Redefining Pharma Warehouse Operations with Intuitive UX Design

Redefining Pharma Warehouse Operations with Intuitive UX Design

Redefining Pharma Warehouse Operations with Intuitive UX Design

About Project

About Project

About Project

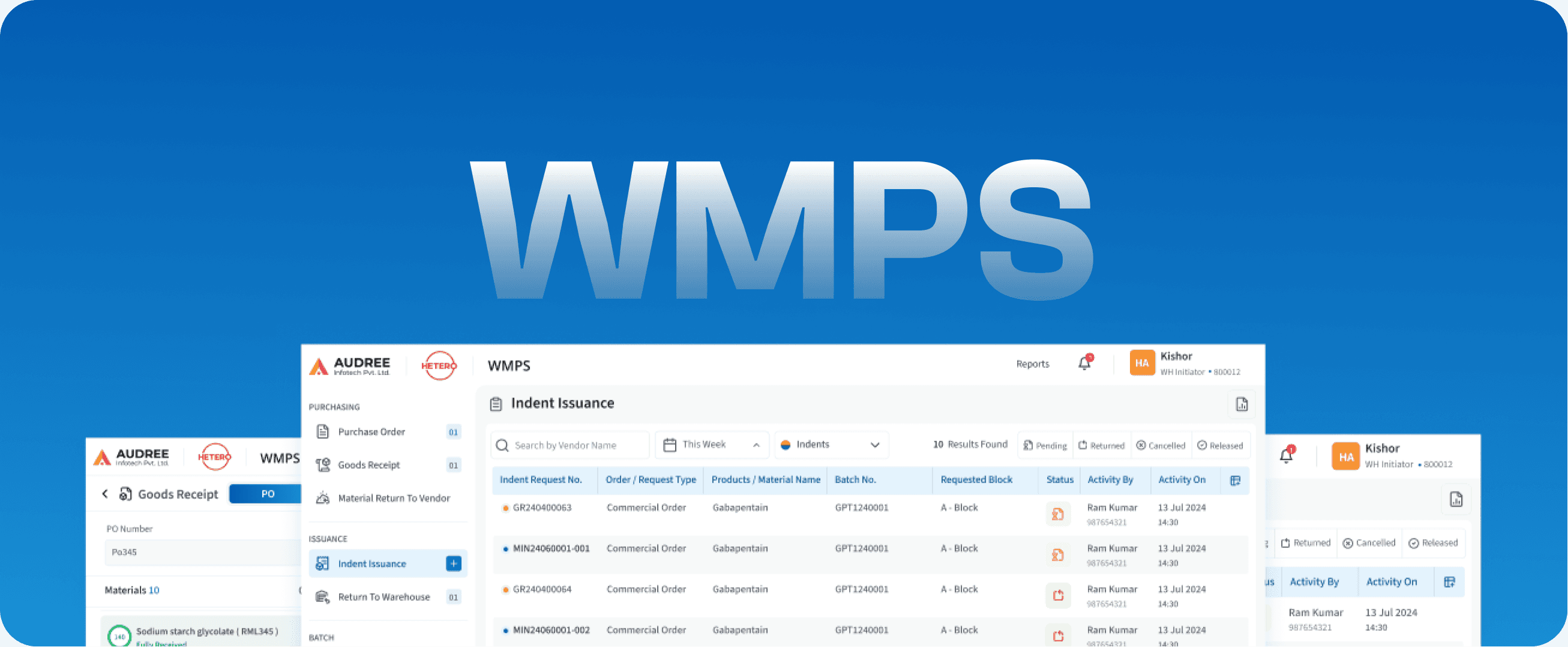

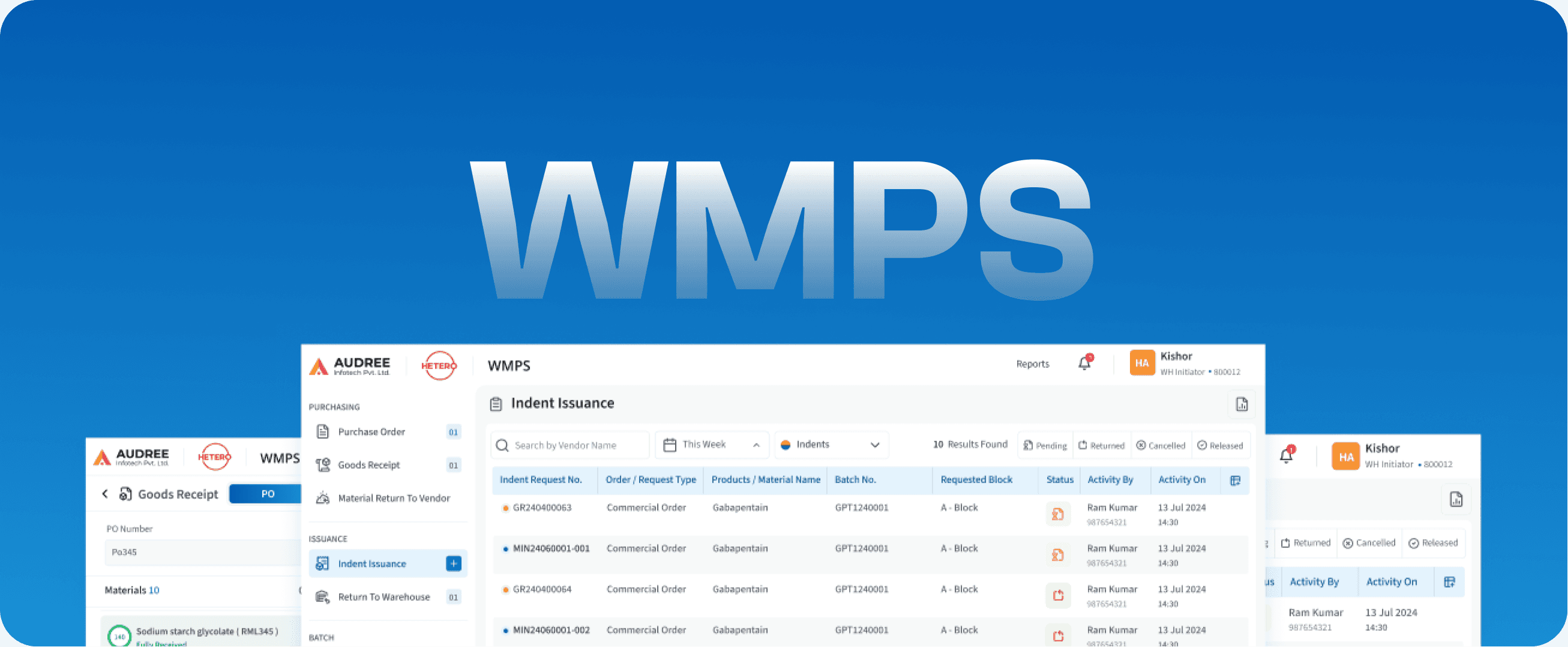

WMPS (Warehouse Management and Planning System) is a specialized pharmaceutical software designed to manage material movement, storage, and inventory operations within manufacturing facilities.

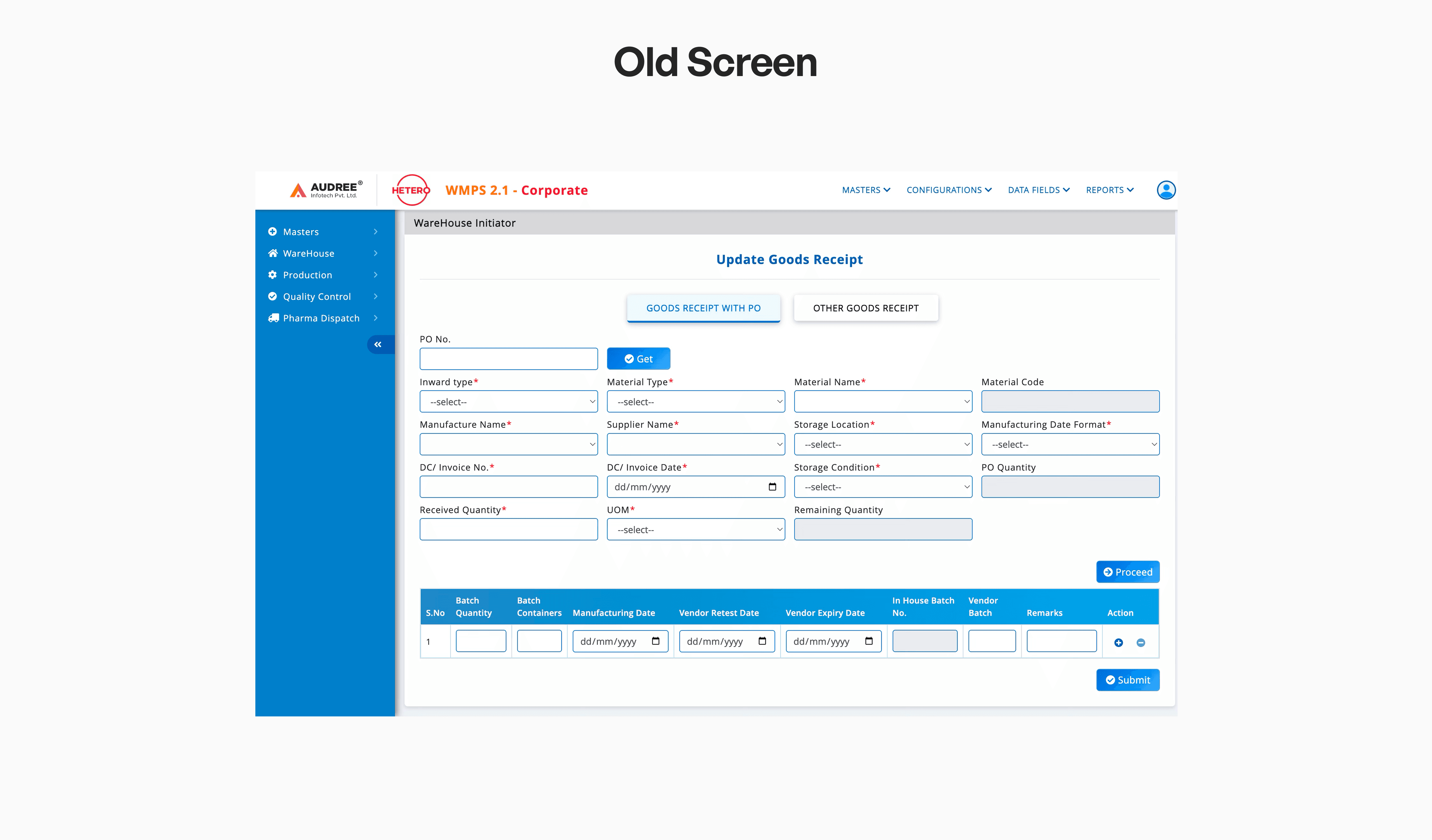

WMPS had become difficult to use due to outdated design, confusing workflows, and limited traceability. Scattered data and frequent manual updates slowed warehouse operations, causing inefficiencies and stock inaccuracies.

Our goal was to simplify WMPS workflows and enhance visibility, usability, and accuracy across warehouse operations from material receipt to dispatch. The redesign improved navigation, reduced manual effort, and gave teams better control over stock and efficiency.

WMPS (Warehouse Management and Planning System) is a specialized pharmaceutical software designed to manage material movement, storage, and inventory operations within manufacturing facilities.

WMPS had become difficult to use due to outdated design, confusing workflows, and limited traceability. Scattered data and frequent manual updates slowed warehouse operations, causing inefficiencies and stock inaccuracies.

Our goal was to simplify WMPS workflows and enhance visibility, usability, and accuracy across warehouse operations from material receipt to dispatch. The redesign improved navigation, reduced manual effort, and gave teams better control over stock and efficiency.

About Project

Pharmaceutical

Team

Anush Reddy, S.Madhumala

Subscription Category

Quick win

Project start Year

August 2024

Core Business Challenges

Core Business Challenges

Core Business Challenges

Poor User Adoption Due to Outdated Experience

Poor User Adoption Due to Outdated Experience

Poor User Adoption Due to Outdated Experience

The outdated interface and confusing layouts made simple tasks hard, forcing users to depend on support and trainingreducing productivity and engagement.

The outdated interface and confusing layouts made simple tasks hard, forcing users to depend on support and trainingreducing productivity and engagement.

The outdated interface and confusing layouts made simple tasks hard, forcing users to depend on support and trainingreducing productivity and engagement.

Stuck in a Loop, Slowed by Inefficiency

Stuck in a Loop, Slowed by Inefficiency

Stuck in a Loop, Slowed by Inefficiency

Manual updates, inconsistent data, and repetitive workflows kept warehouse teams busy fixing the same issues slowing operations and limiting scalability.

Manual updates, inconsistent data, and repetitive workflows kept warehouse teams busy fixing the same issues slowing operations and limiting scalability.

Manual updates, inconsistent data, and repetitive workflows kept warehouse teams busy fixing the same issues slowing operations and limiting scalability.

Heavy Dependence on Manual Coordination

Heavy Dependence on Manual Coordination

Material tracking and approvals depended on offline communication and spreadsheets, leading to data mismatches, delays, and frequent errors.

Material tracking and approvals depended on offline communication and spreadsheets, leading to data mismatches, delays, and frequent errors.

Heavy Dependence on Manual Coordination

Material tracking and approvals depended on offline communication and spreadsheets, leading to data mismatches, delays, and frequent errors.

Our Approach

Our Approach

Our Approach

Mapping User Flows to Uncover Hidden Gaps

We mapped every stage of warehouse operations from material receipt and storage to dispatch and planning to identify redundant steps and process gaps. These visual flows helped simplify navigation and reduce task time for warehouse teams.

Mapping User Flows to Uncover Hidden Gaps

We mapped every stage of warehouse operations from material receipt and storage to dispatch and planning to identify redundant steps and process gaps. These visual flows helped simplify navigation and reduce task time for warehouse teams.

Mapping User Flows to Uncover Hidden Gaps

We mapped every stage of warehouse operations from material receipt and storage to dispatch and planning to identify redundant steps and process gaps. These visual flows helped simplify navigation and reduce task time for warehouse teams.

Streamlining Every Step From Indent to Dispatch

Streamlining Every Step From Indent to Dispatch

Streamlining Every Step From Indent to Dispatch

We mapped and simplified the entire material journey from indent and production to warehouse storage, quality assessment, and final dispatch. Each stage was restructured for traceability, faster actions, and reduced back-and-forth. Clear status tags, guided transitions, and unified layouts now give users a complete view of stock movement, improving accuracy across departments.

We mapped and simplified the entire material journey from indent and production to warehouse storage, quality assessment, and final dispatch. Each stage was restructured for traceability, faster actions, and reduced back-and-forth. Clear status tags, guided transitions, and unified layouts now give users a complete view of stock movement, improving accuracy across departments.

