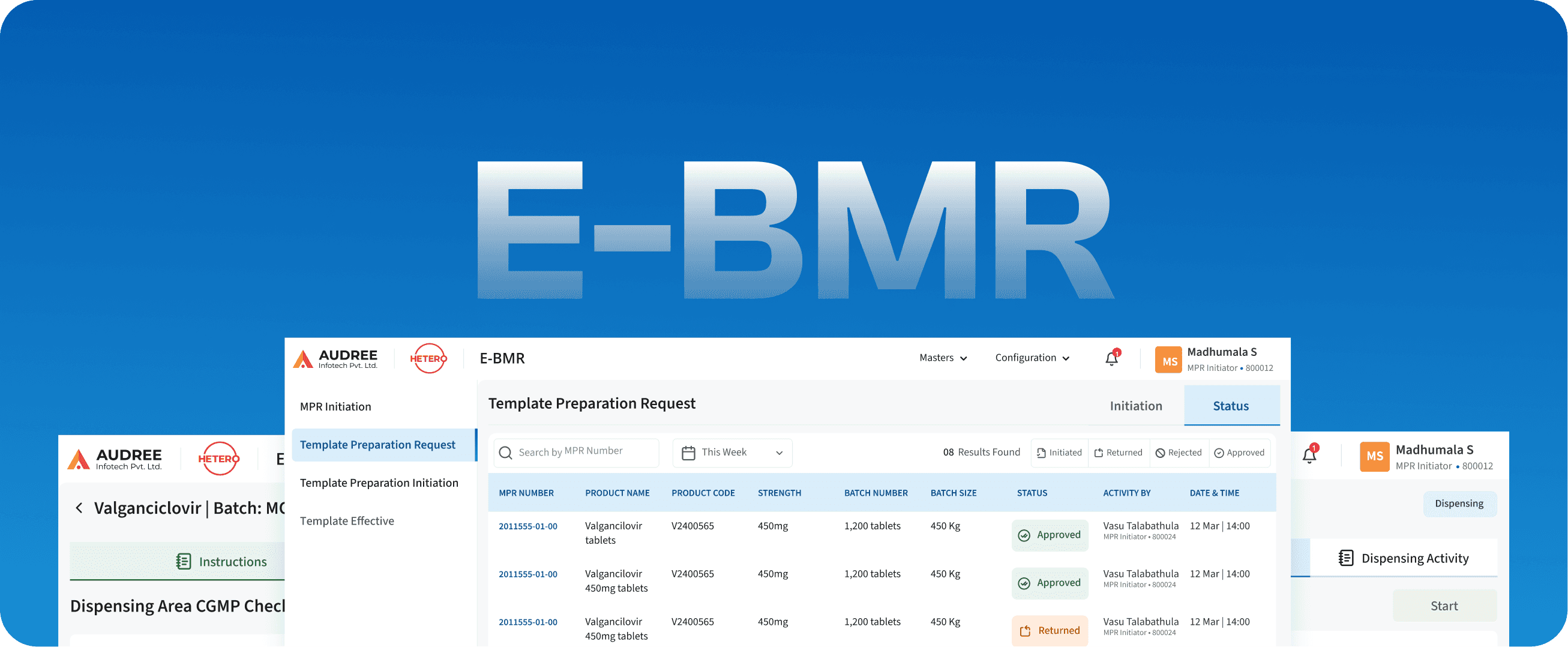

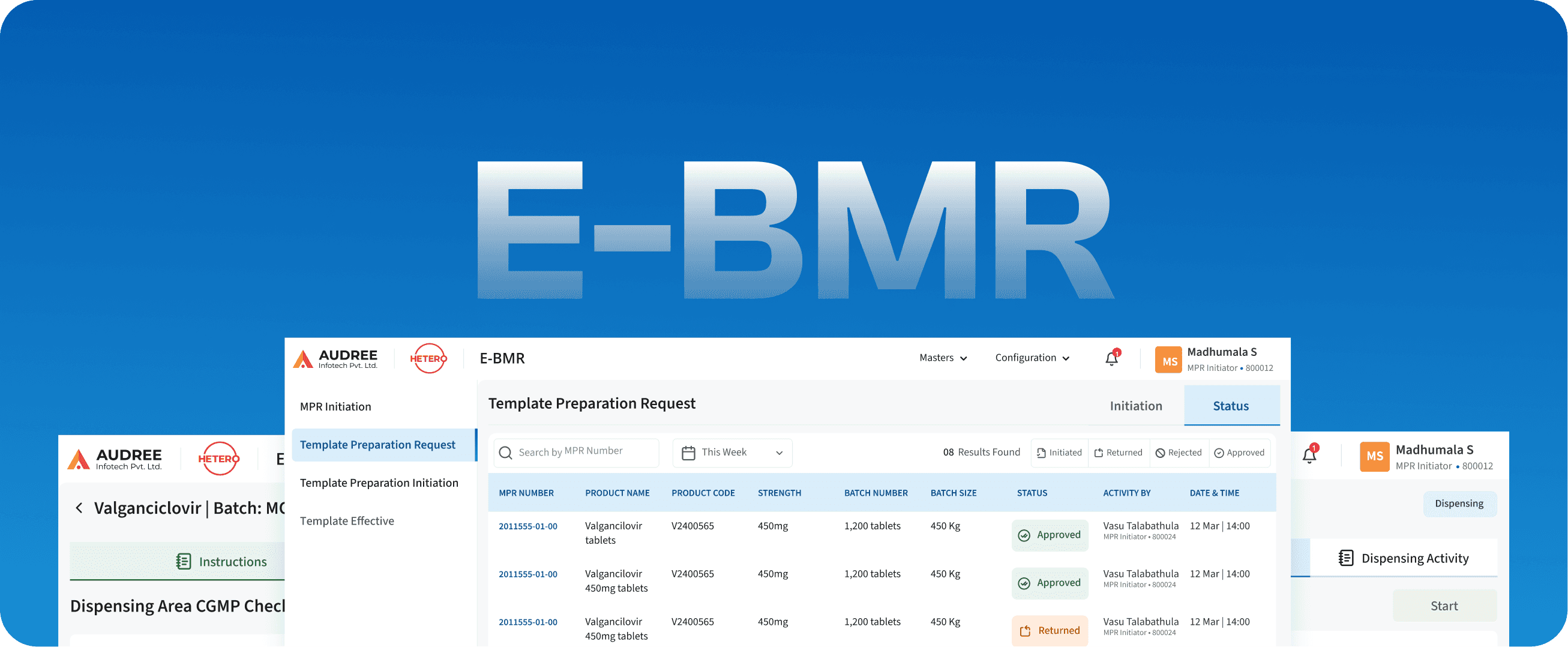

E-BMR

Batch Manufacturing Recall

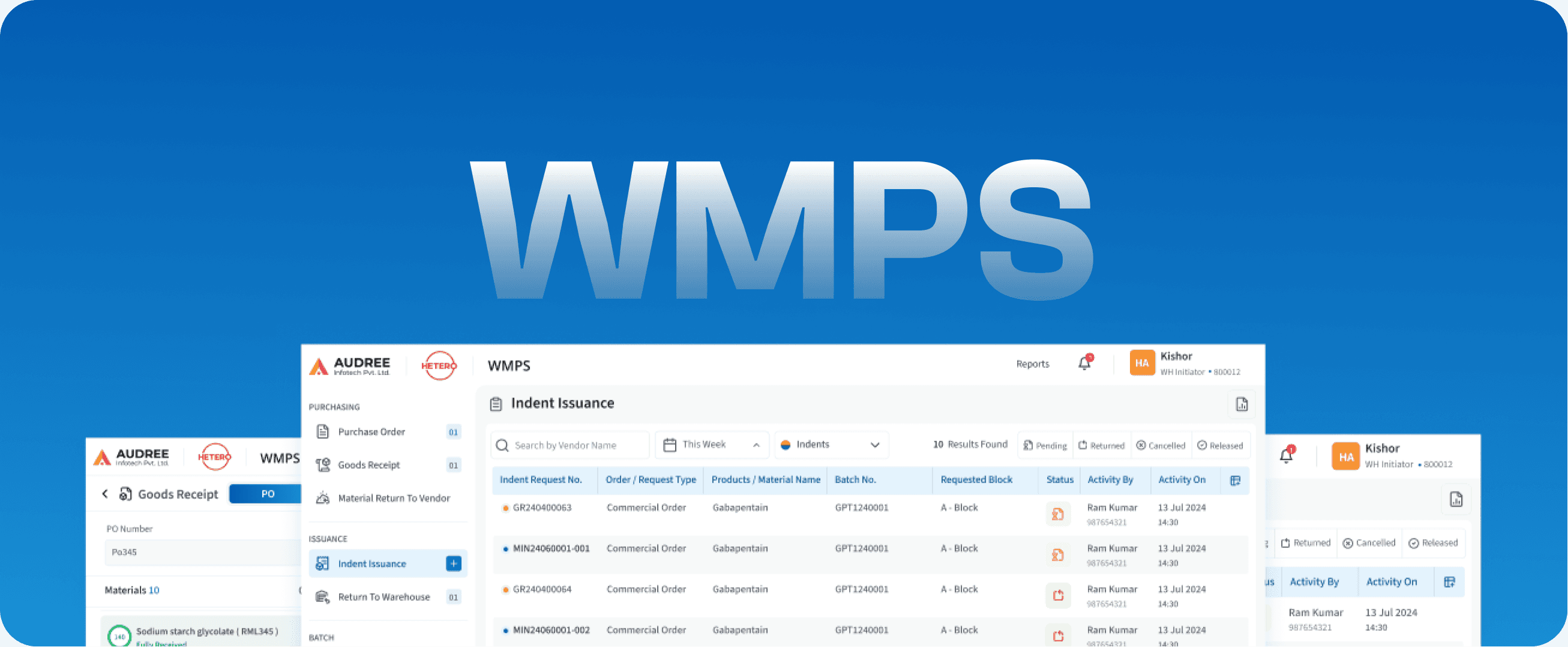

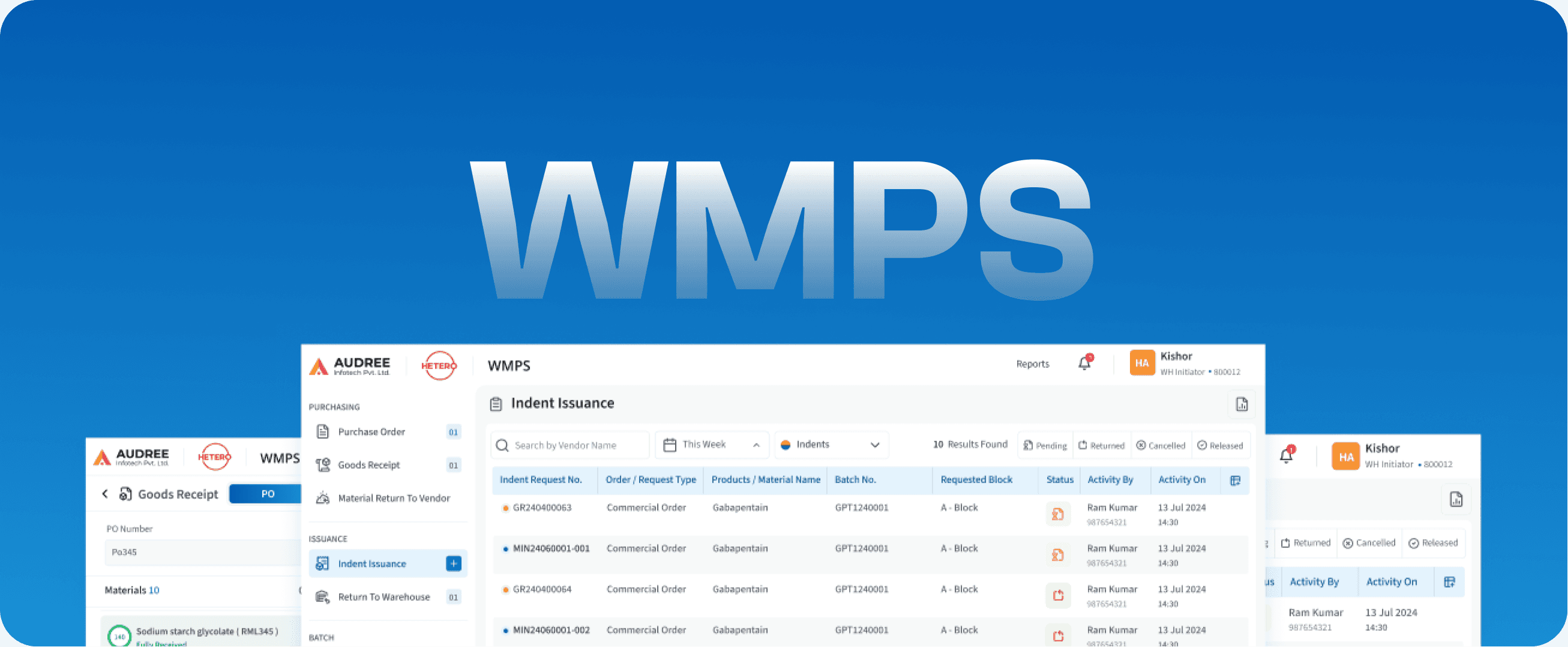

WMPS

Warehouse Management System

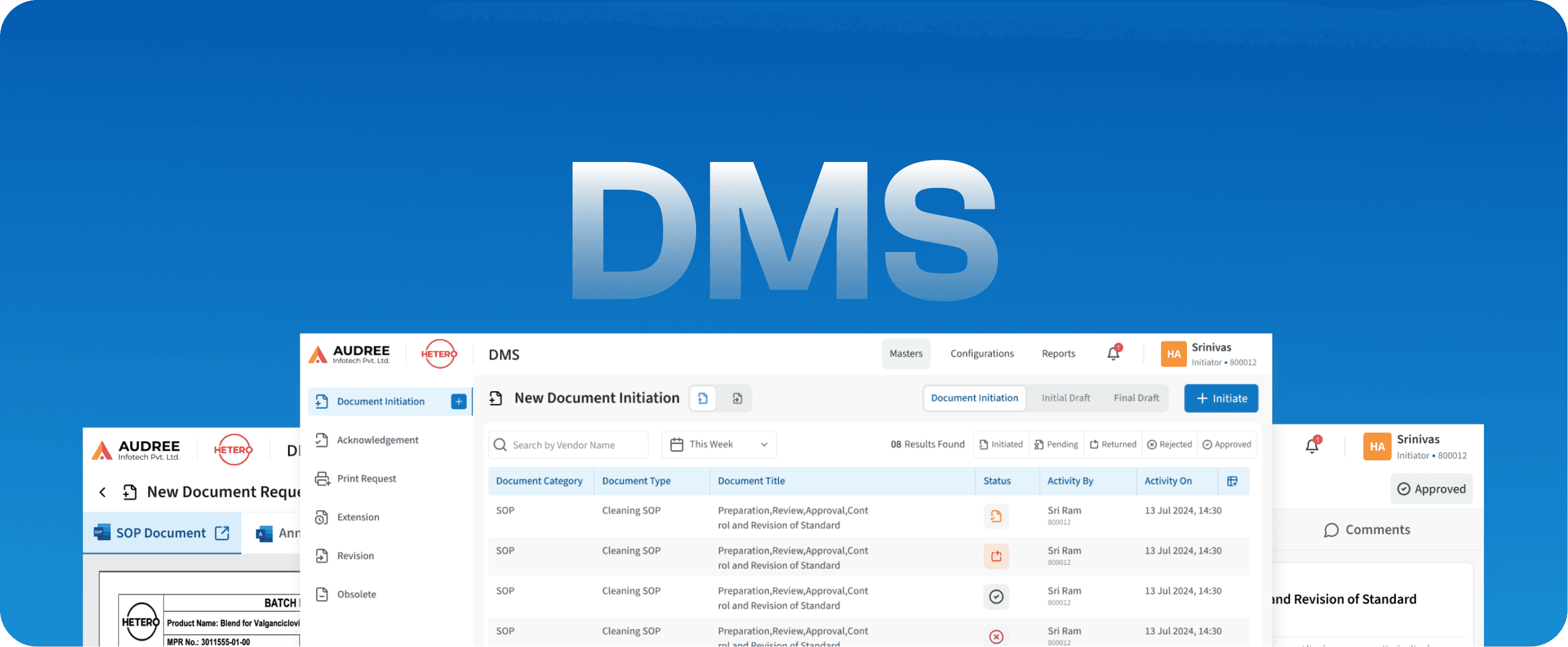

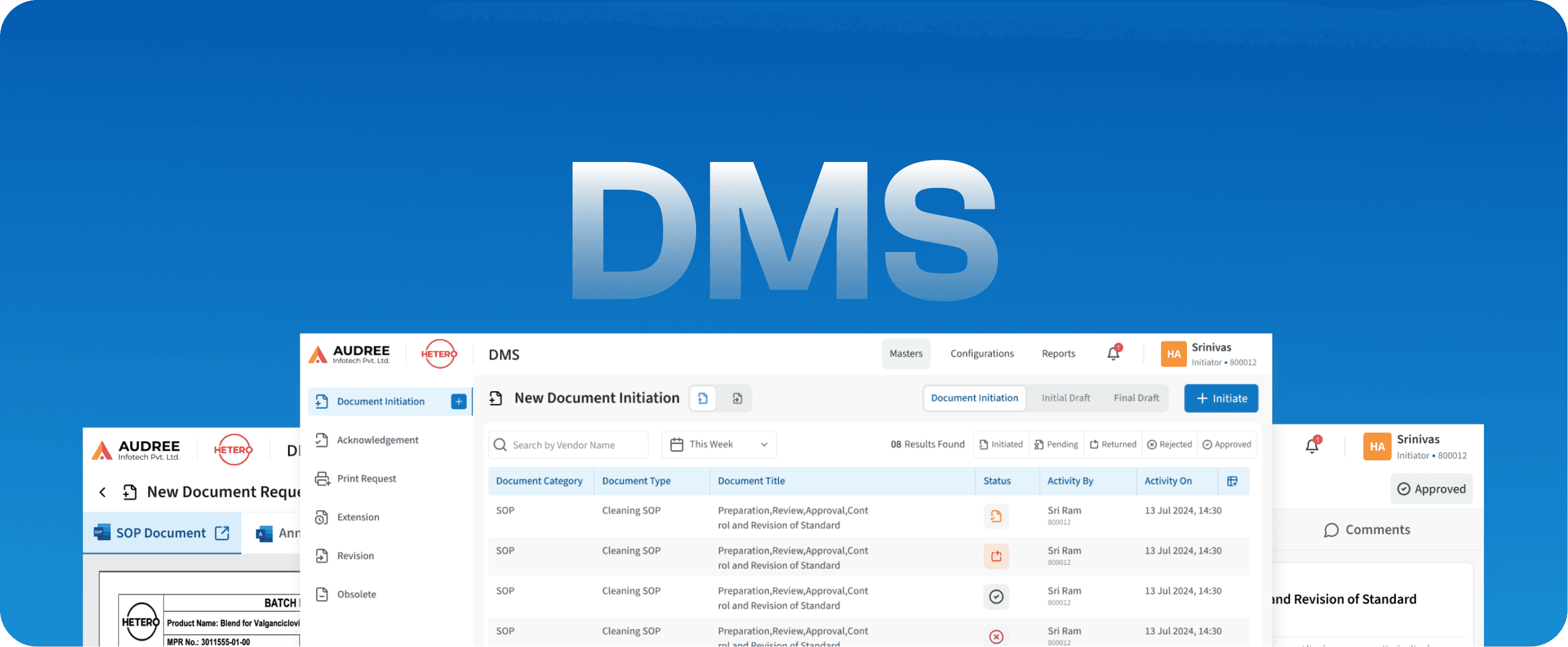

DMS

Document Management System

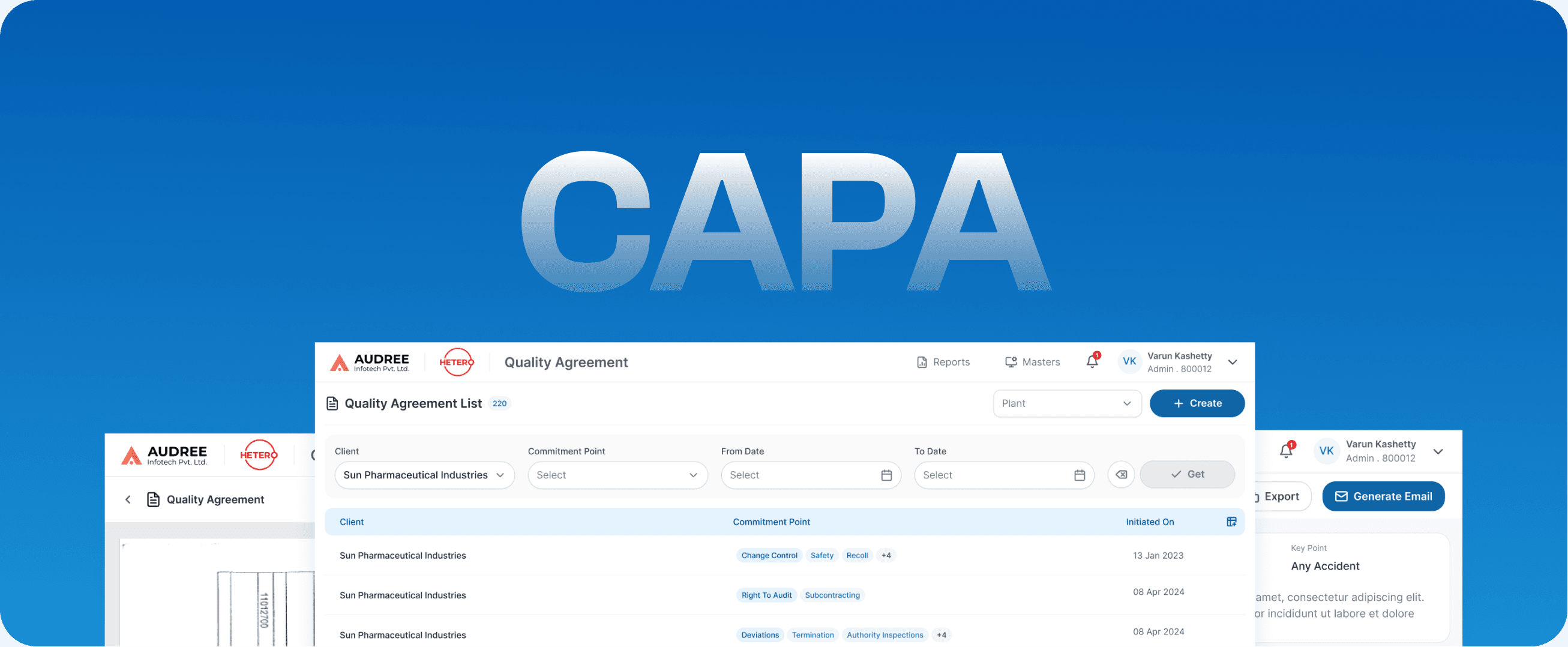

CAPA

Corrective And Preventive Actions

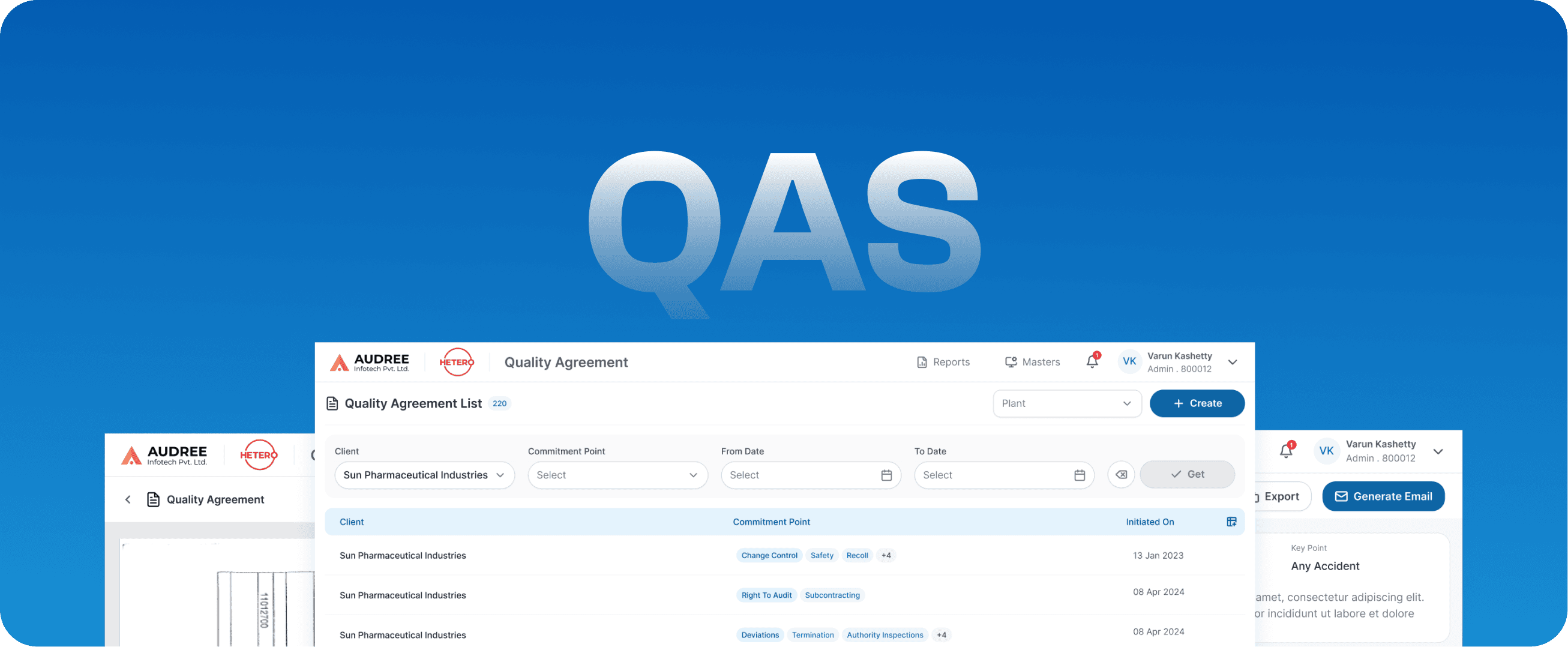

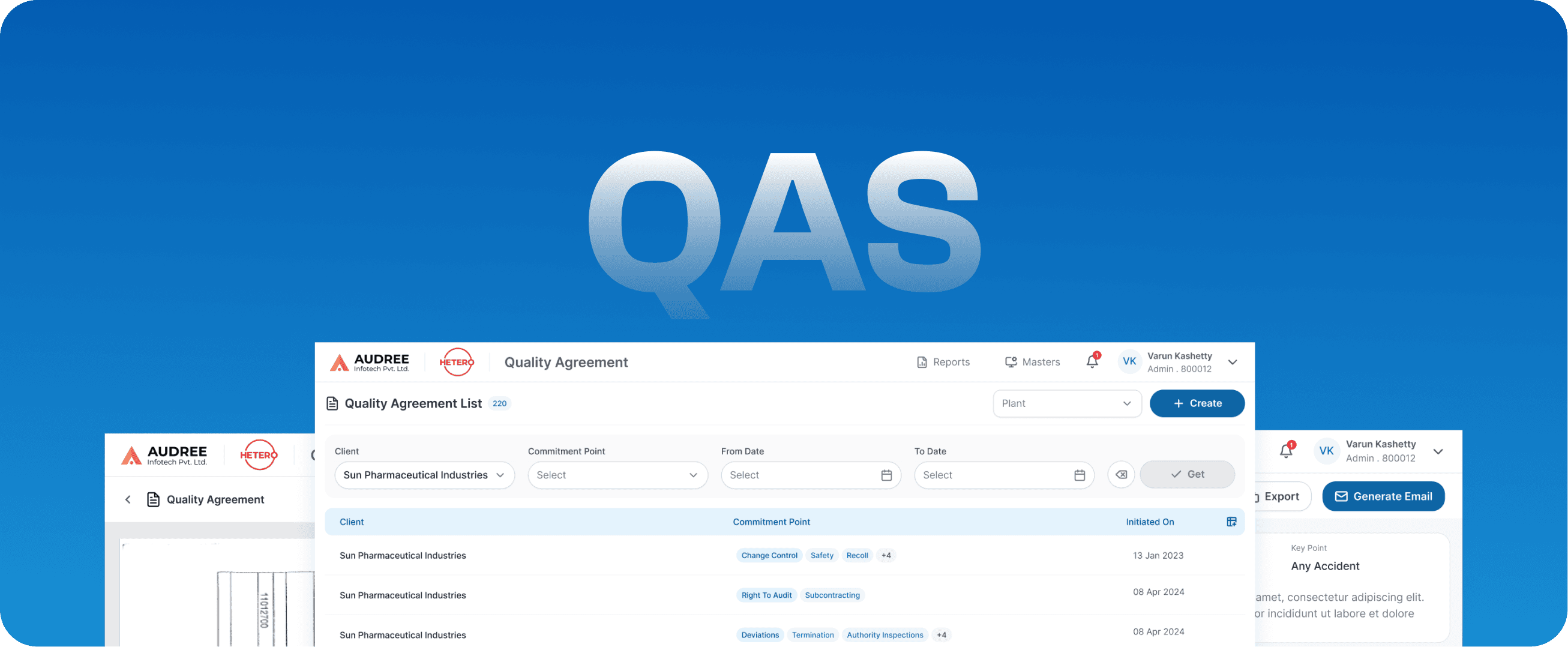

QAS

Quality Agreement System

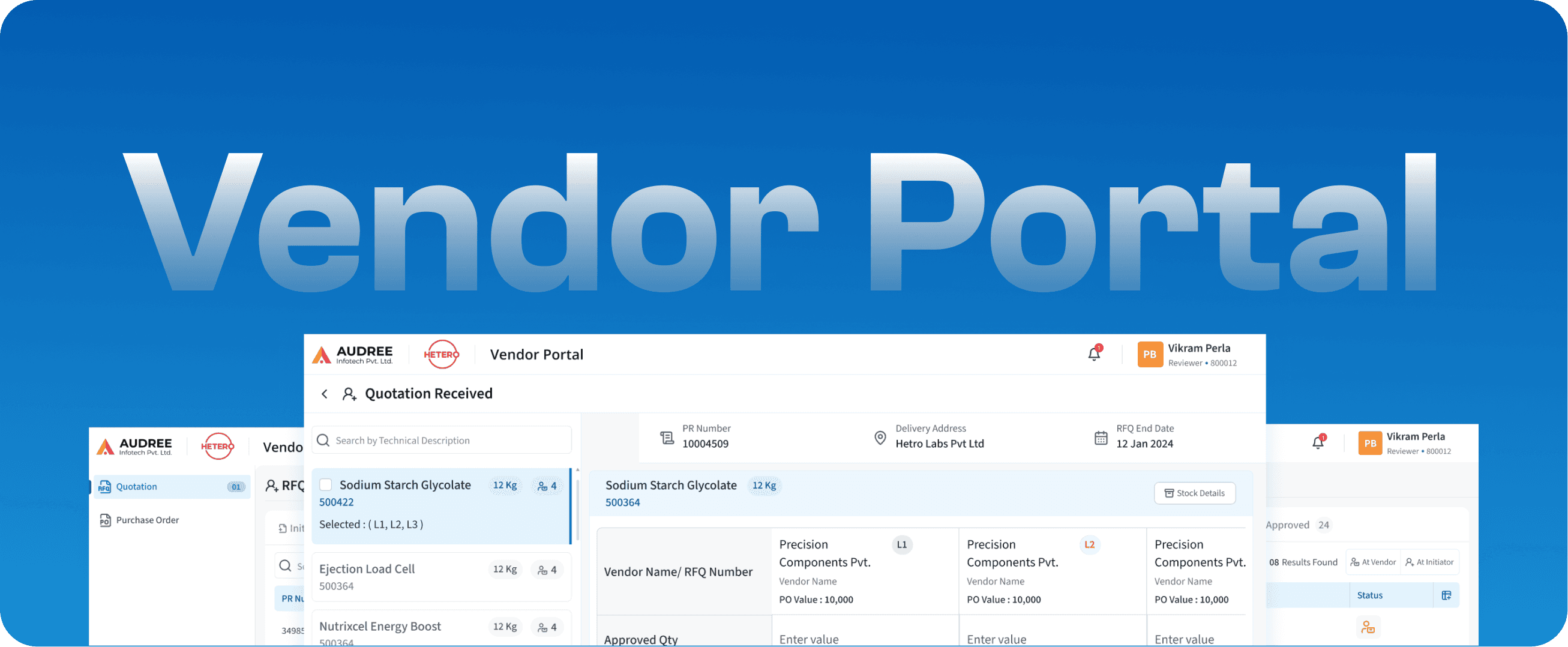