Simplified Data Access For Warehouse Teams Across All Roles

Simplified Data Access For Warehouse Teams Across All Roles

Simplified Data Access For Warehouse Teams Across All Roles

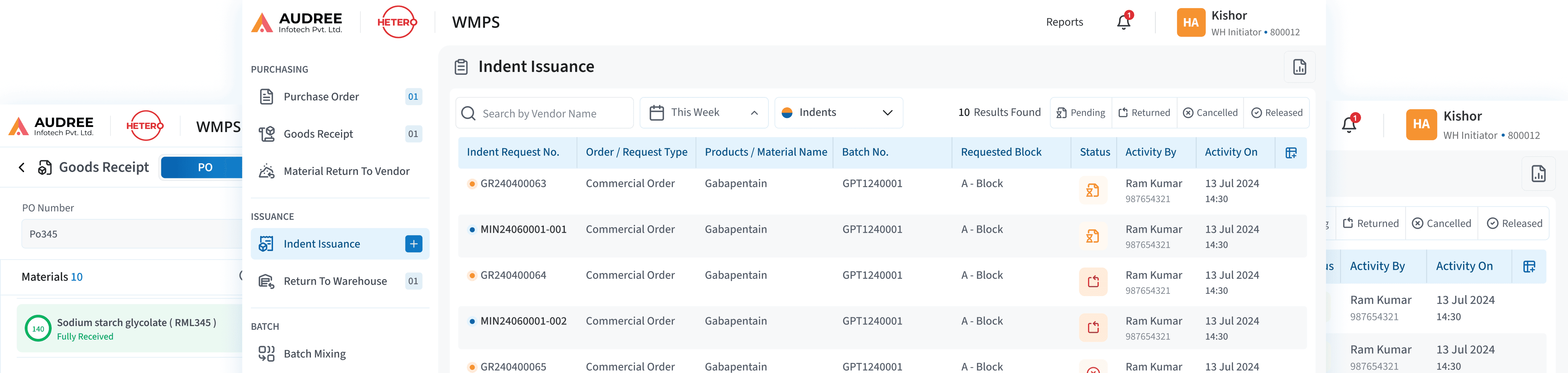

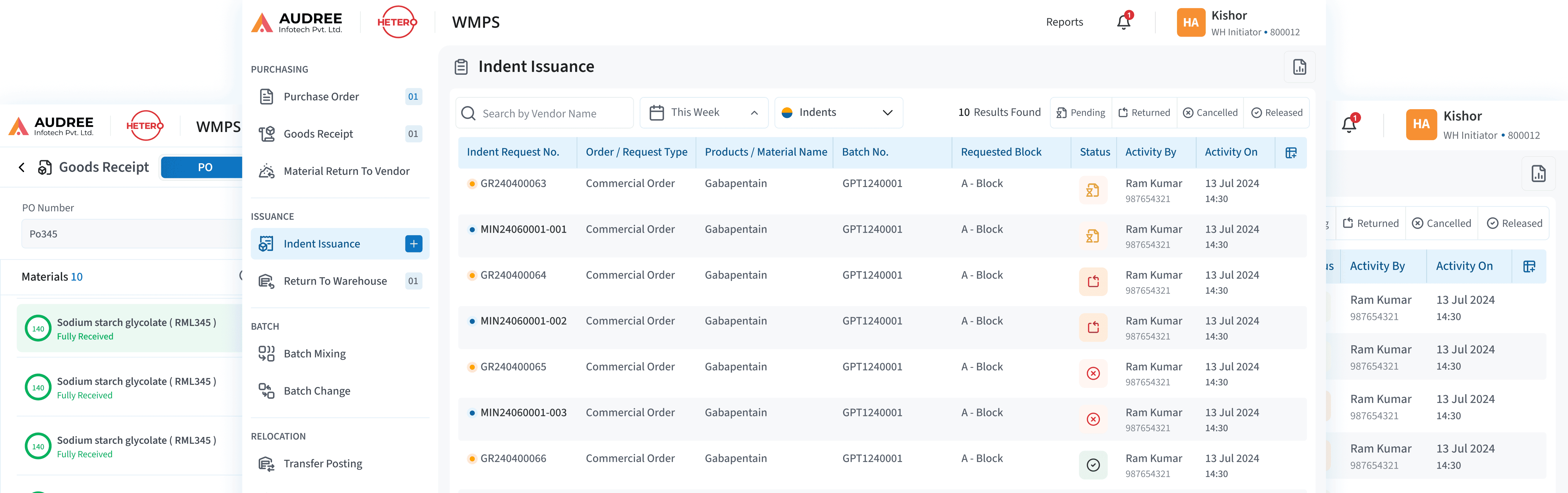

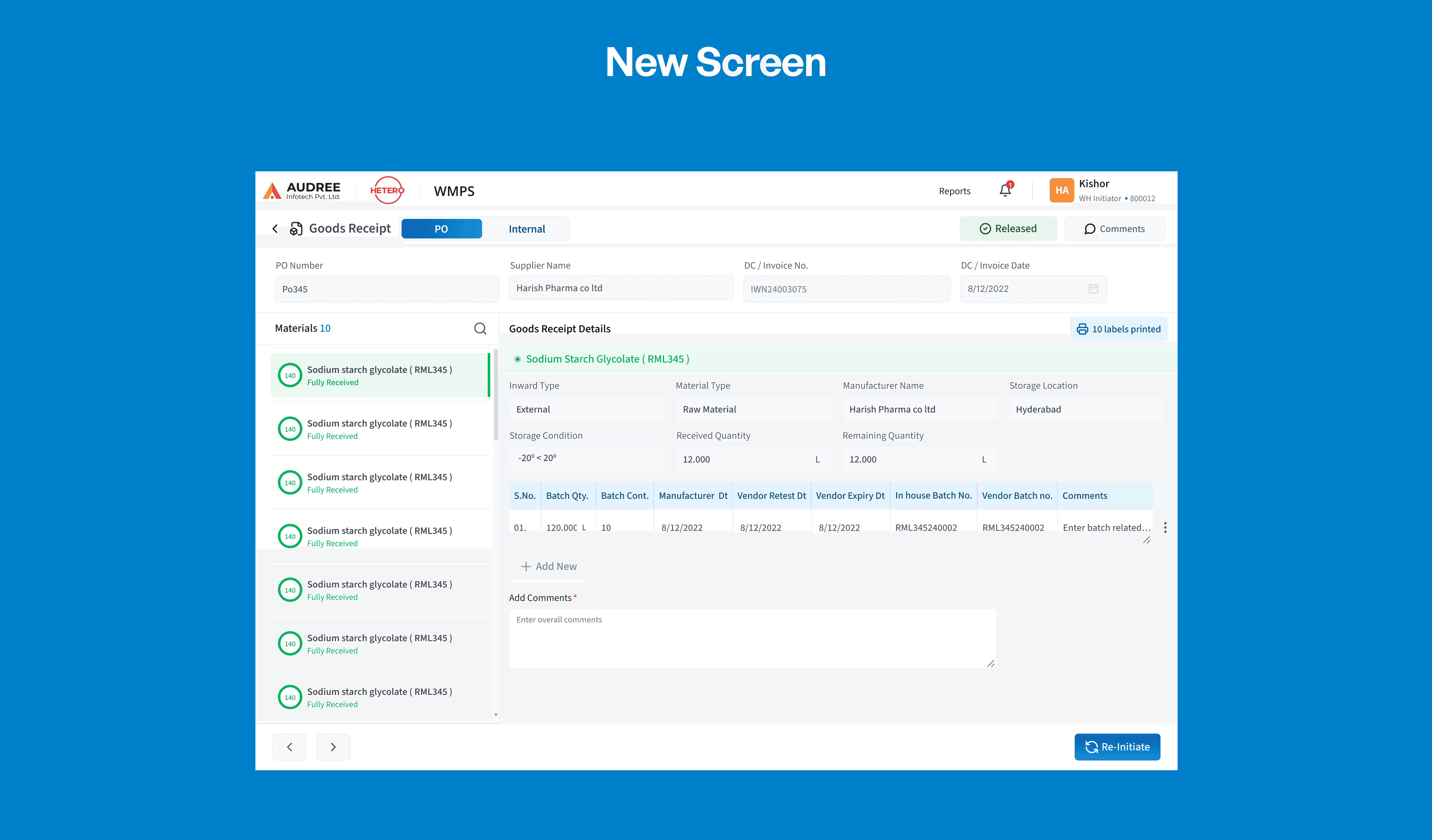

From Confusion to Clear Material Flow

From Confusion to Clear Material Flow

From Confusion to Clear Material Flow

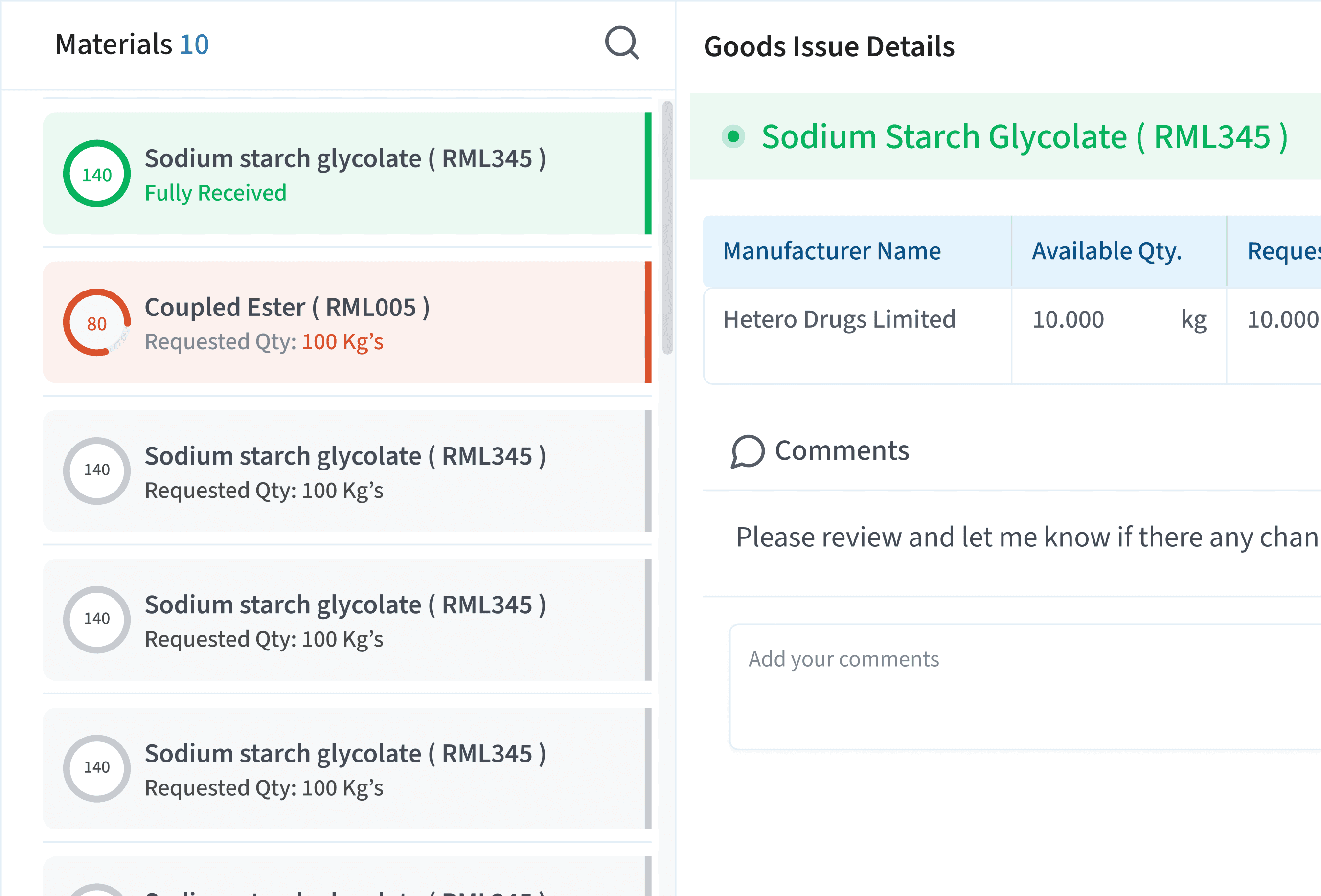

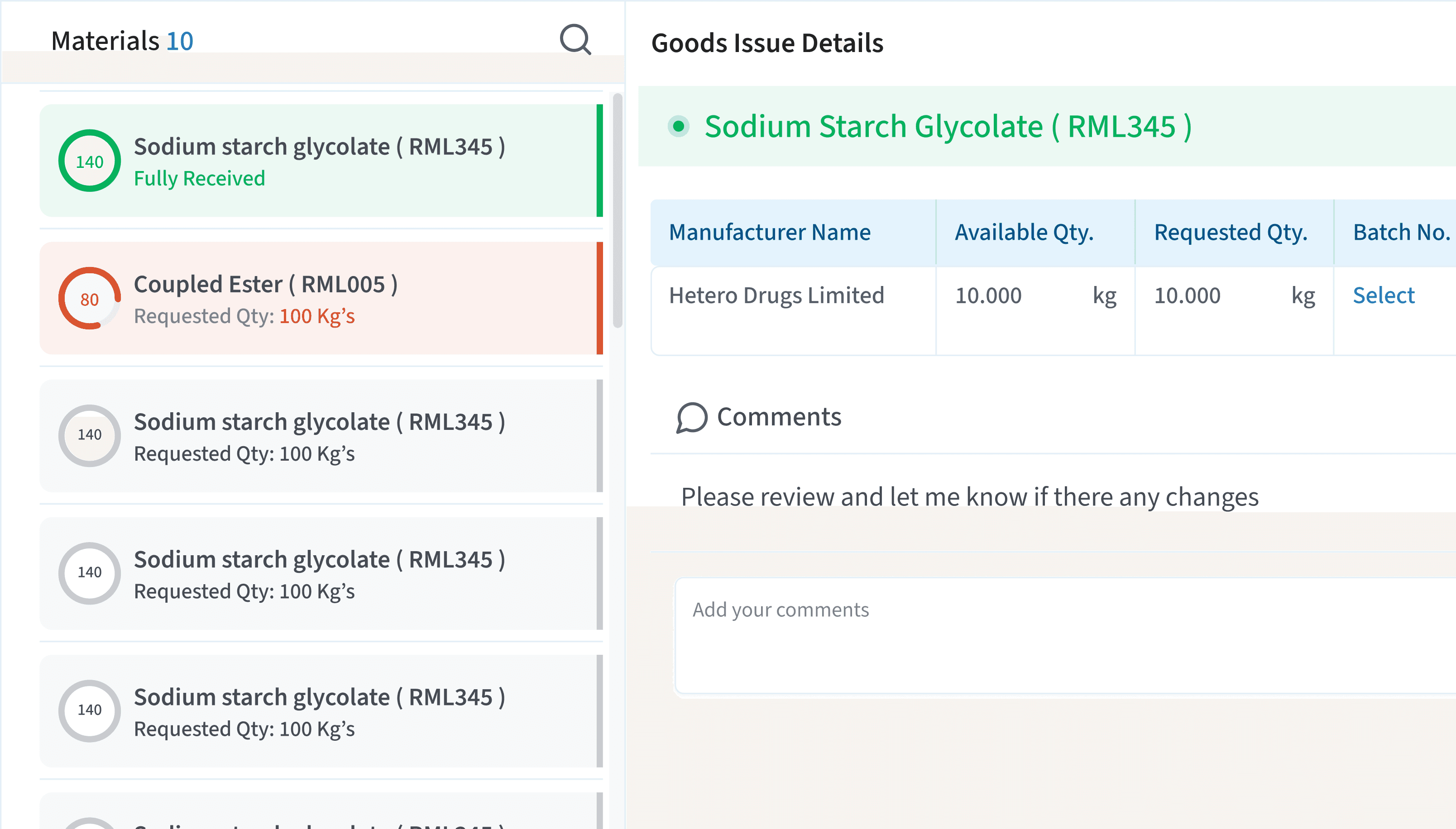

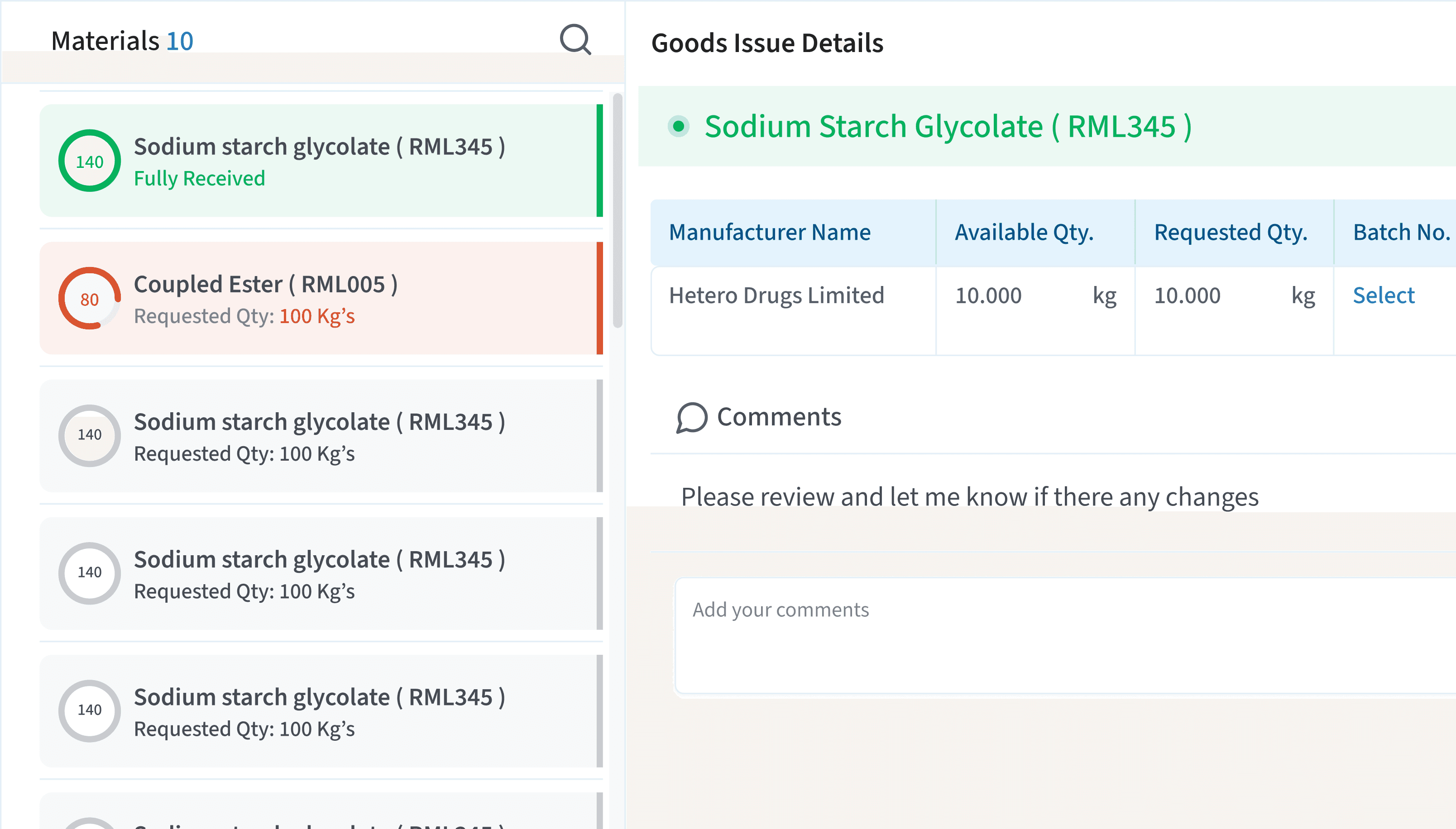

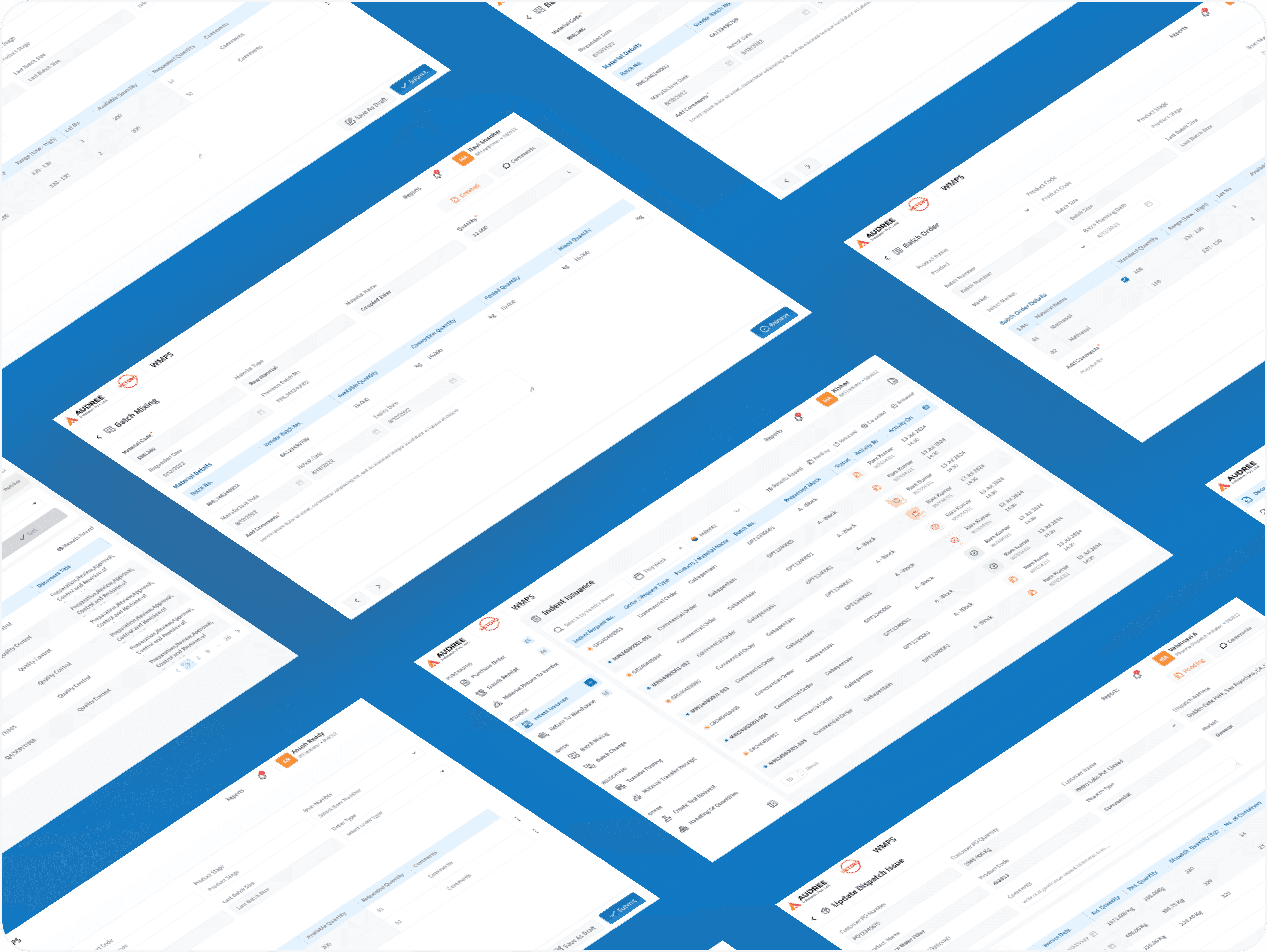

Goods Issue details are now visual, structured, and easy to scan replacing the old text-heavy tables where quantities and statuses were hard to spot.Each role can clearly see

Color-coded indicators

Progress rings

Clean material cards make received vs. pending quantities instantly clear

Side-by-side receipt and issue details

Teams get an accurate picture of material movement in seconds.

Goods Issue details are now visual, structured, and easy to scan replacing the old text-heavy tables where quantities and statuses were hard to spot.Each role can clearly see

Color-coded indicators

Progress rings

Clean material cards make received vs. pending quantities instantly clear

Side-by-side receipt and issue details

Teams get an accurate picture of material movement in seconds.

Goods Issue details are now visual, structured, and easy to scan replacing the old text-heavy tables where quantities and statuses were hard to spot.Each role can clearly see

Color-coded indicators

Progress rings

Clean material cards make received vs. pending quantities instantly clear

Side-by-side receipt and issue details

Teams get an accurate picture of material movement in seconds.

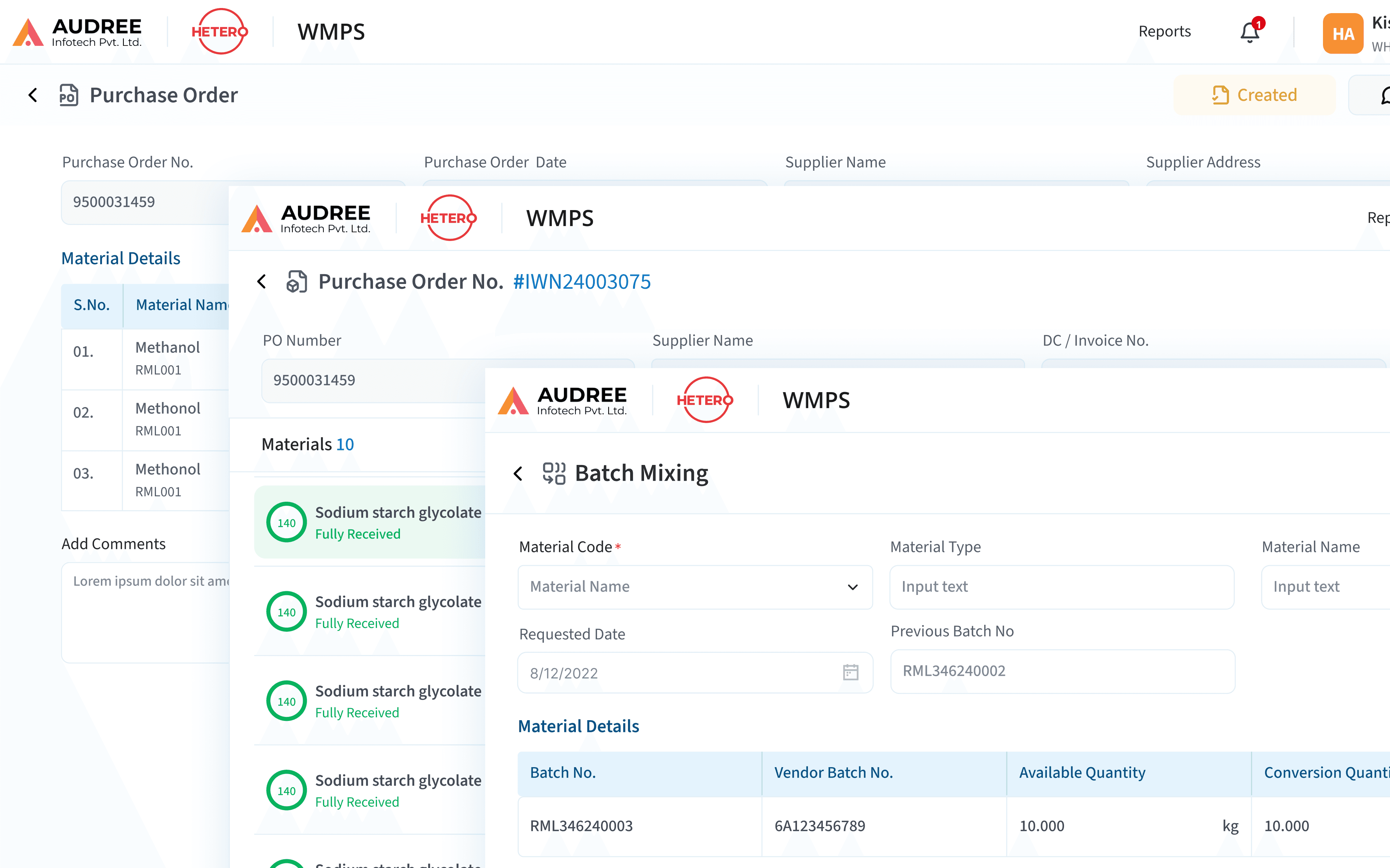

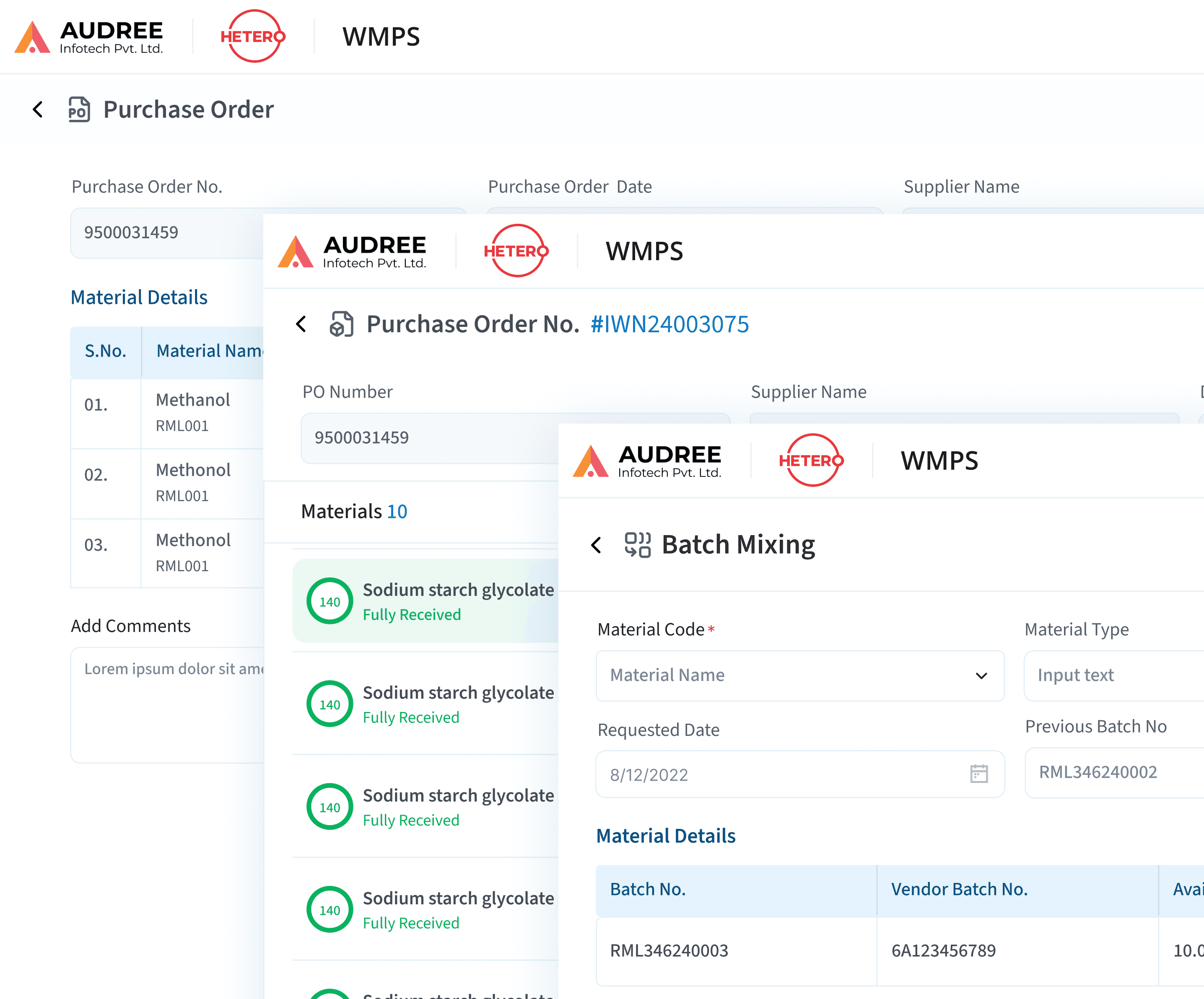

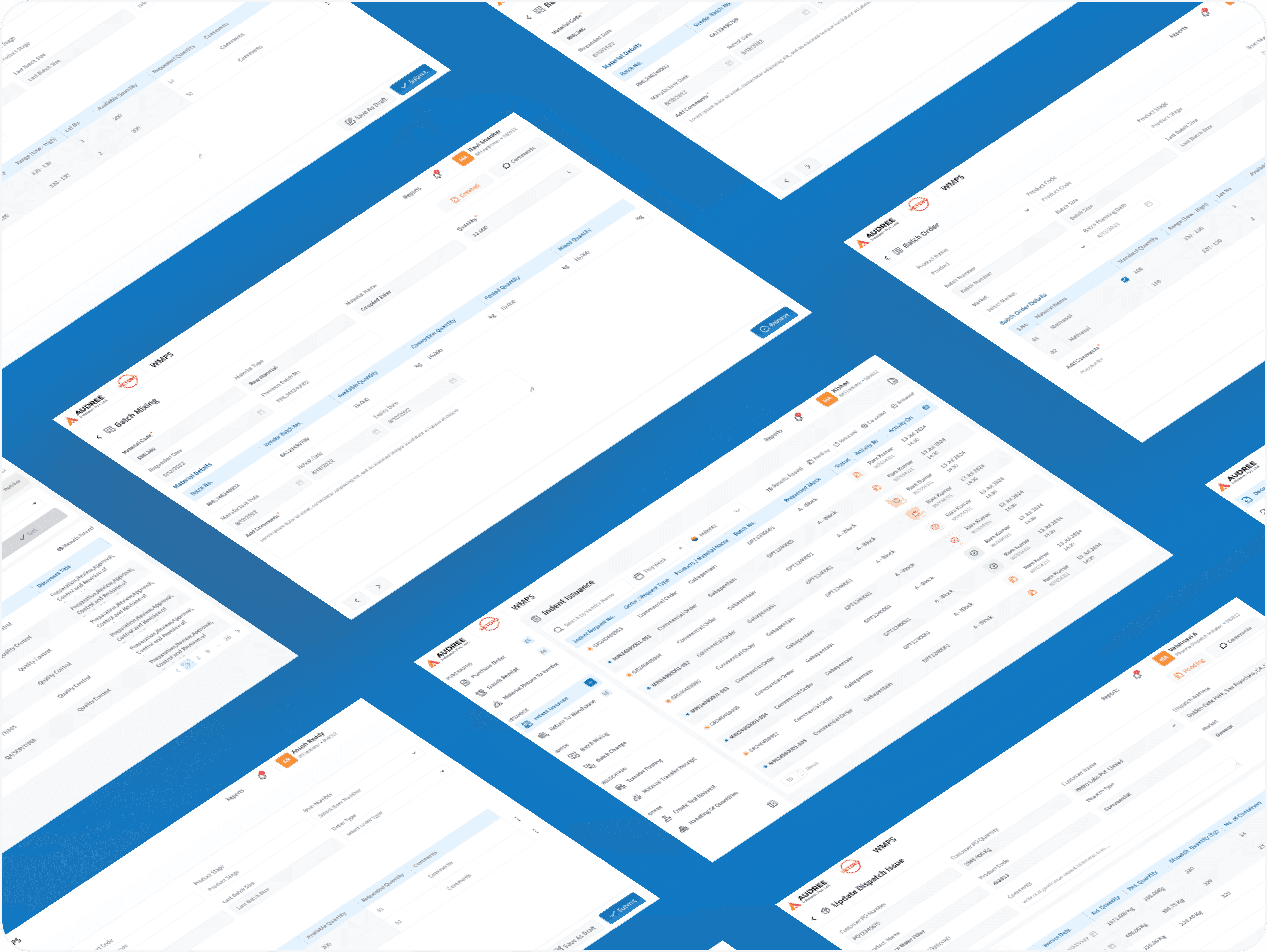

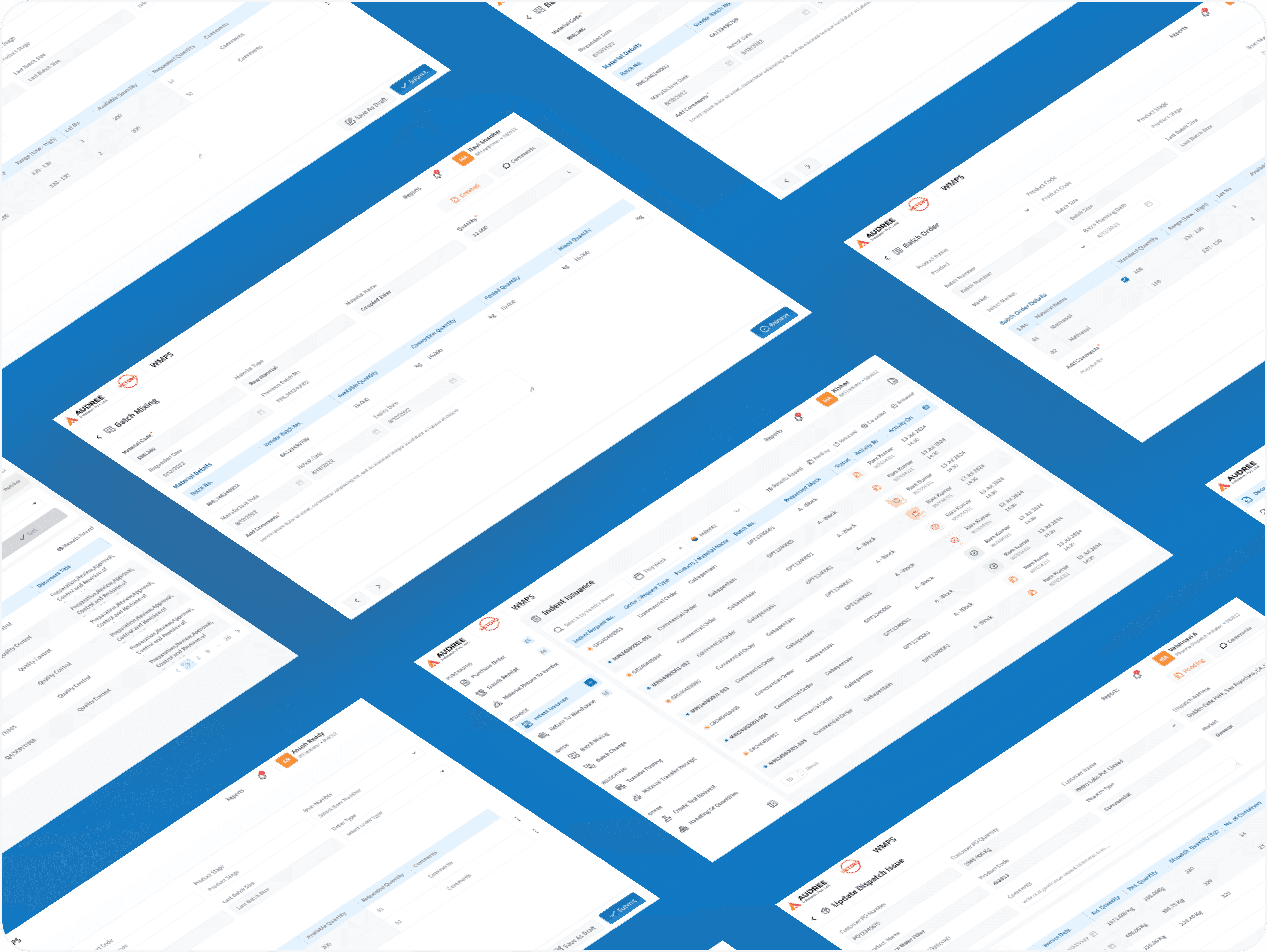

Seamless Material Flow, From Warehouse to Production

Seamless Material Flow, From Warehouse to Production

Seamless Material Flow, From Warehouse to Production

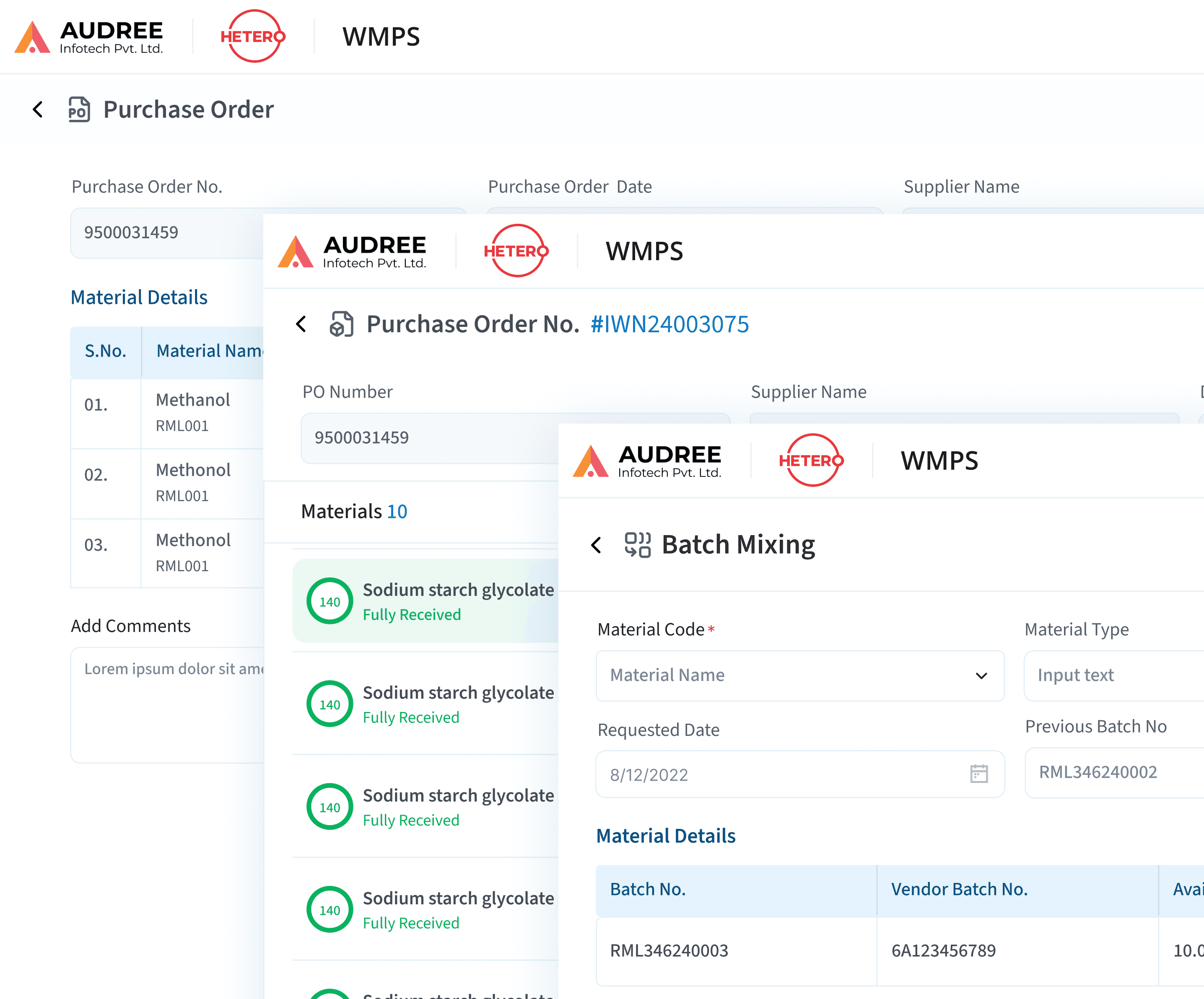

We streamlined the warehouse module to unify every stage from material indent and purchase order to batch mixing and dispatch. Clear hierarchies, status tags, and guided actions now ensure real-time traceability, reduced manual effort, and smoother coordination across teams.

We streamlined the warehouse module to unify every stage from material indent and purchase order to batch mixing and dispatch. Clear hierarchies, status tags, and guided actions now ensure real-time traceability, reduced manual effort, and smoother coordination across teams.