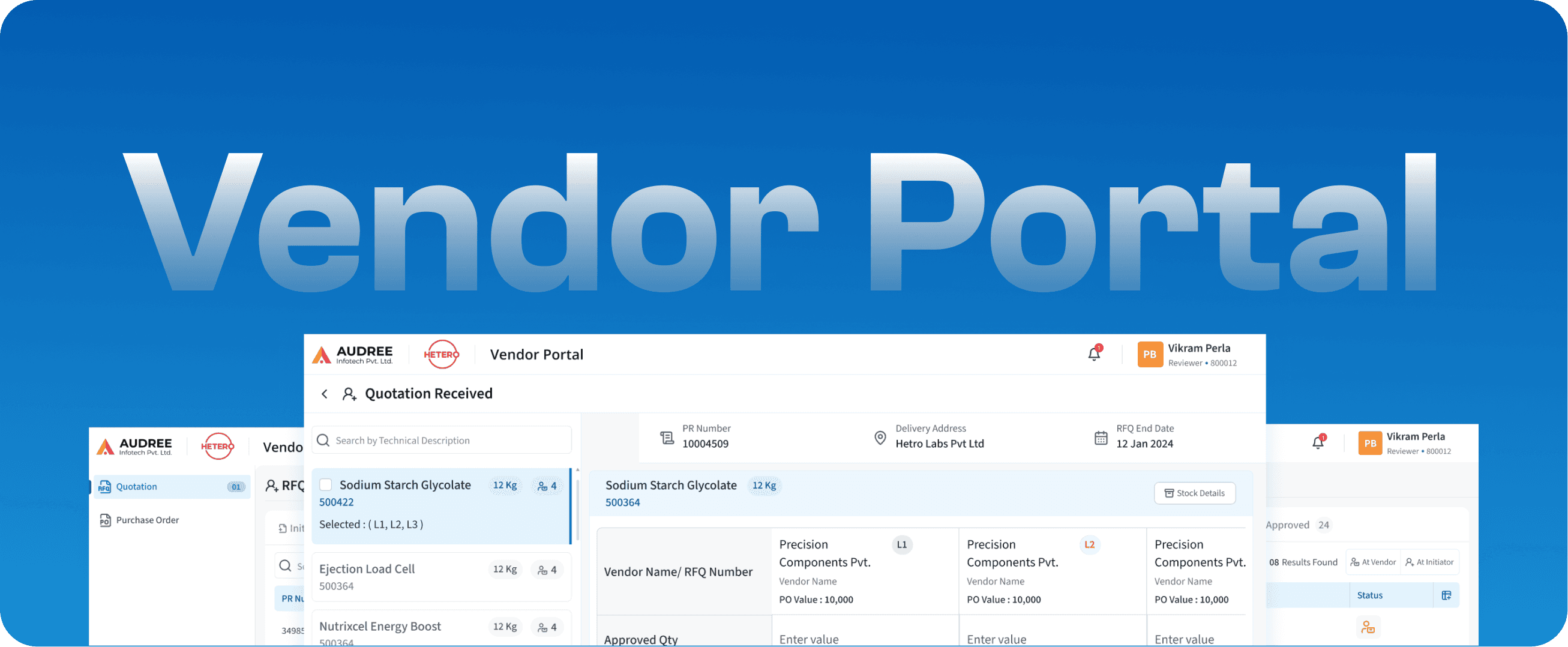

Vendor Portal

Vendor Management System

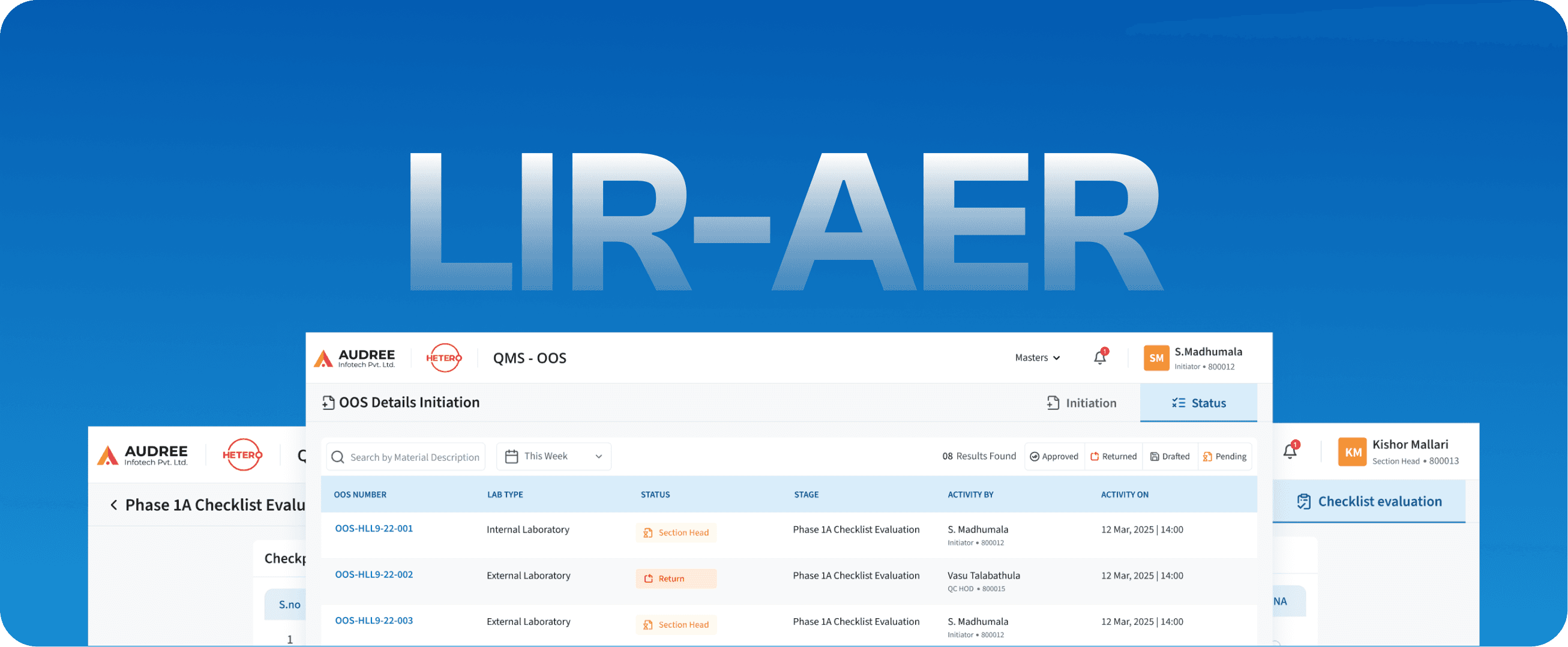

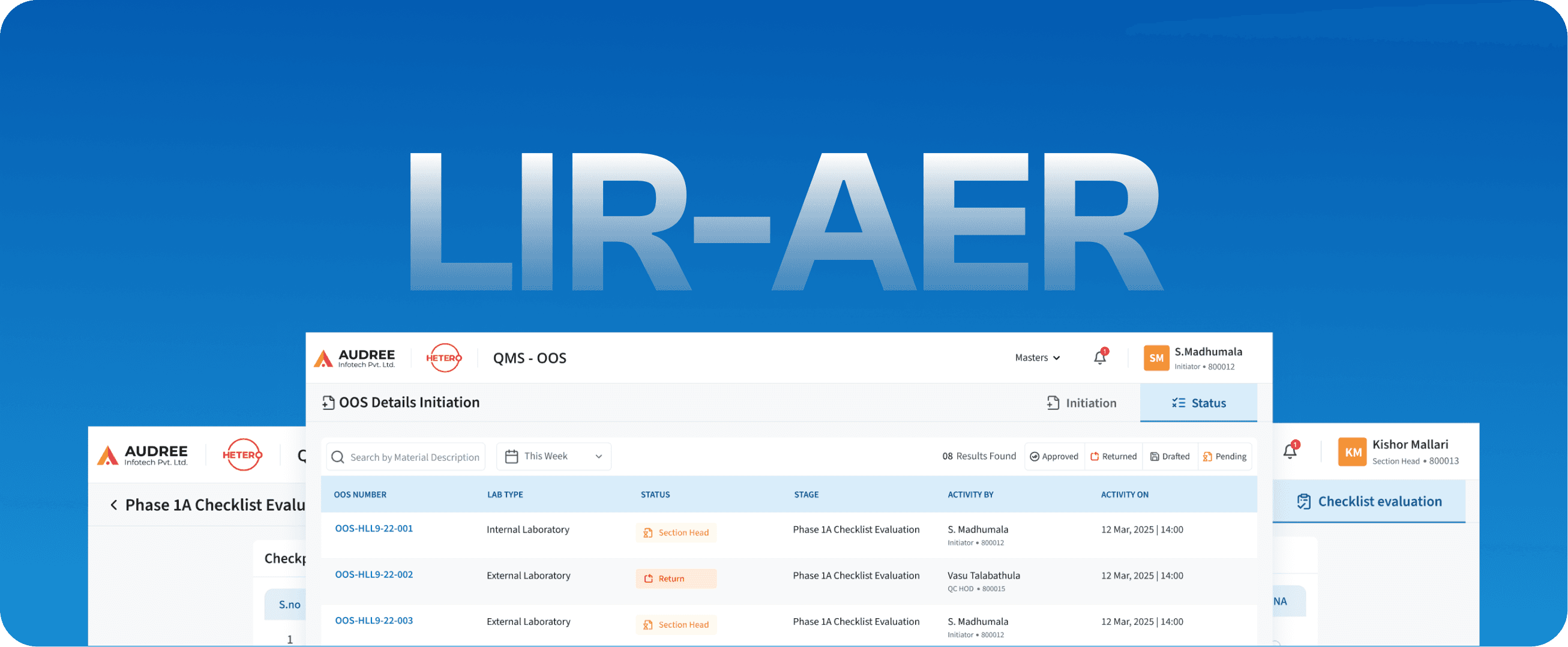

LIR-AER

Laboratory Information Record

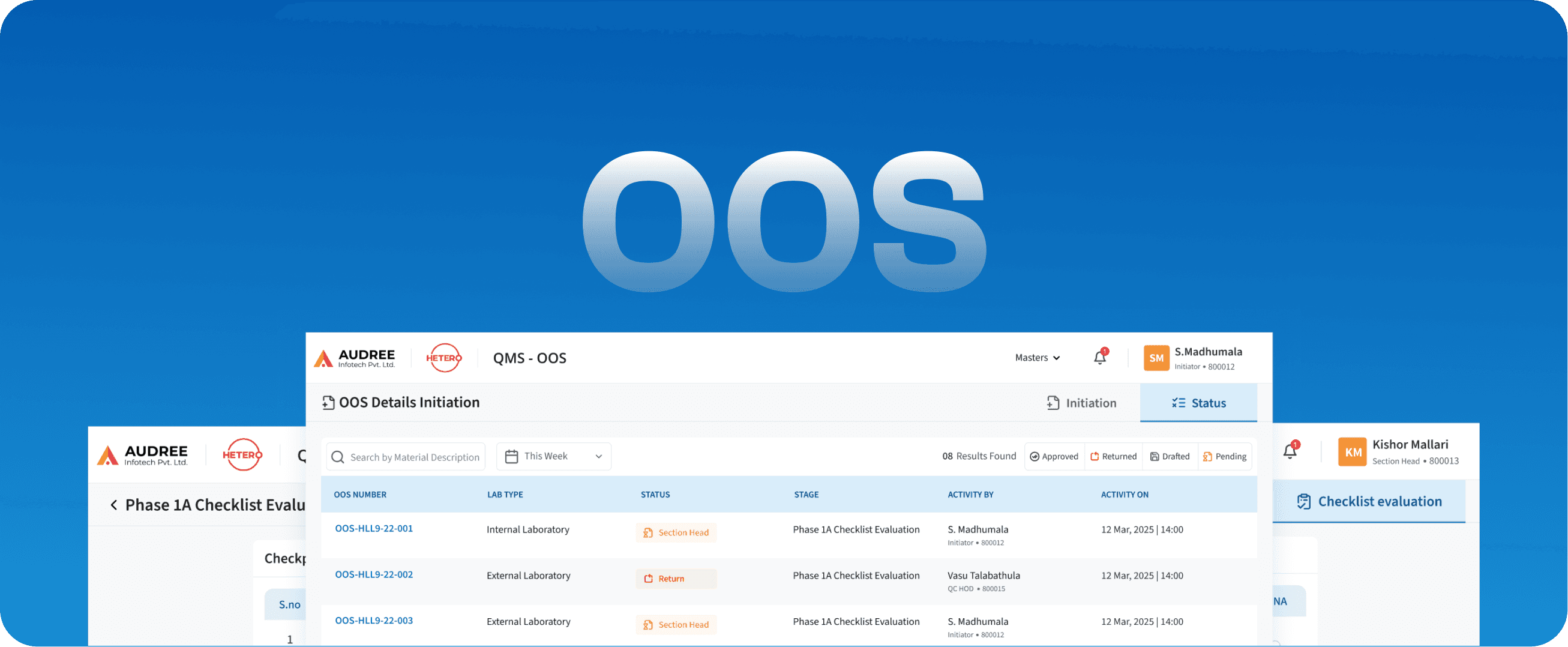

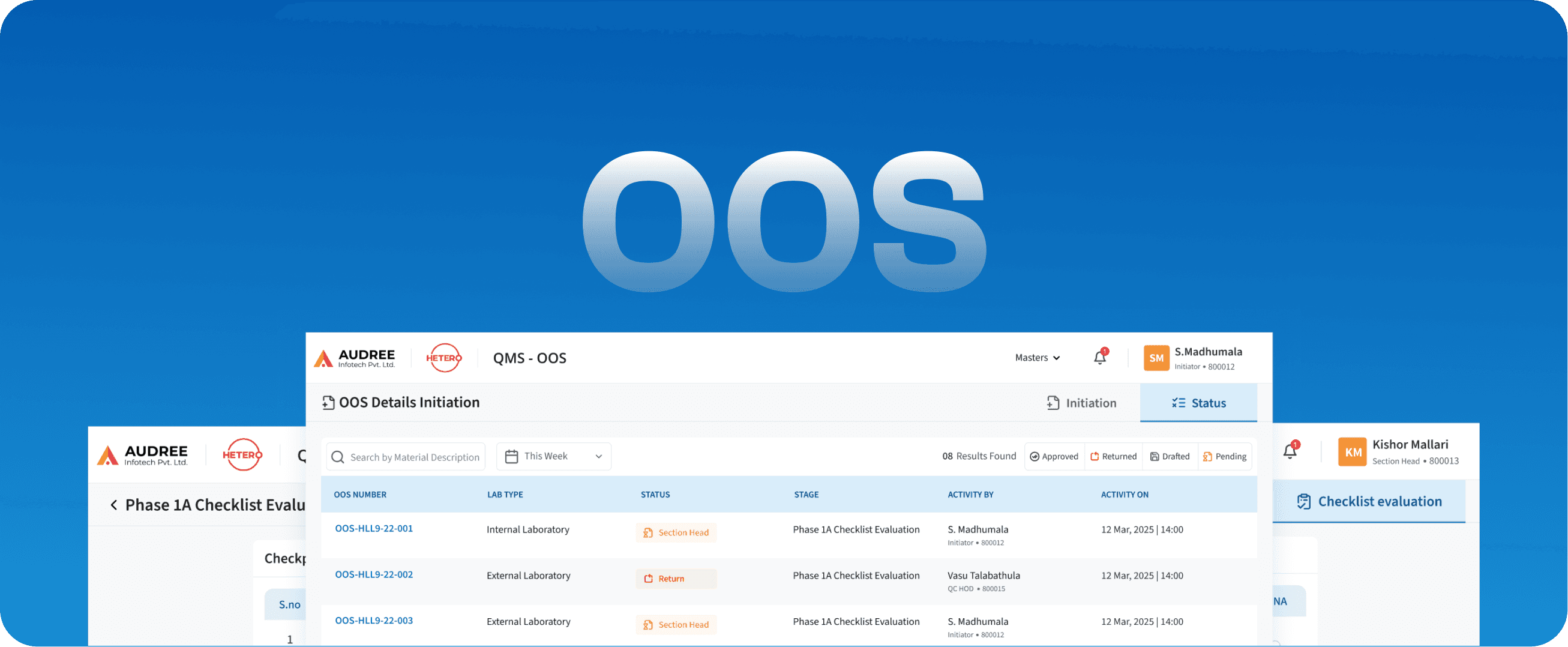

OOS

Out Of Specification