We streamlined the warehouse module to unify every stage from material indent and purchase order to batch mixing and dispatch. Clear hierarchies, status tags, and guided actions now ensure real-time traceability, reduced manual effort, and smoother coordination across teams.

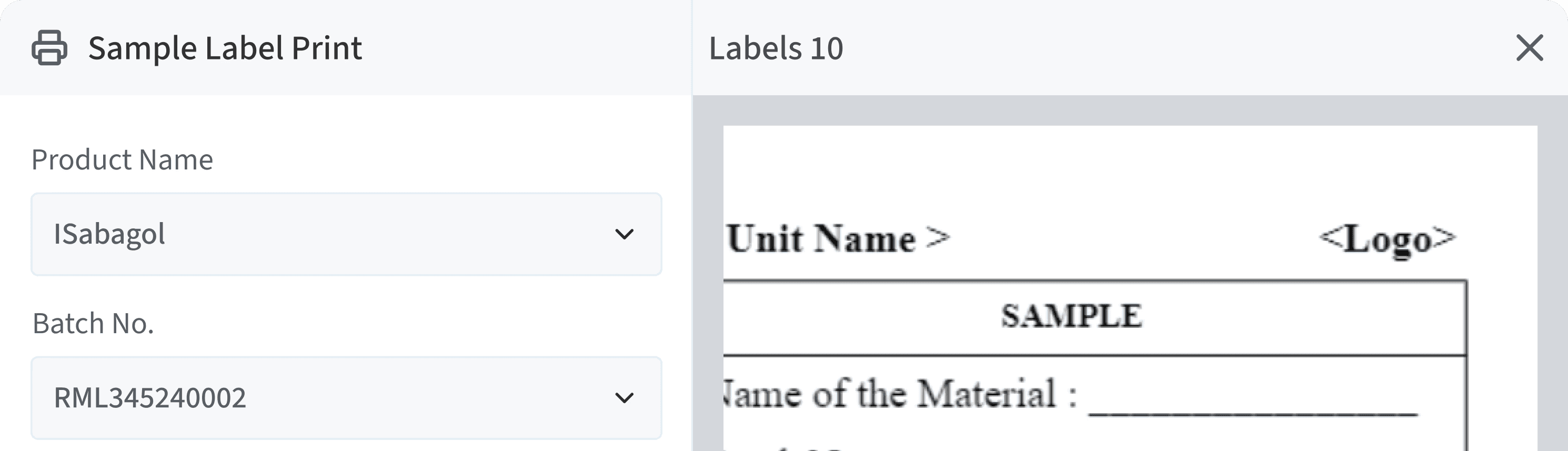

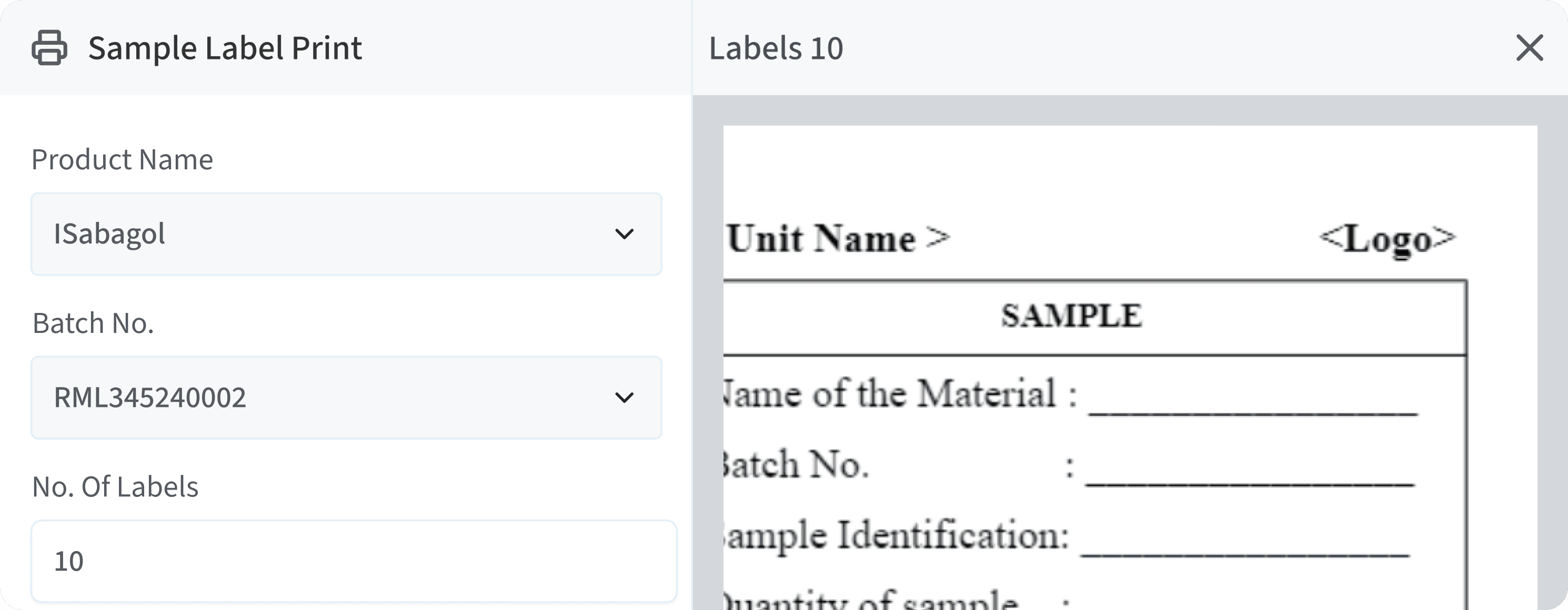

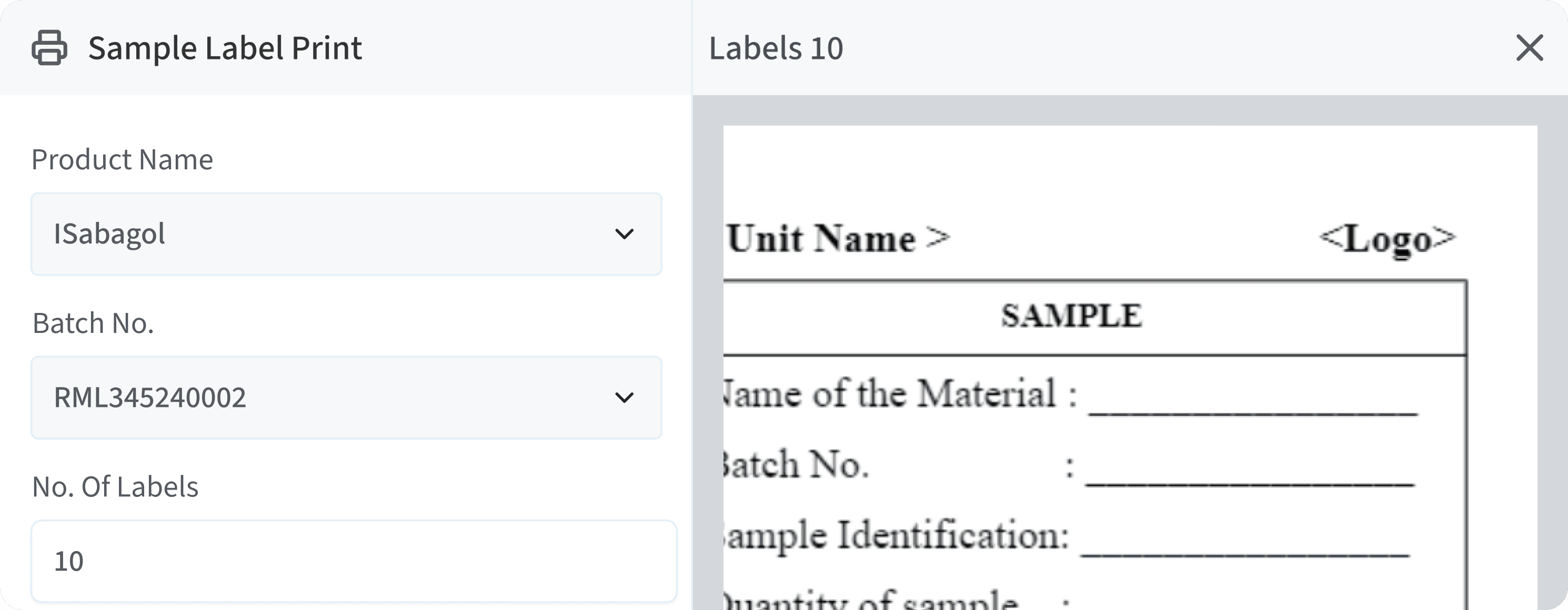

Making Dispatch Simple and Traceable

Making Dispatch Simple and Traceable

Making Dispatch Simple and Traceable

We simplified the dispatch process by enabling clear traceability from packing to delivery. Label printing and verification steps were unified into one flow helping teams manage dispatches faster, reduce manual checks, and ensure every batch leaves the warehouse accurately.

We simplified the dispatch process by enabling clear traceability from packing to delivery. Label printing and verification steps were unified into one flow helping teams manage dispatches faster, reduce manual checks, and ensure every batch leaves the warehouse accurately.

We simplified the dispatch process by enabling clear traceability from packing to delivery. Label printing and verification steps were unified into one flow helping teams manage dispatches faster, reduce manual checks, and ensure every batch leaves the warehouse accurately.

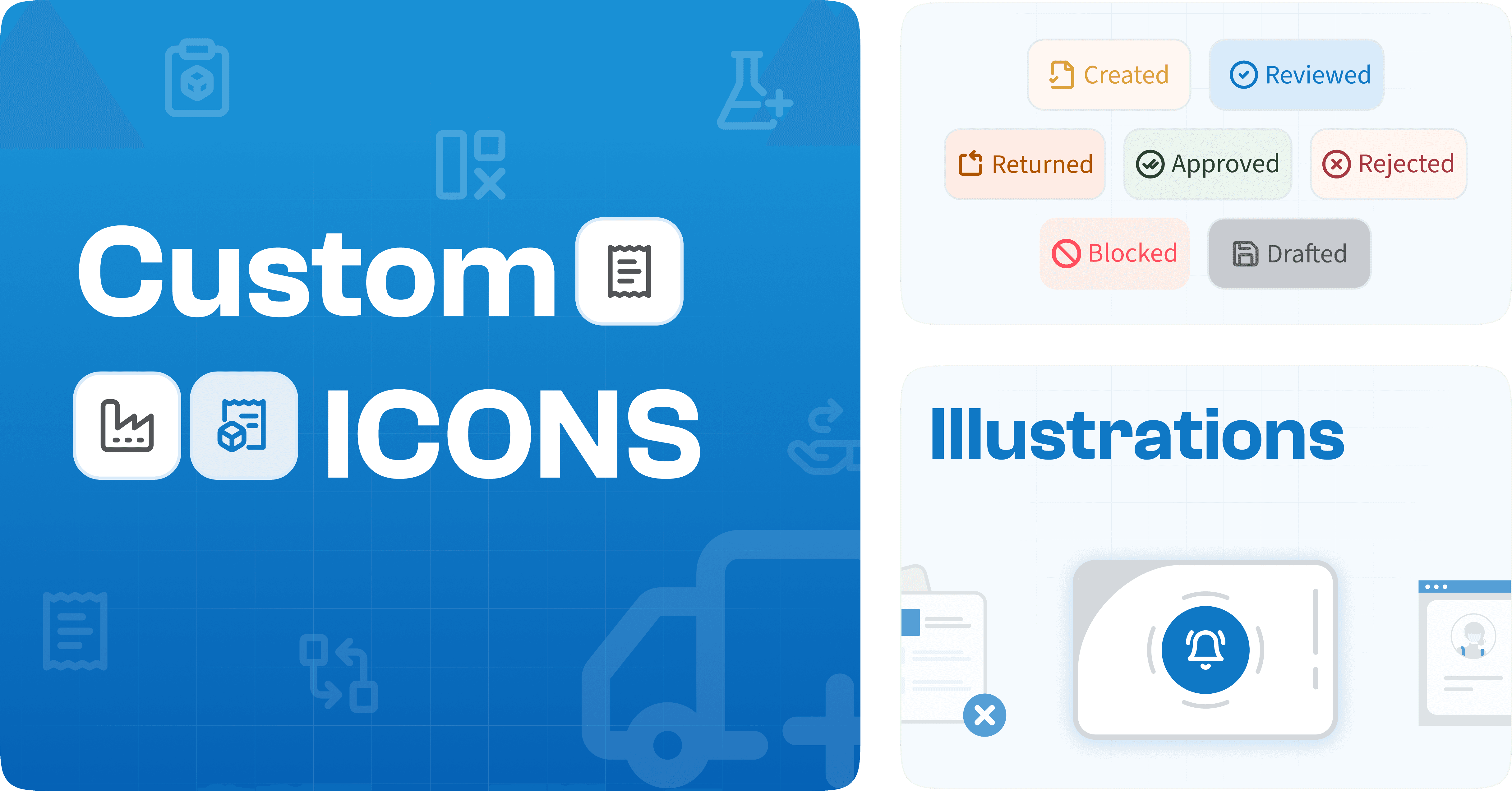

Consistent Visual Language for Clarity

Consistent Visual Language for Clarity

Consistent Visual Language for Clarity

We created custom icons and illustrations tailored for pharma workflows making every status, action, and alert instantly recognizable. This consistency across the suite enhances usability

We created custom icons and illustrations tailored for pharma workflows making every status, action, and alert instantly recognizable. This consistency across the suite enhances usability

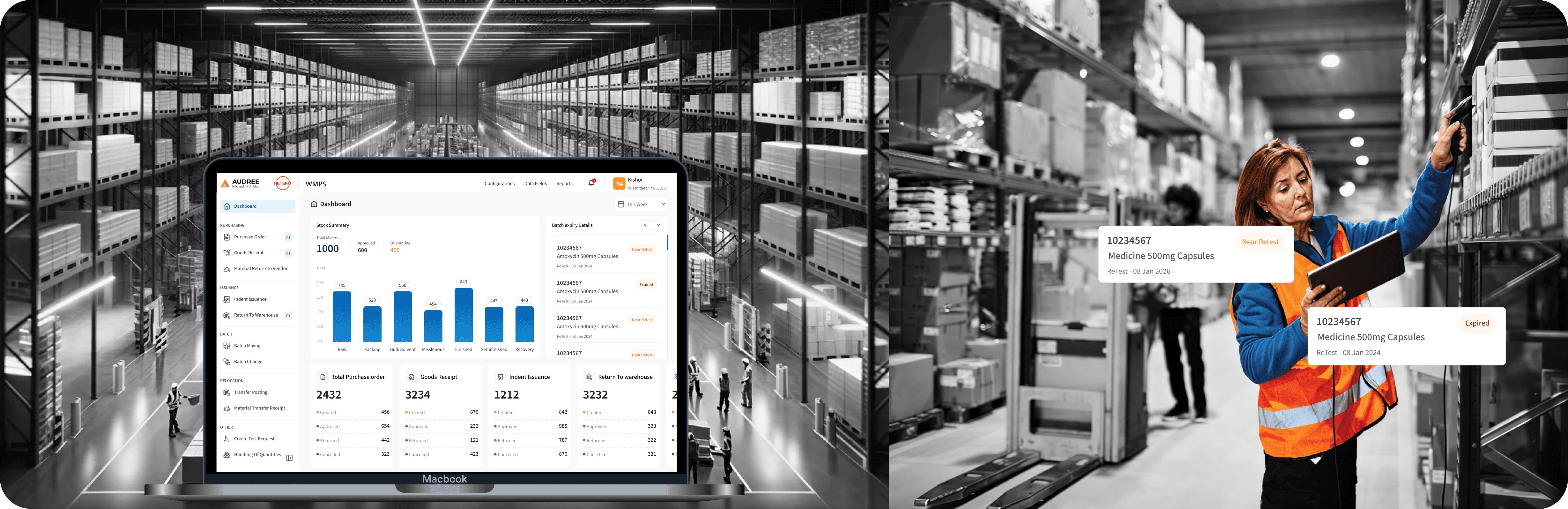

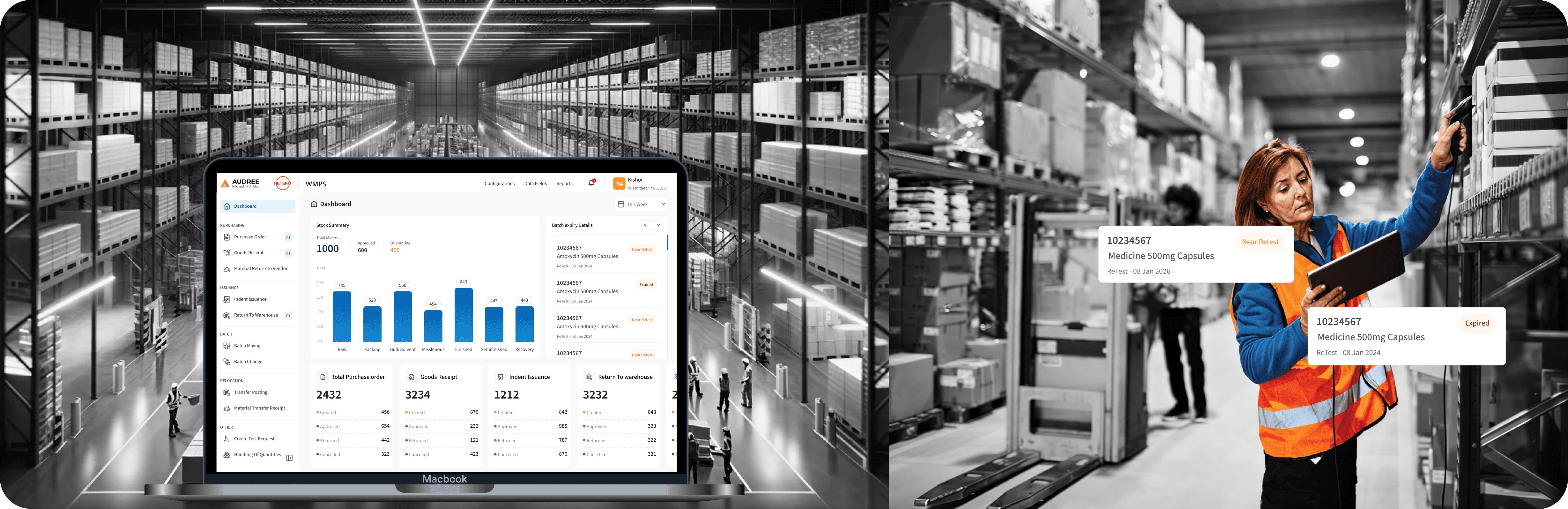

A Faster, Clearer, and More Reliable WMPS

A Faster, Clearer, and More Reliable WMPS

A Faster, Clearer, and More Reliable WMPS

The redesigned WMPS offers a seamless warehouse experience with clearer data, effortless navigation, and precise workflows helping teams work faster, reduce errors, and maintain control.

The redesigned WMPS offers a seamless warehouse experience with clearer data, effortless navigation, and precise workflows helping teams work faster, reduce errors, and maintain control.

Result That Transformed WMPS

Result That Transformed WMPS

Result That Transformed WMPS

Streamlined material flows, real-time visibility, and a fully digital warehouse process improved accuracy, speed, and traceability across pharma operations.

Streamlined material flows, real-time visibility, and a fully digital warehouse process improved accuracy, speed, and traceability across pharma operations.

Stronger Compliance & Traceability

Stronger Compliance & Traceability

Stronger Compliance & Traceability

Structured workflows, clear status indicators, and system-driven validations reduced manual errors and strengthened audit readiness.

Structured workflows, clear status indicators, and system-driven validations reduced manual errors and strengthened audit readiness.

Structured workflows, clear status indicators, and system-driven validations reduced manual errors and strengthened audit readiness.

Faster API Batch Execution

Simplified dispatch and movement workflows replaced offline coordination, enabling quicker and more predictable warehouse operations.

Reduced Follow-ups & Support Dependency

Clear workflows, better status visibility, and guided actions reduced user confusion and day-to-day support dependency.

Faster API Batch Execution

Faster API Batch Execution

Simplified dispatch and movement workflows replaced offline coordination, enabling quicker and more predictable warehouse operations.

Simplified dispatch and movement workflows replaced offline coordination, enabling quicker and more predictable warehouse operations.

Reduced Follow-ups & Support Dependency

Reduce Follow-ups & Support Dependency

Clear workflows, better status visibility, and guided actions reduced user confusion and day-to-day support dependency.

Clear workflows, better status visibility, and guided actions reduced user confusion and day-to-day support dependency.

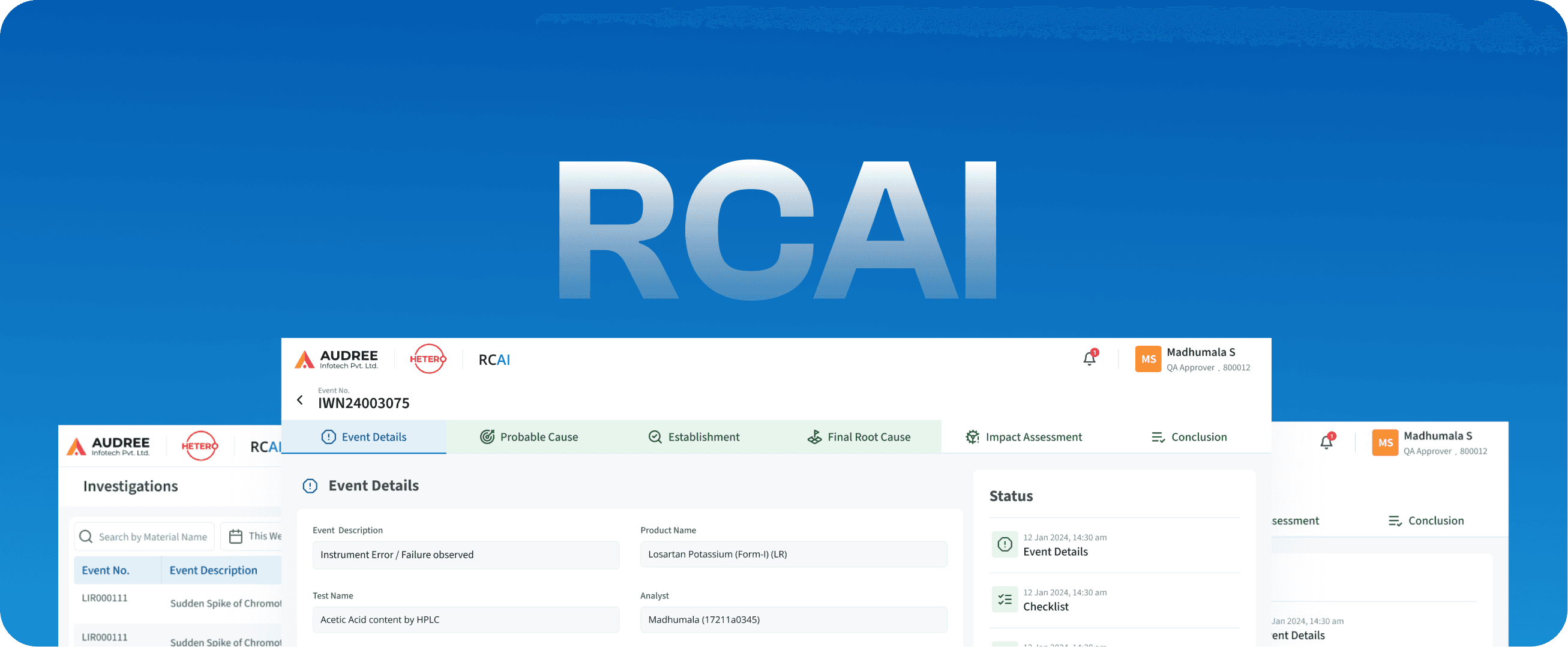

Deep-Dive Into More System

Deep-Dive Into More System

Deep-Dive Into More System

Browse every optimised Software and explore how legacy systems became intuitive.

Browse every optimised Software and explore how legacy systems became intuitive.

Browse every optimised Software and explore how legacy systems became intuitive.