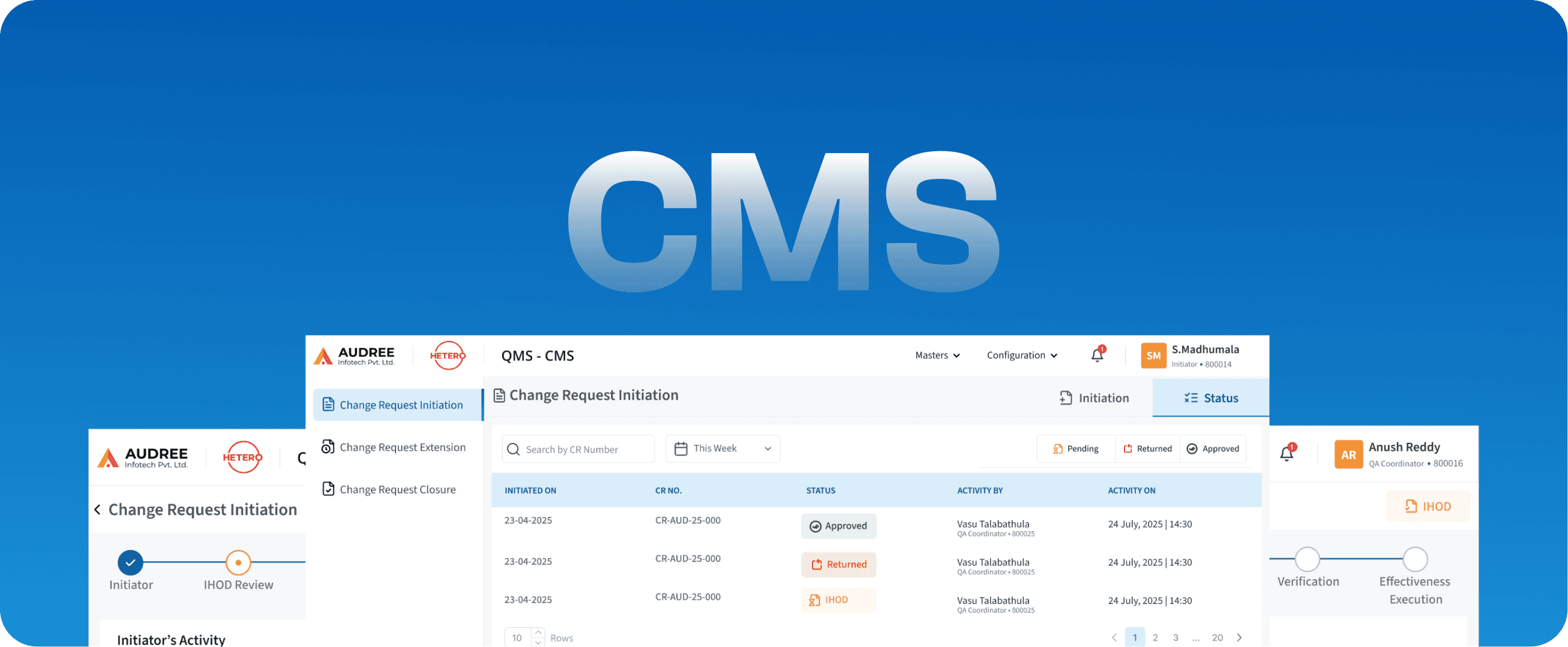

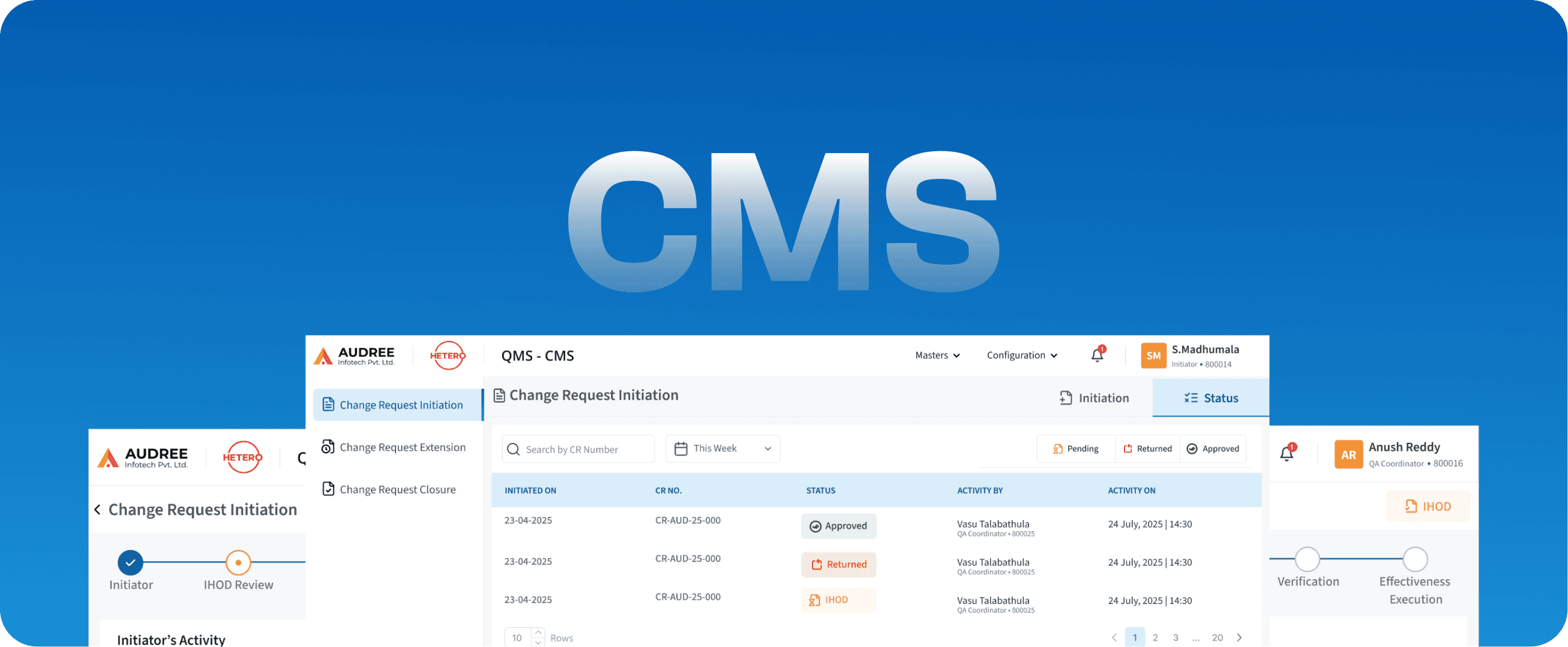

CMS

Change Management System

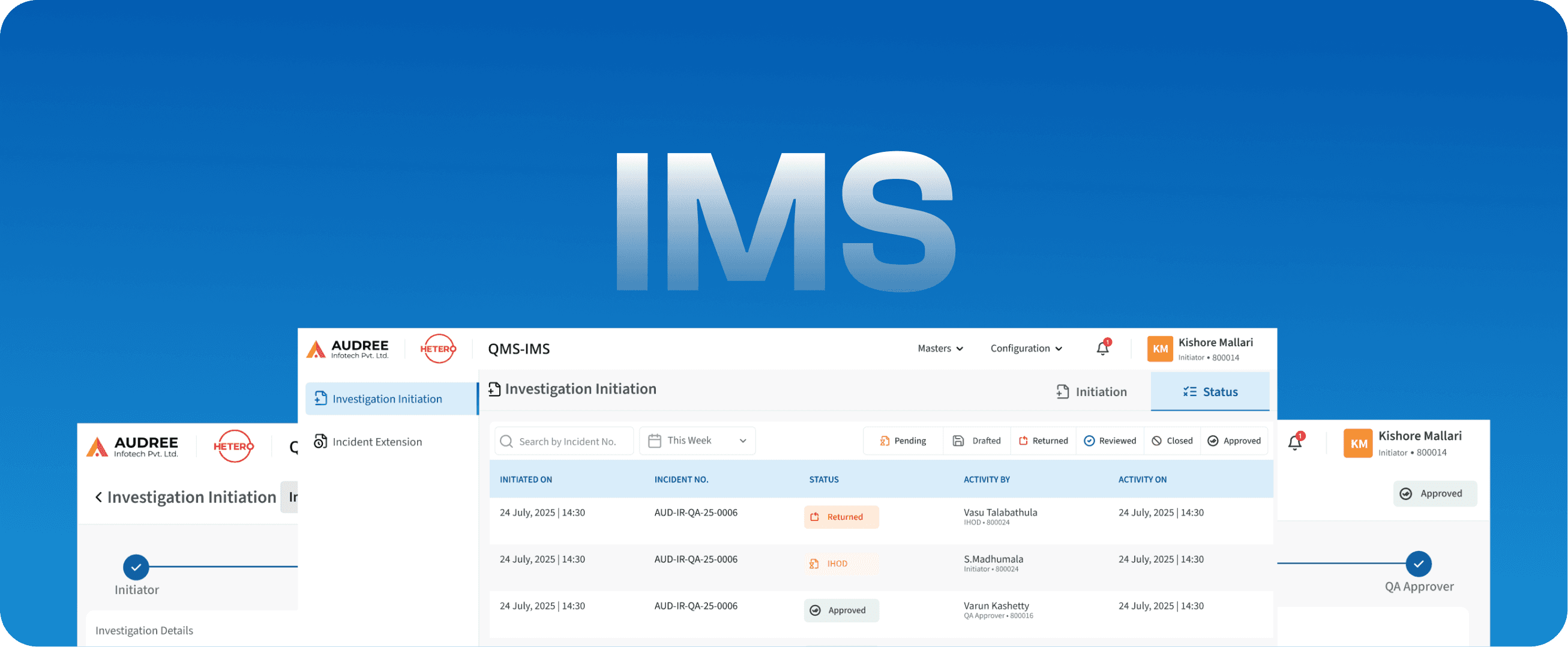

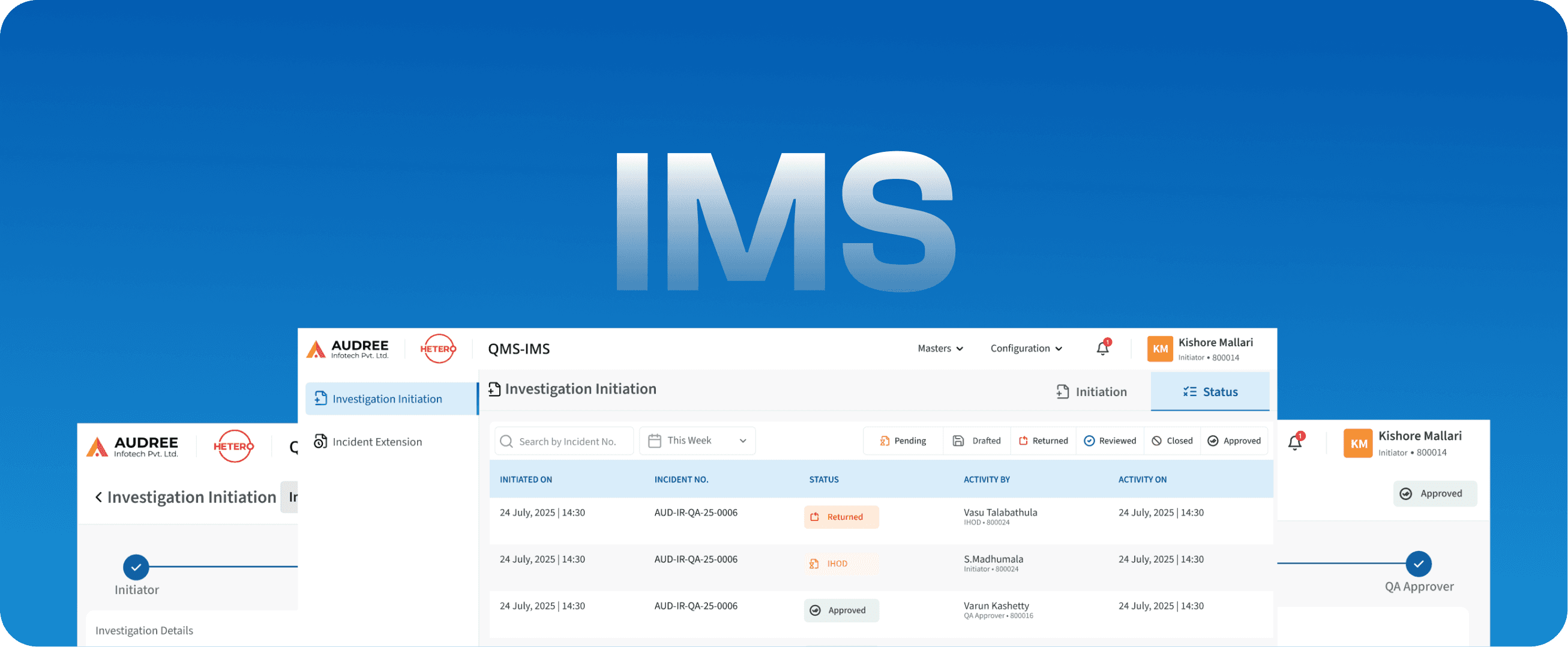

IMS

Incident Management System

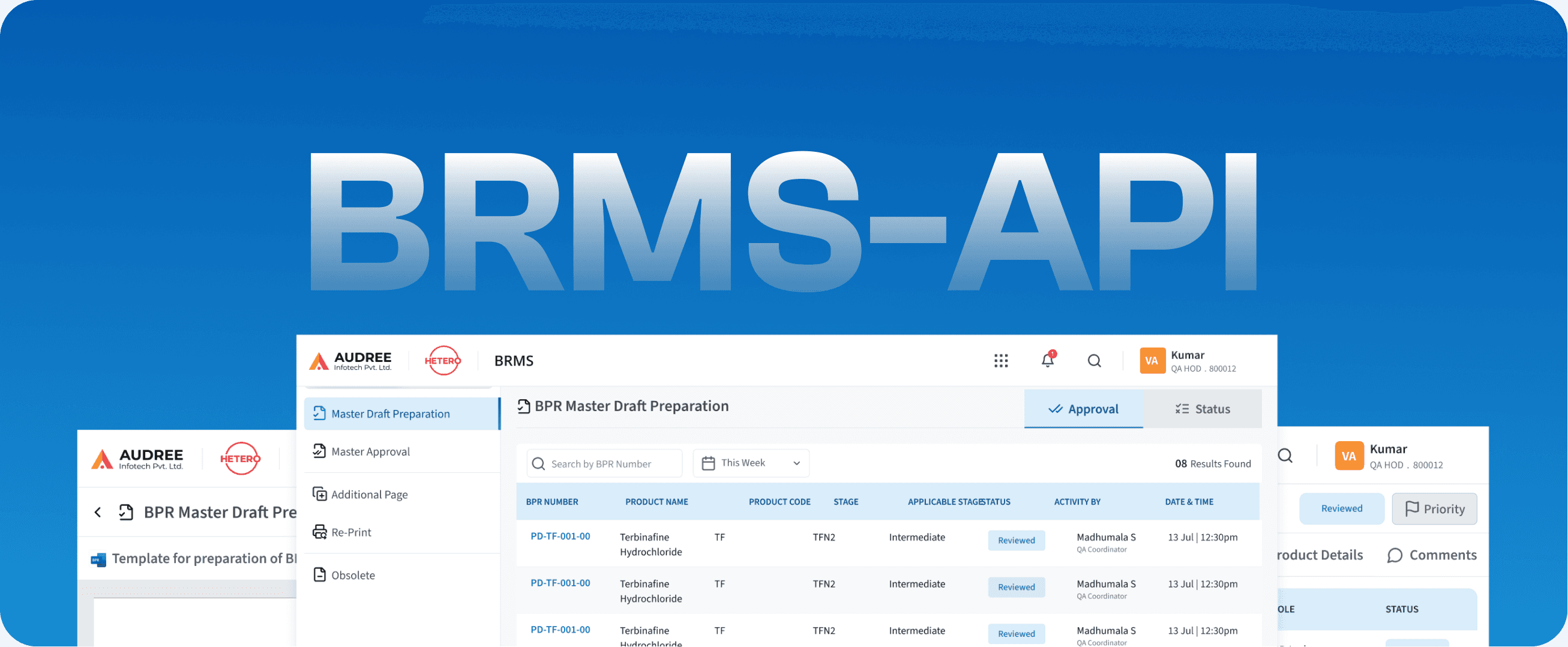

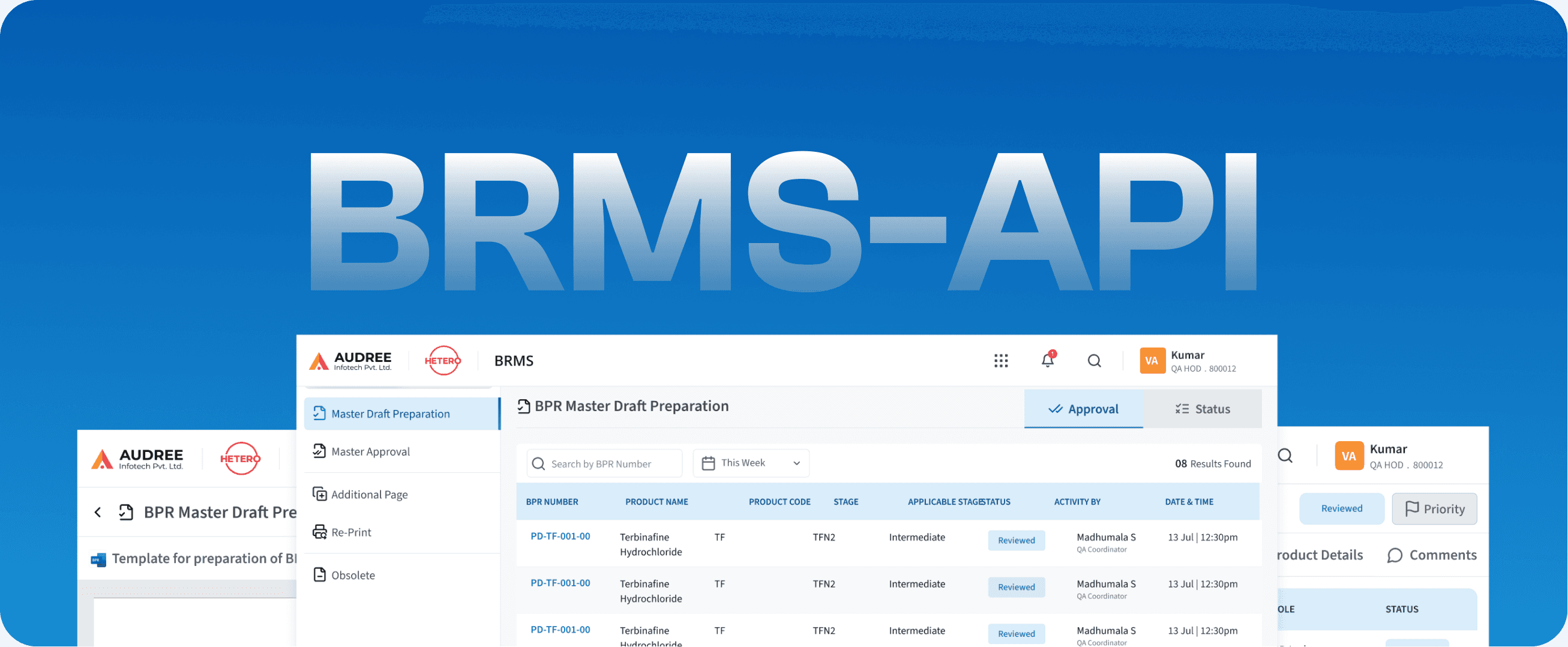