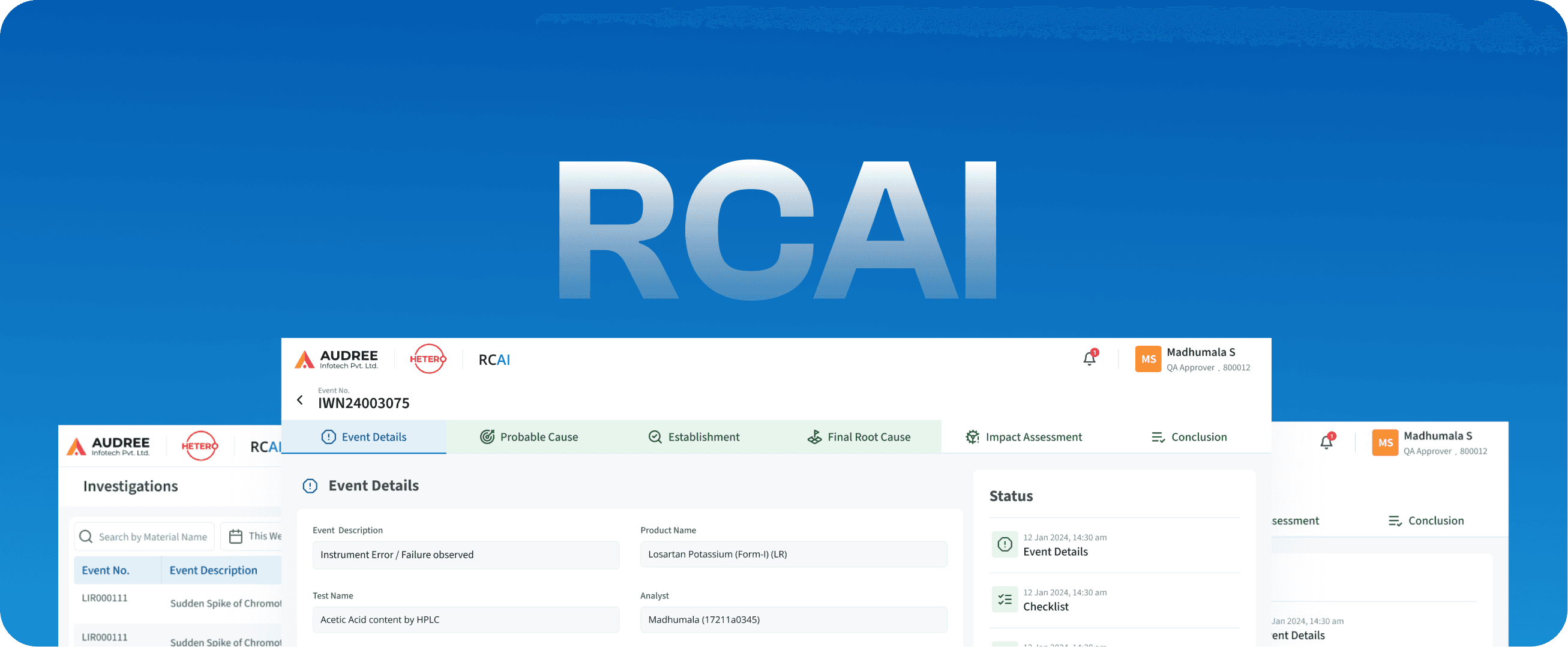

RCAI

Root Cause Analysis with Intelligence

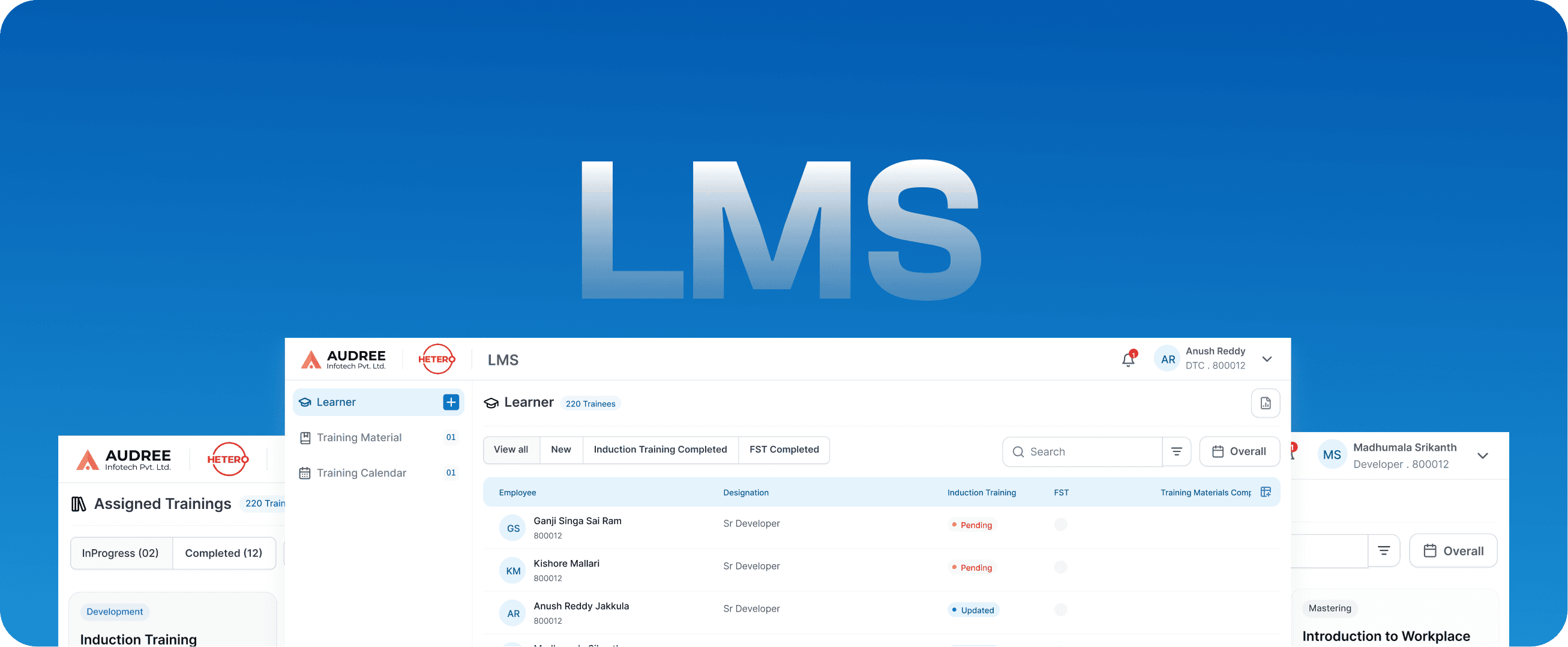

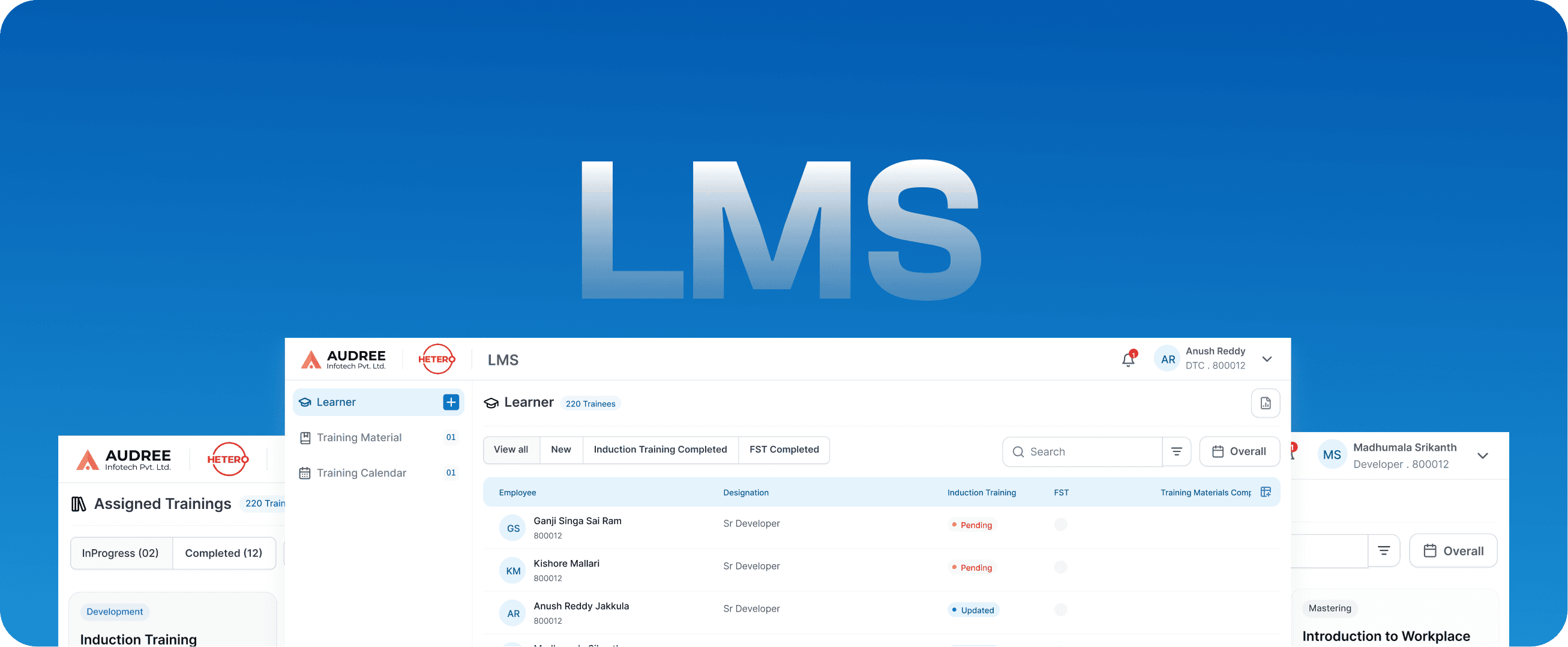

LMS

Learning Management System

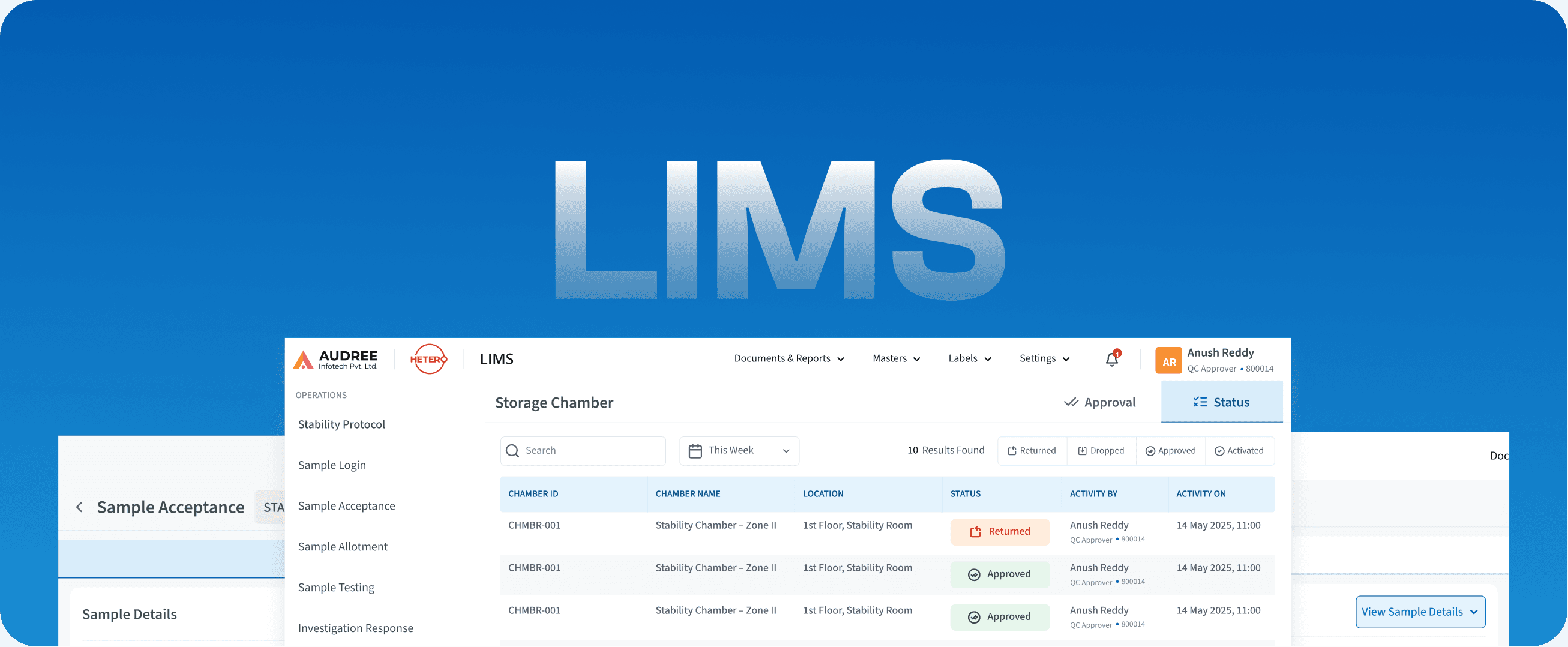

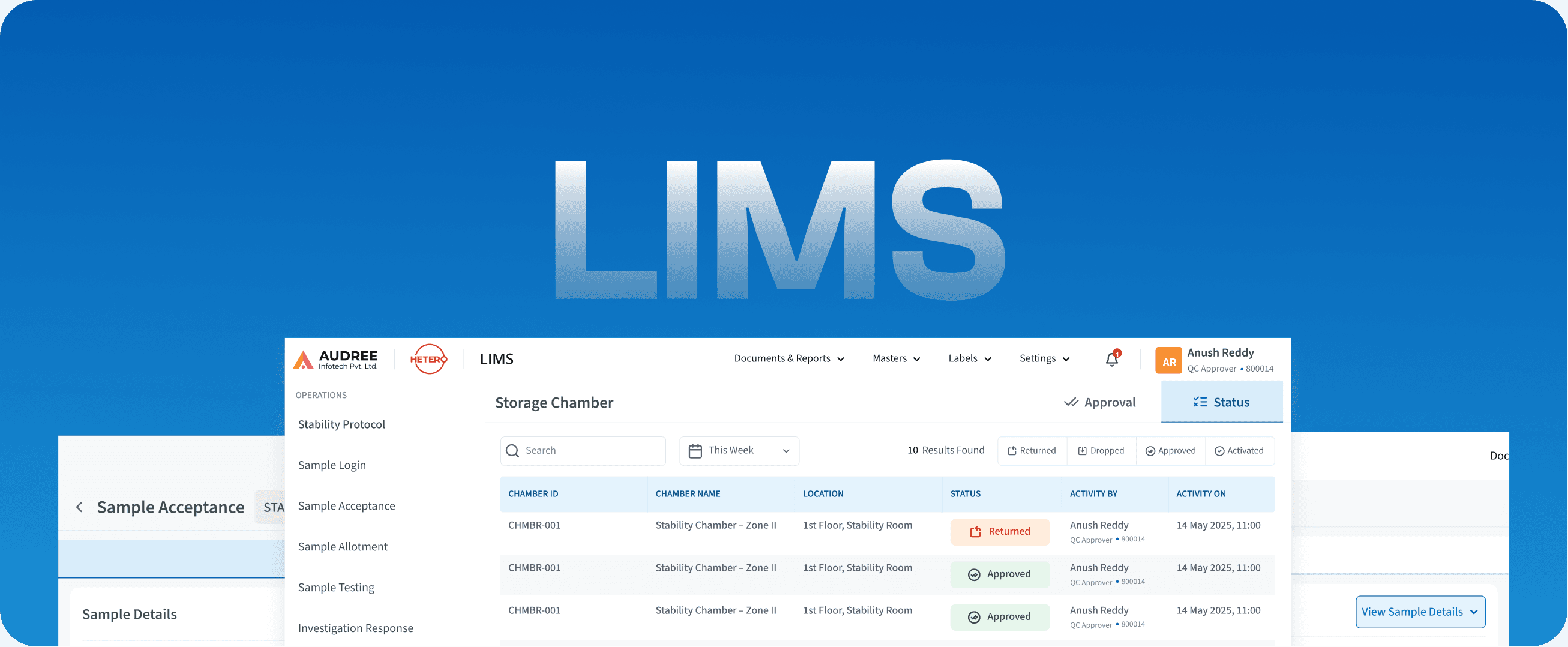

LIMS

Laboratory Information Management System