BRMS-API

Batch Record- Active Pharmaceutical Ingredient

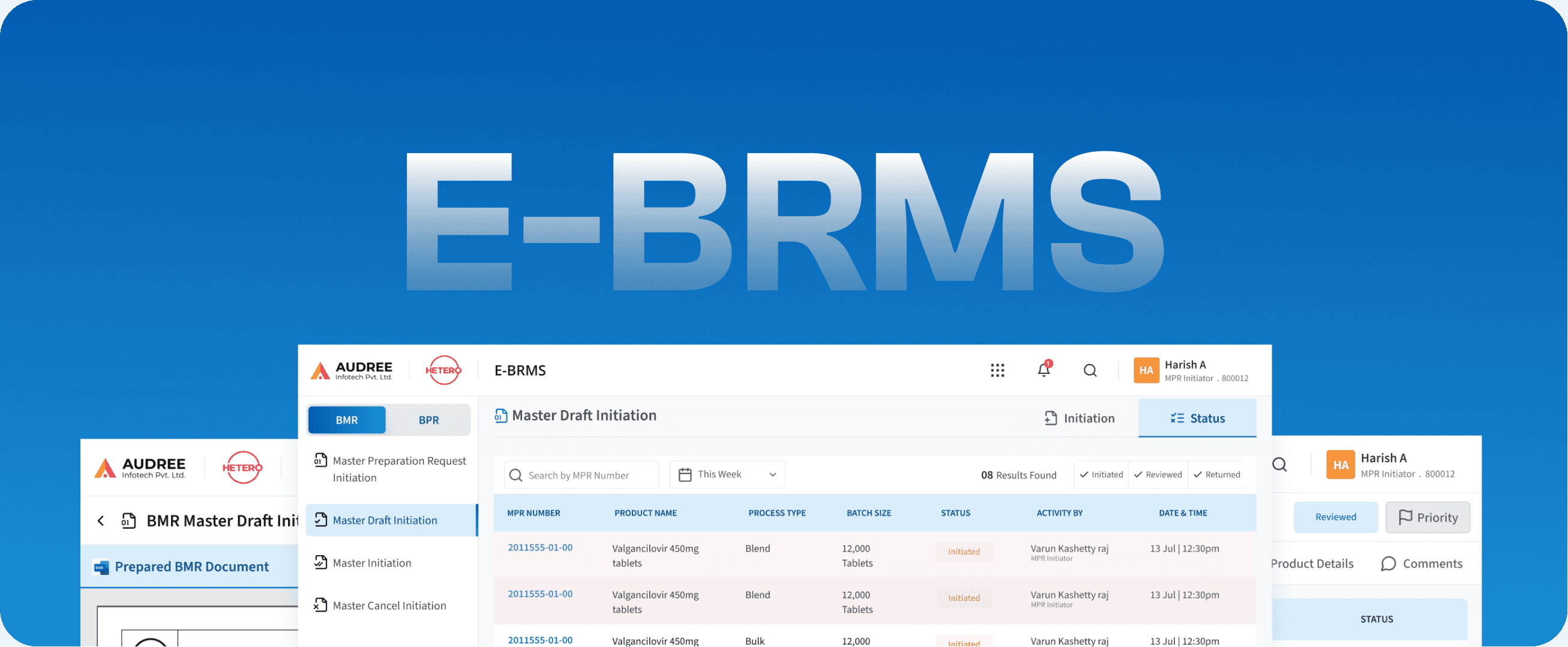

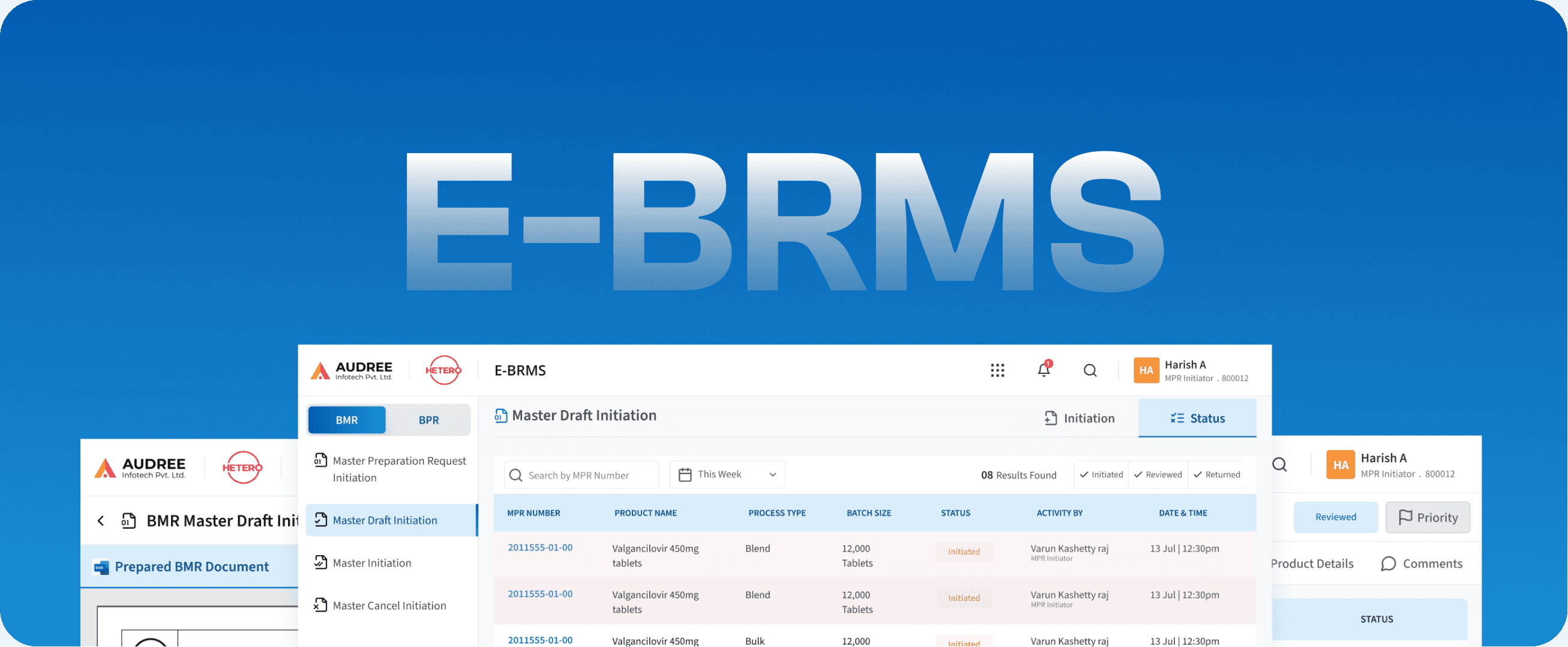

E-BRMS

Batch Record Management System

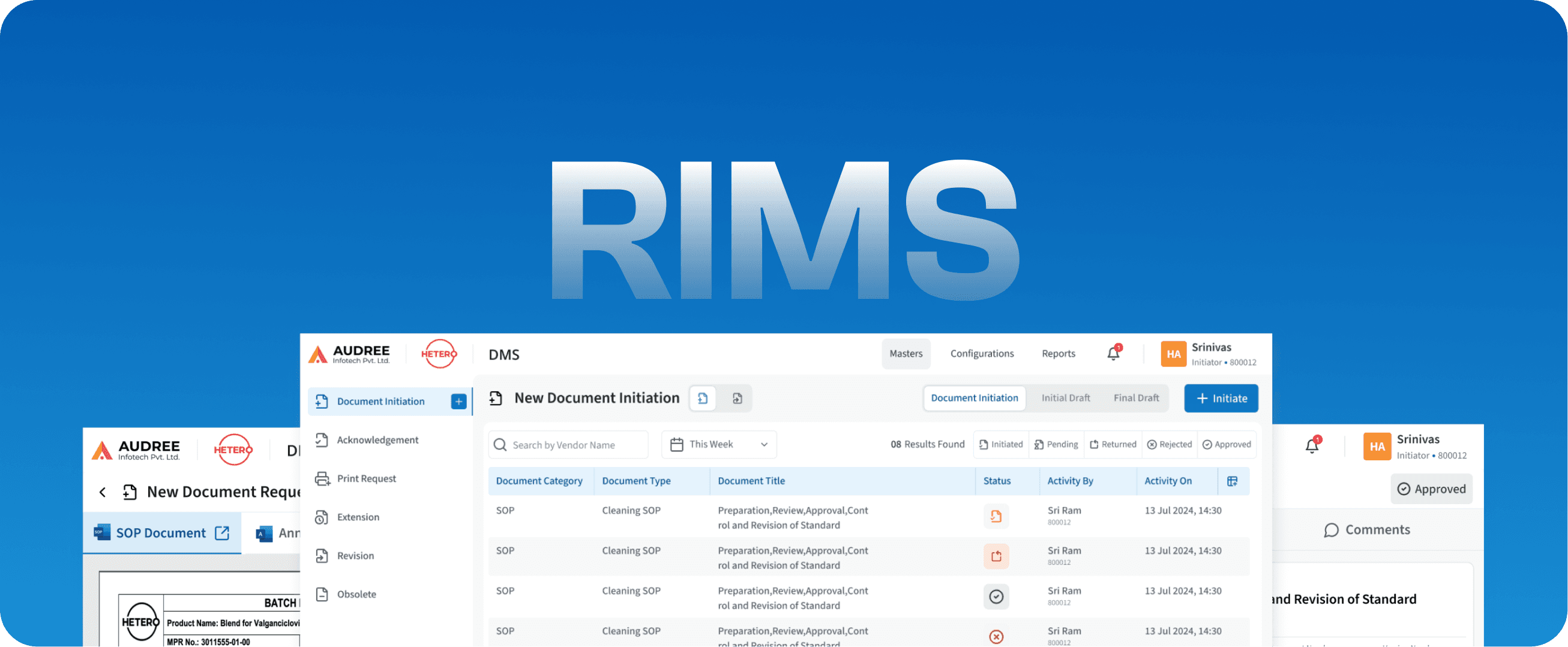

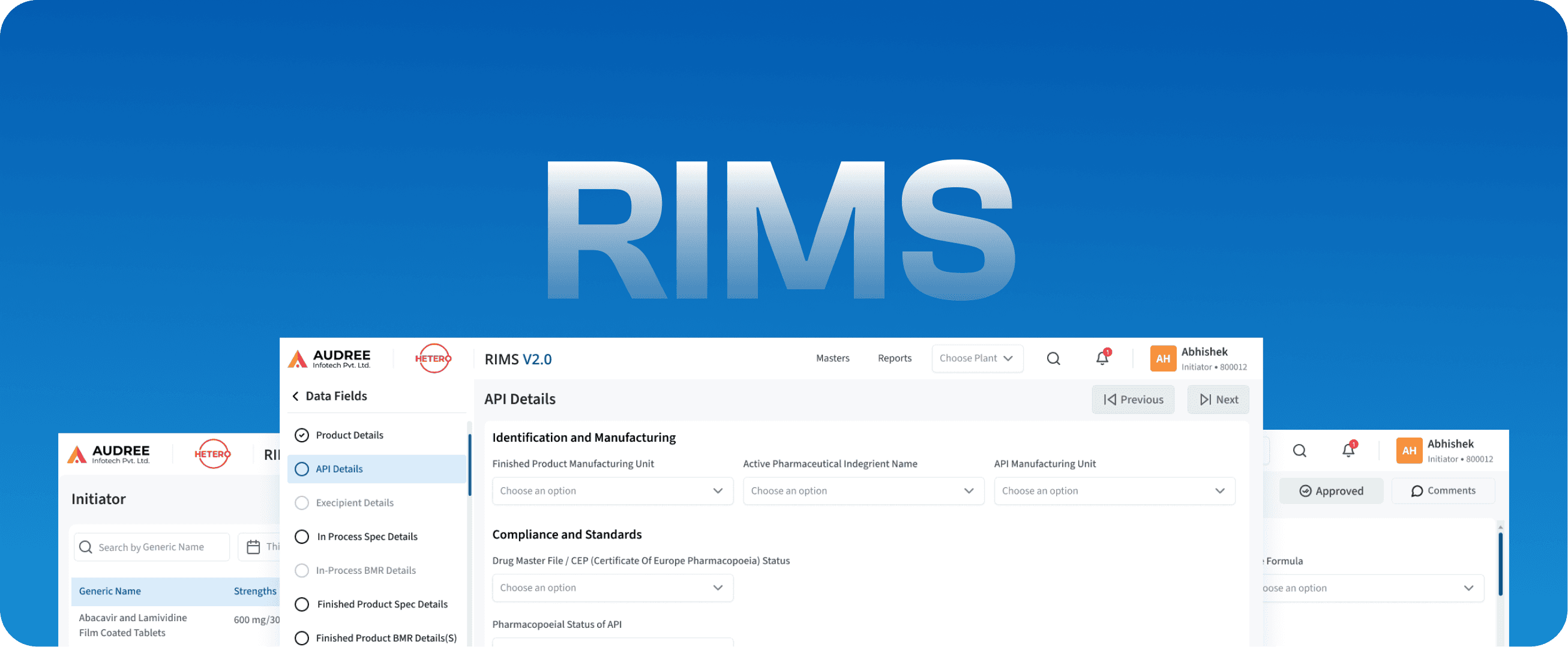

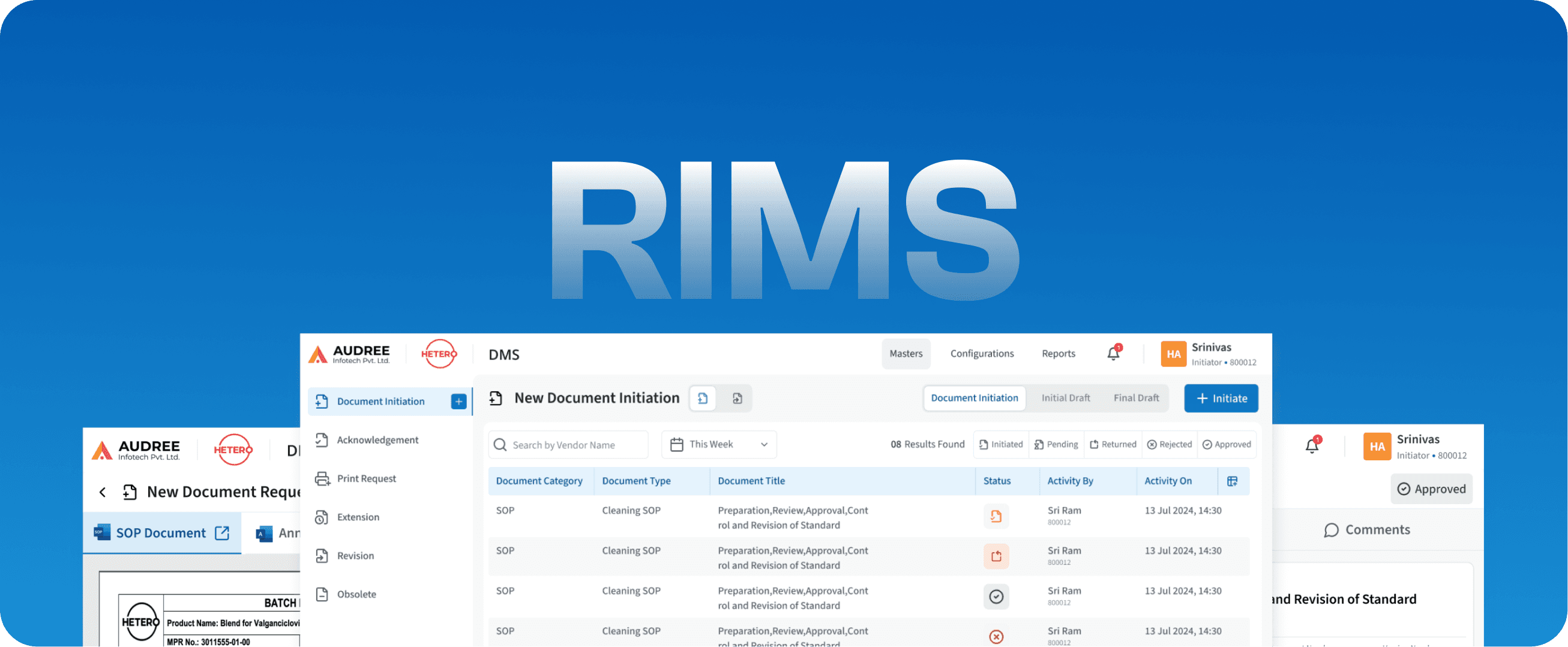

RIMS

Regulatory Information Management System

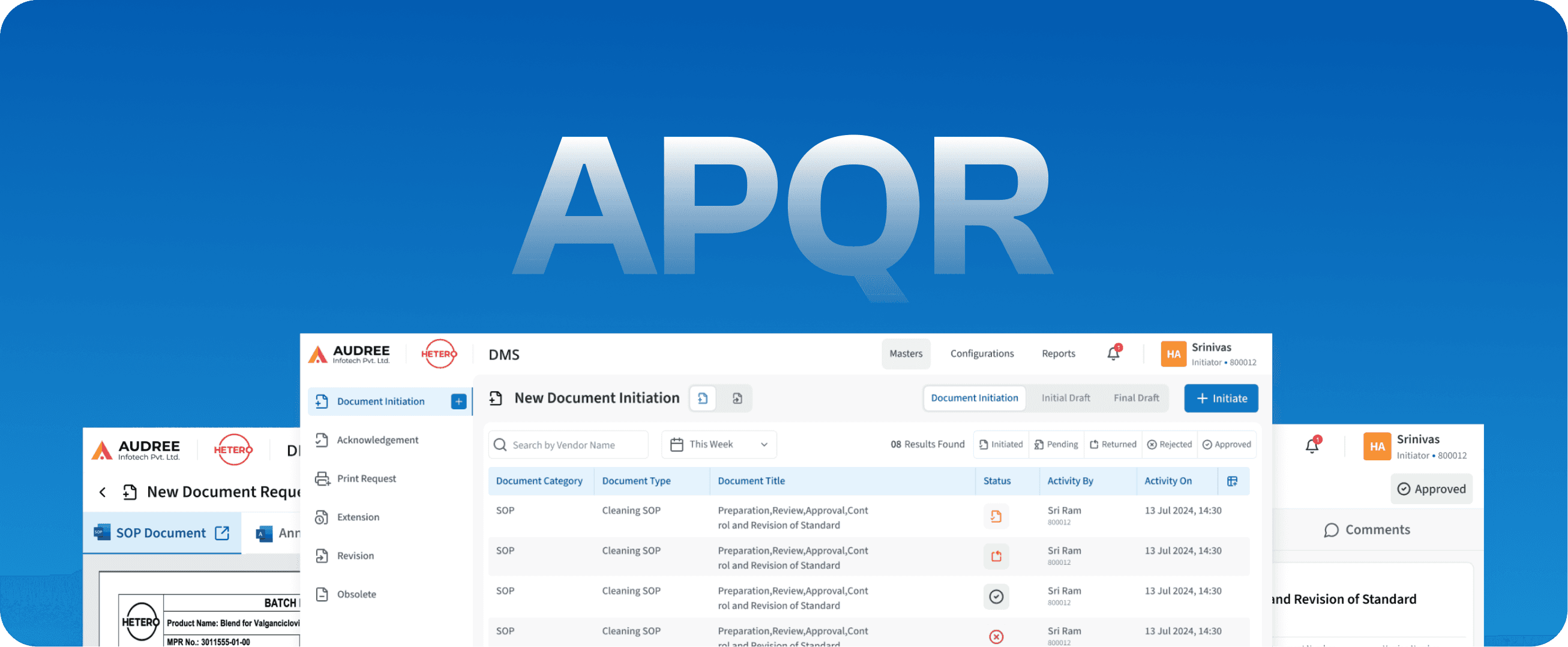

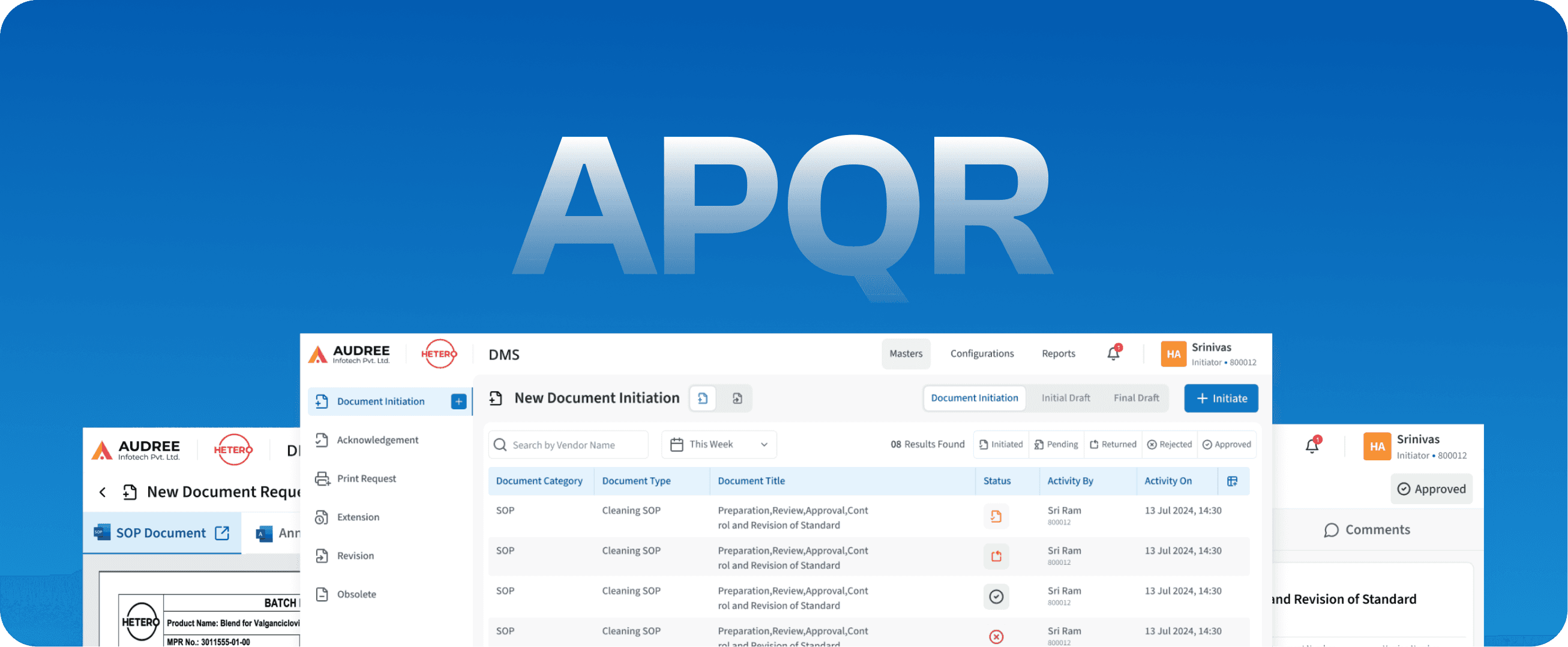

APQR

Annual Product Quality Review

RCAI

Root Cause Analysis with Intelligence

LMS

Learning Management System

LIMS

Laboratory Information Management System

S & OP

Sales & Operations Planning

E-BMR

Batch Manufacturing Recall

RIMS

Regulatory Information Management Systems

IMS

Incident Management System

BRMS-API

Batch Record- Active Pharmaceutical Ingredient

E-BRMS

Batch Record Management System

APQR

Annual Product Quality Review

RIMS

Regulatory Information Management System

WMPS

Warehouse Management System

DMS

Document Management System

CMS

Change Management System

OOS

Out Of Specification

LIR-AER

Laboratory Information Record

Vendor Portal

Vendor Management System

QAS

Quality Agreement System

CAPA

Corrective And Preventive Actions