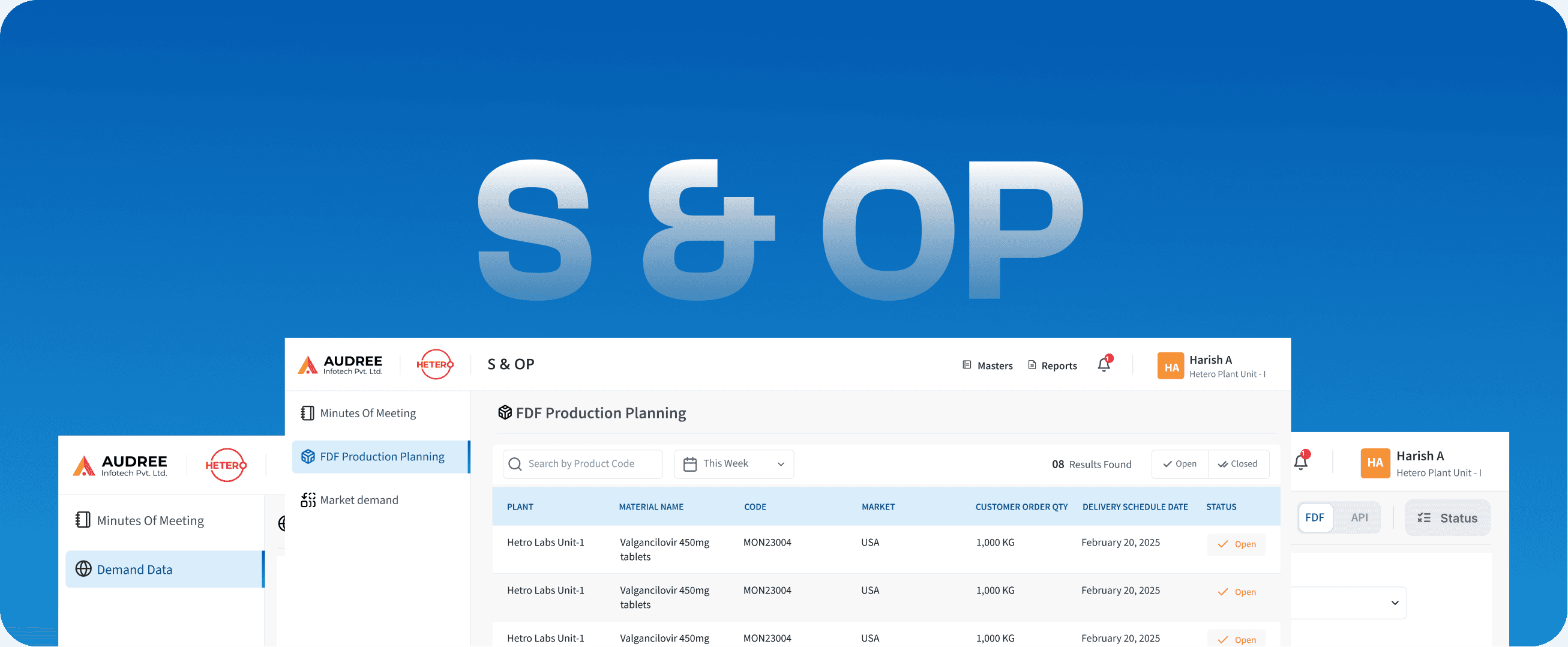

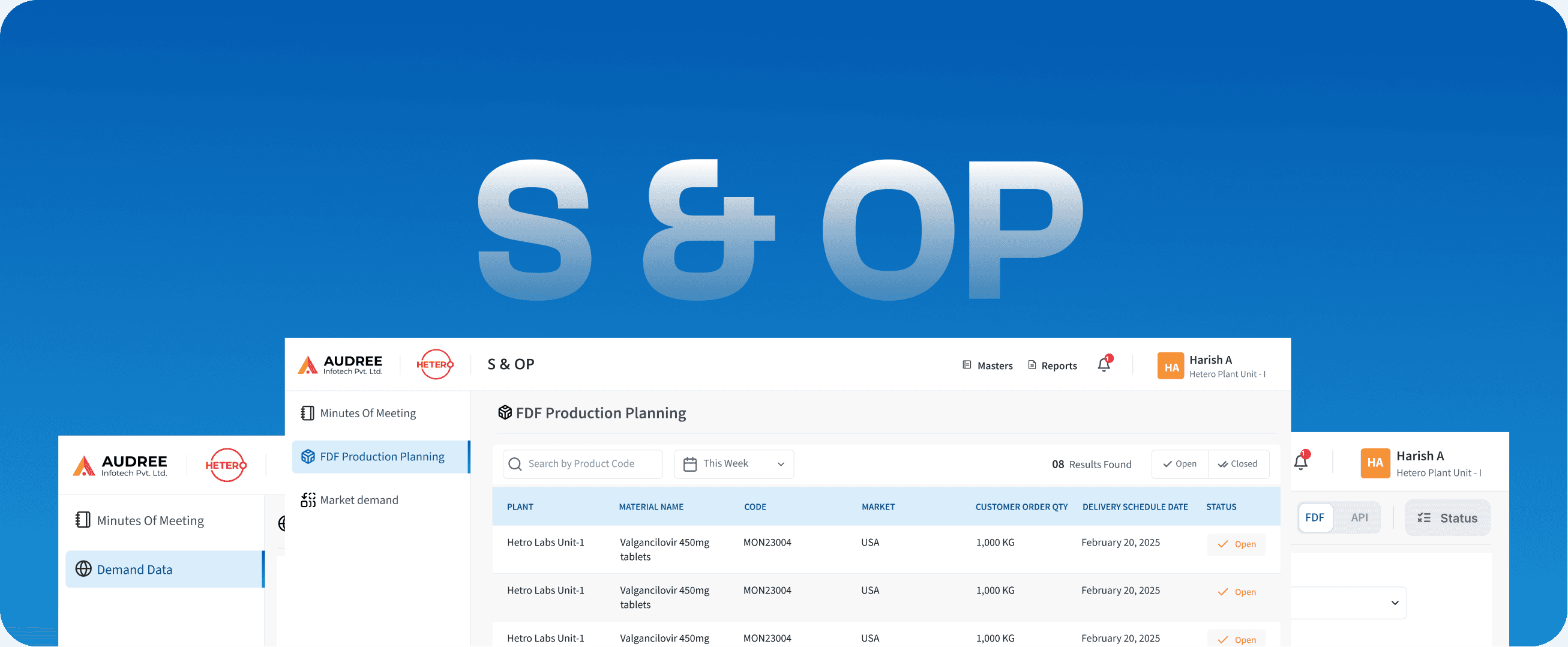

S & OP

Sales & Operations Planning

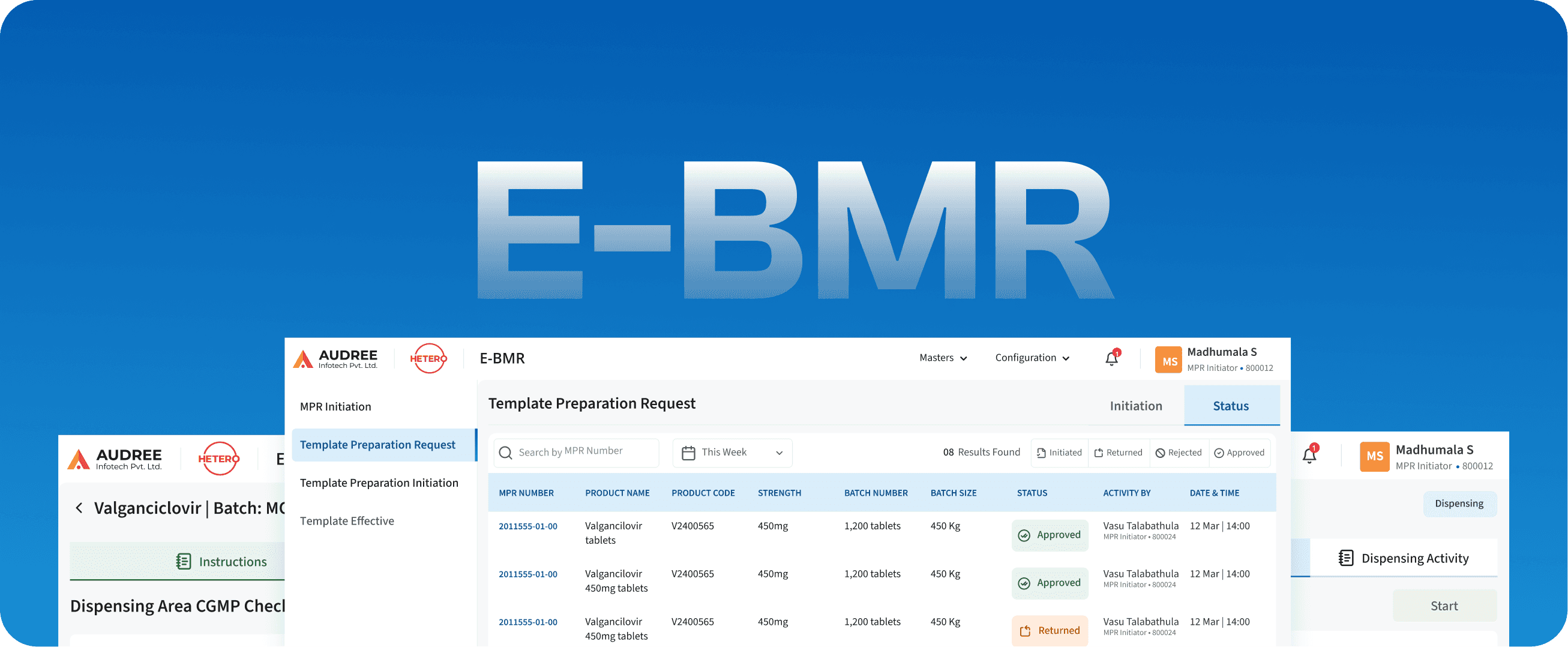

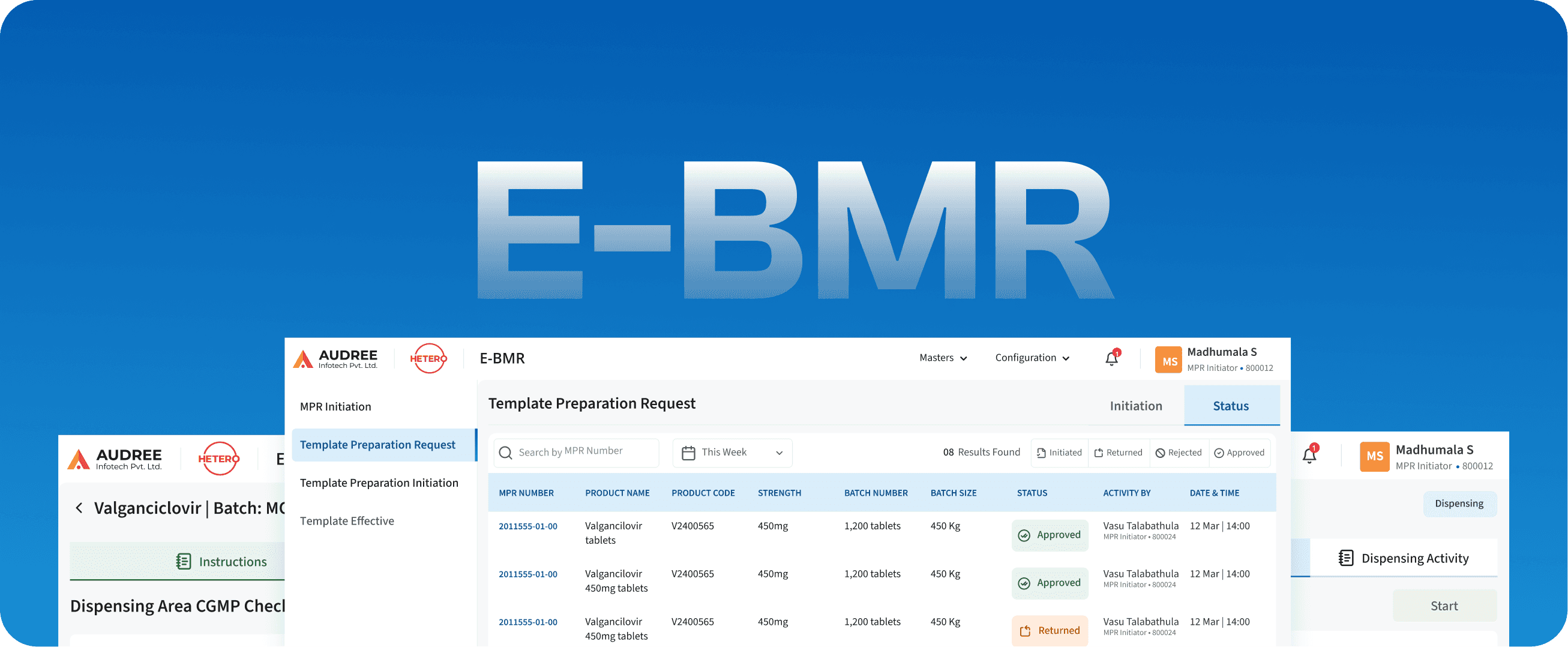

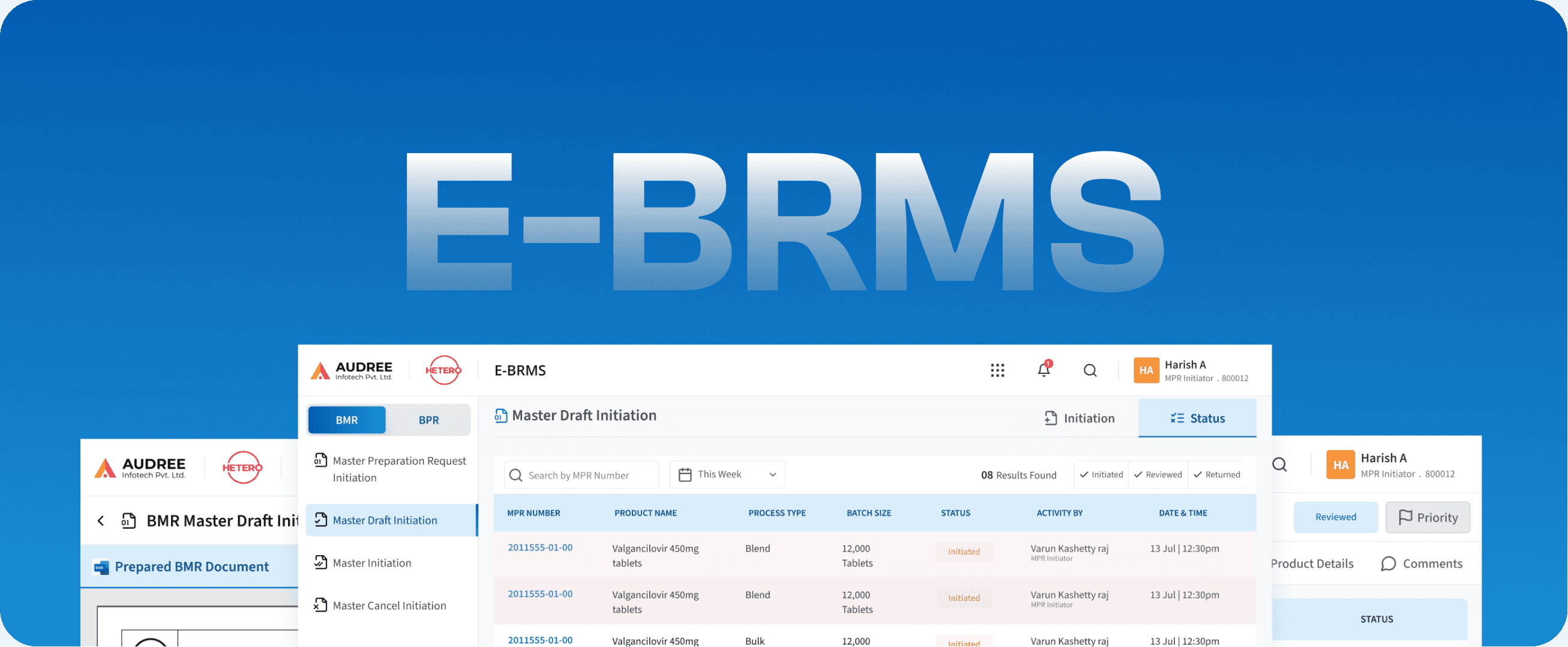

E-BMR

Batch Manufacturing Recall

WMPS

Warehouse Management System

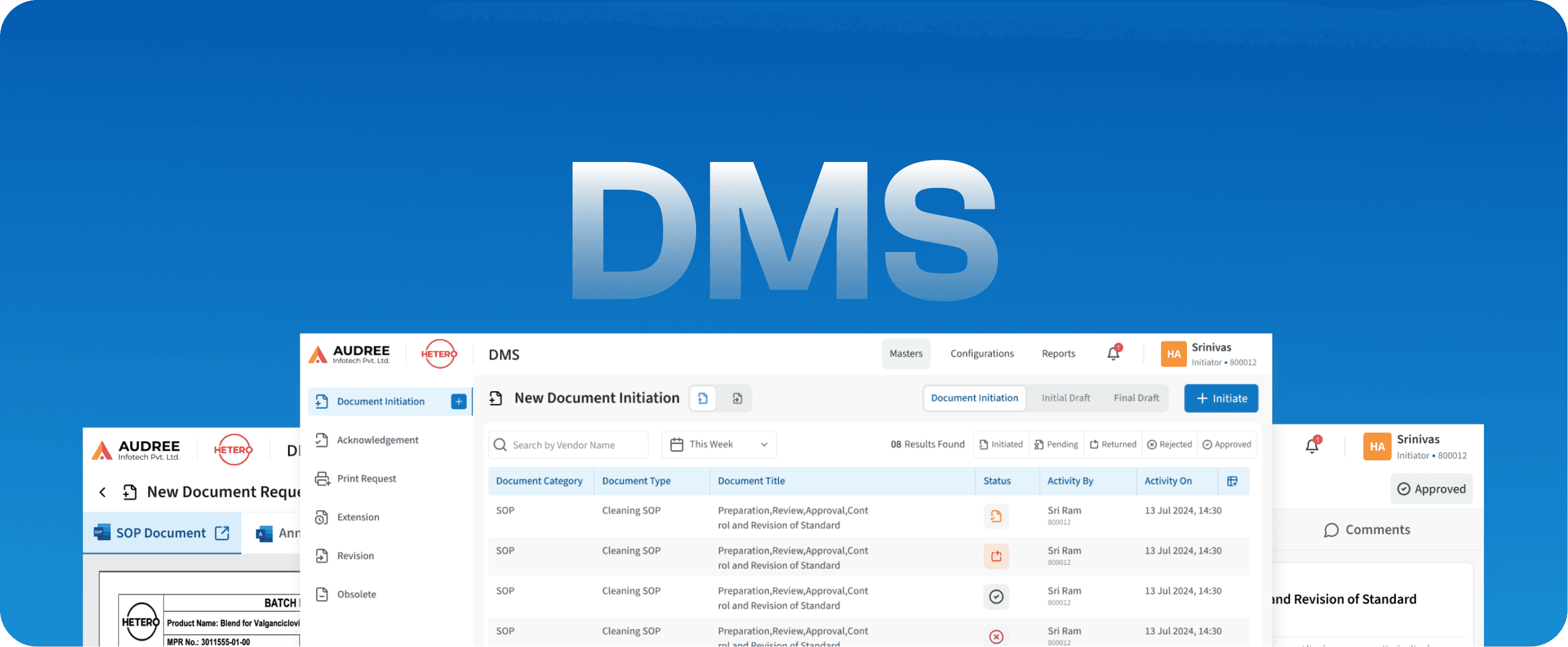

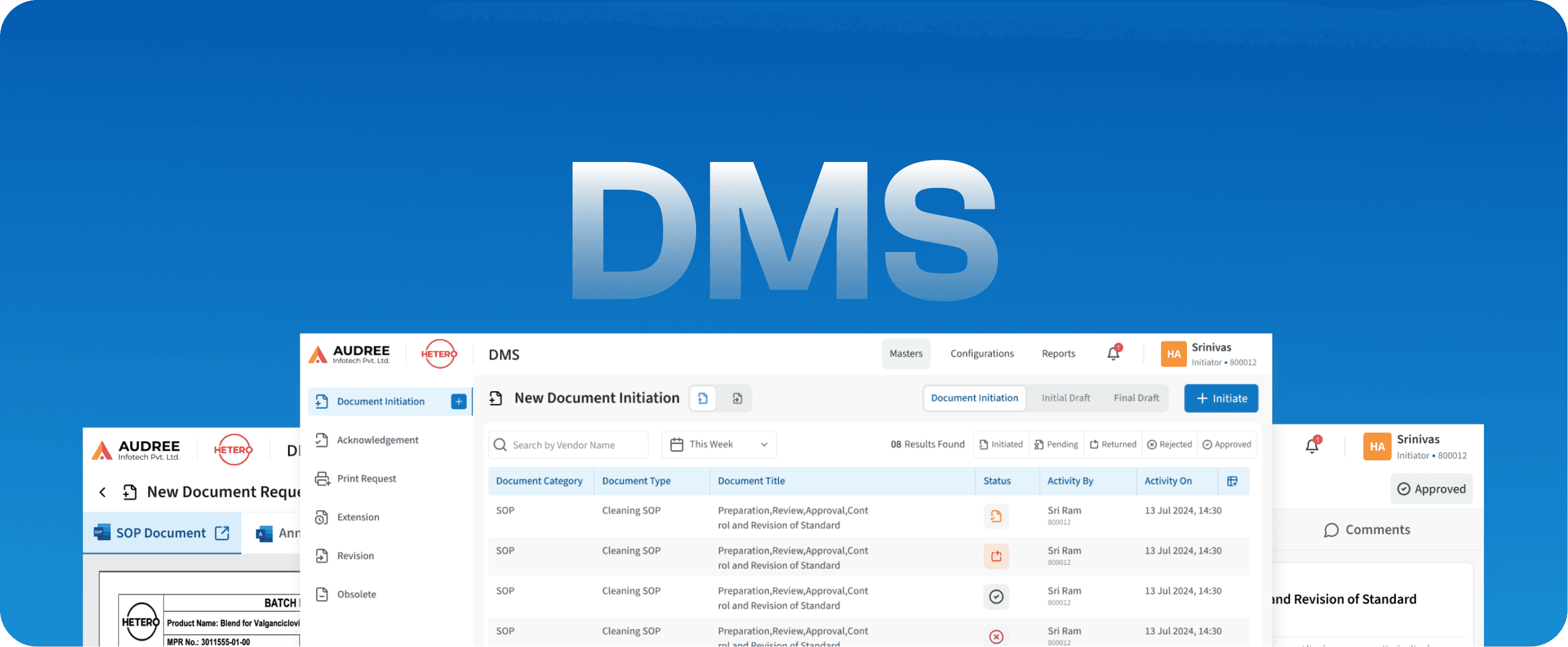

DMS

Document Management System

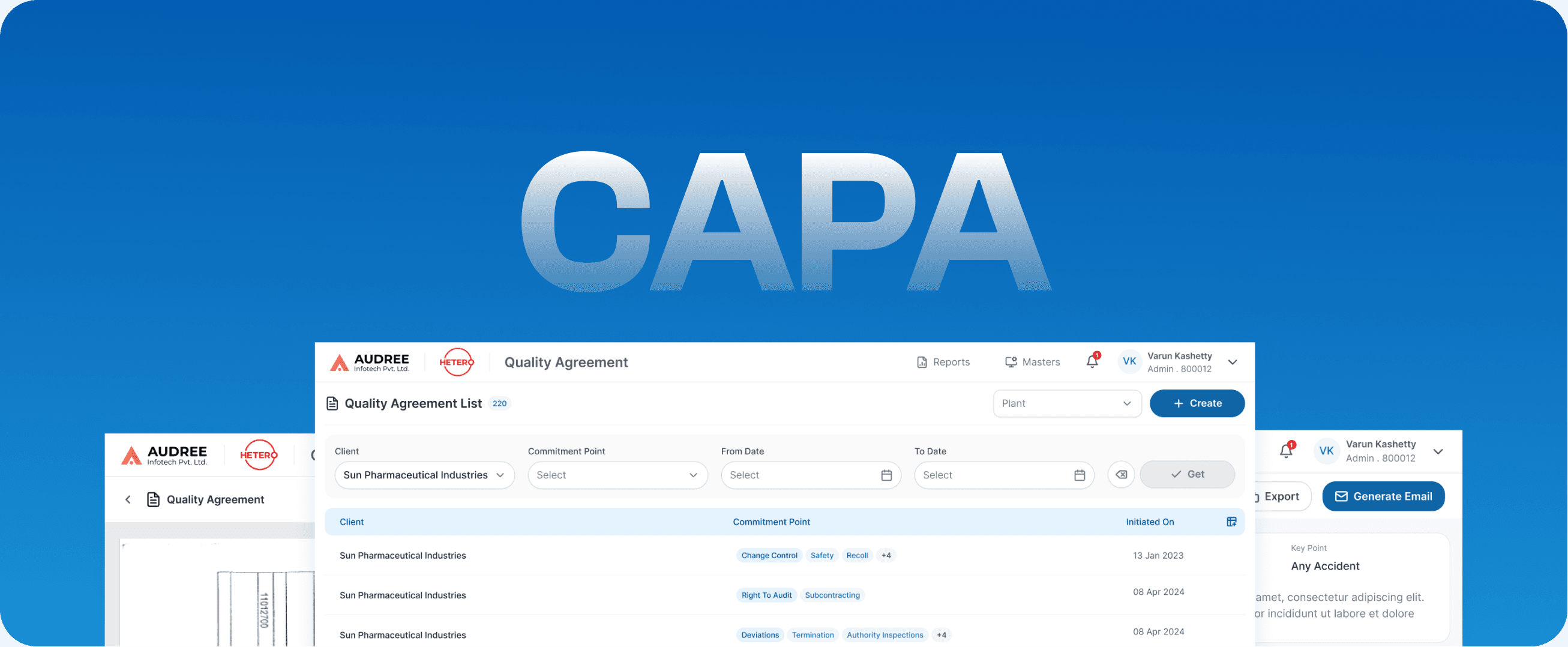

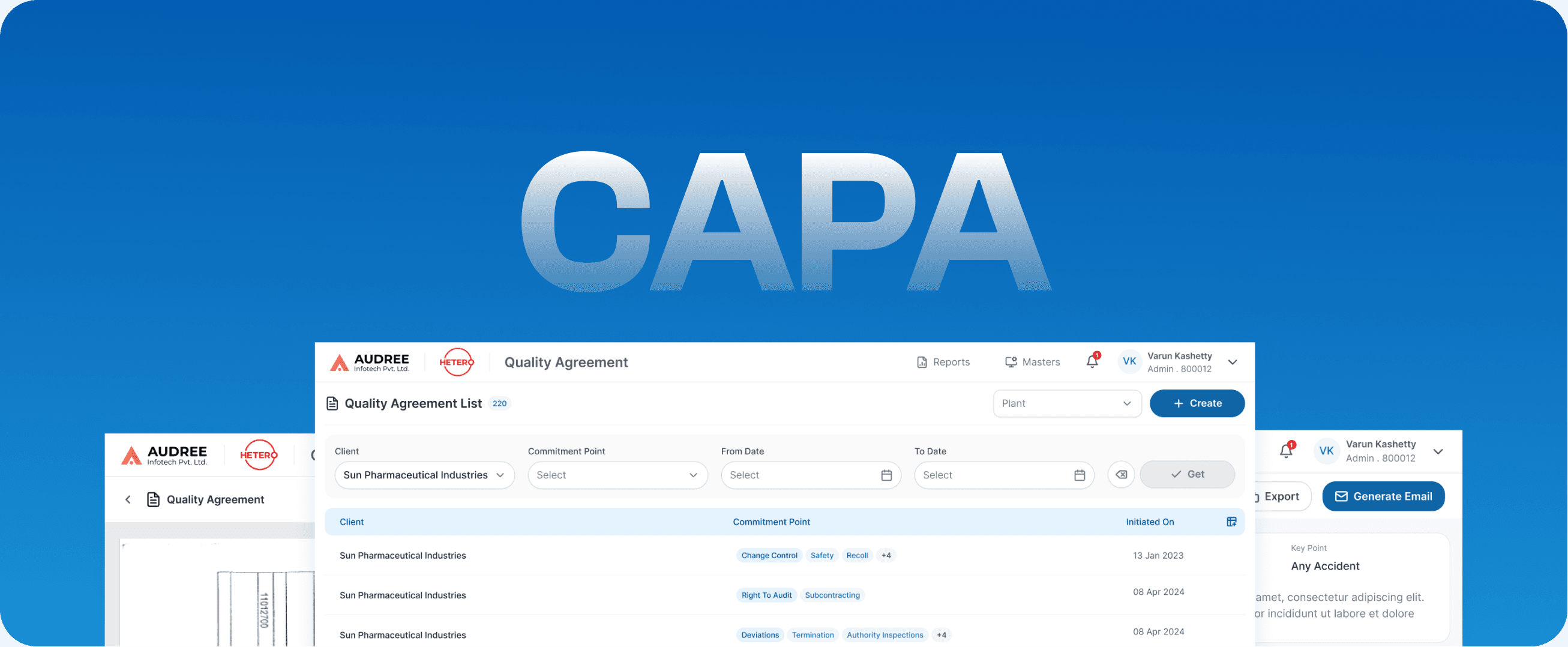

CAPA

Corrective And Preventive Actions

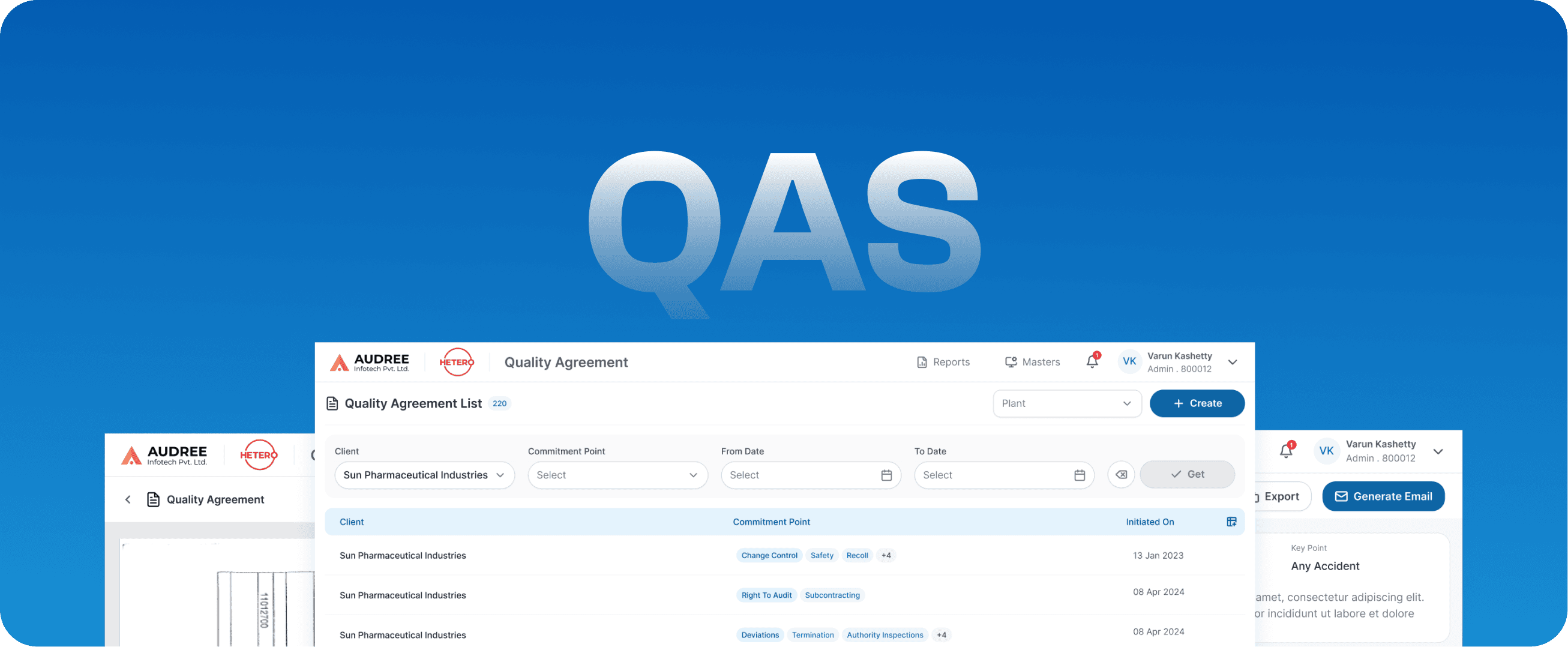

QAS

Quality Agreement System

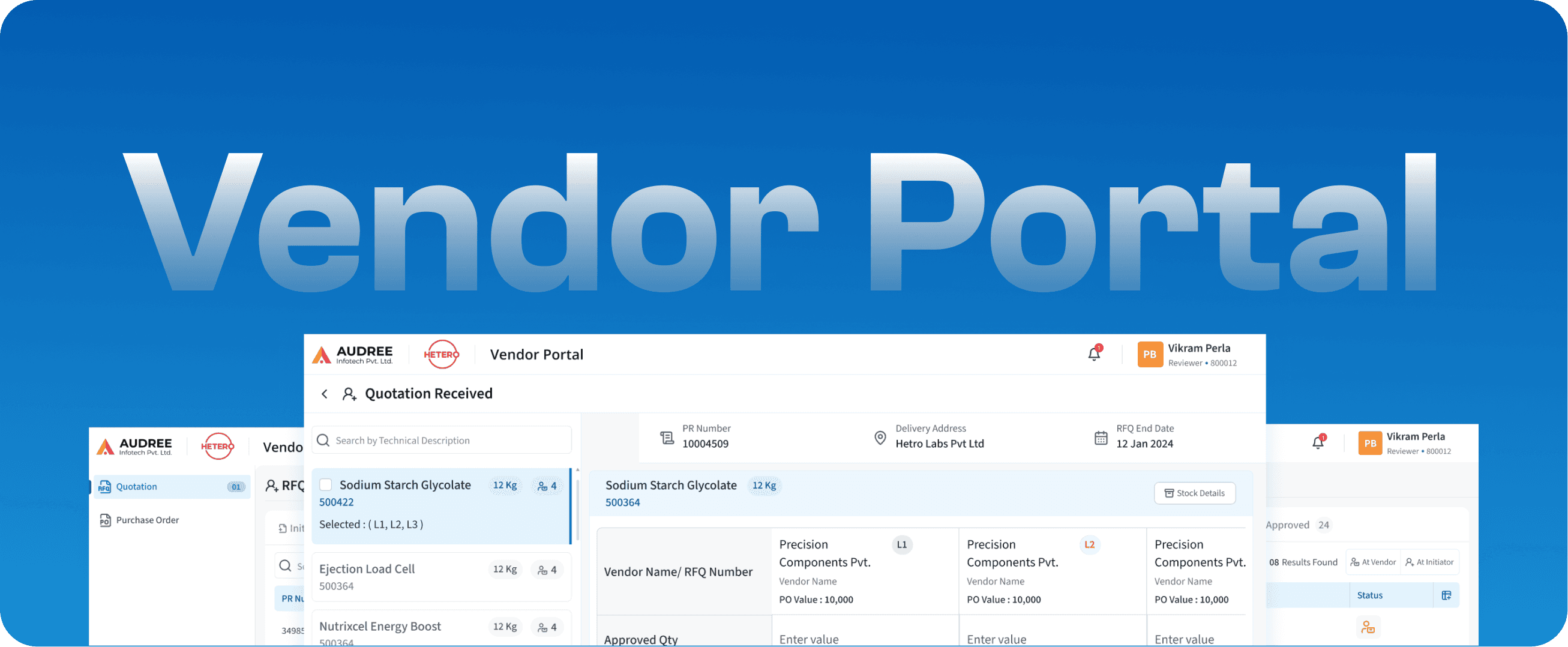

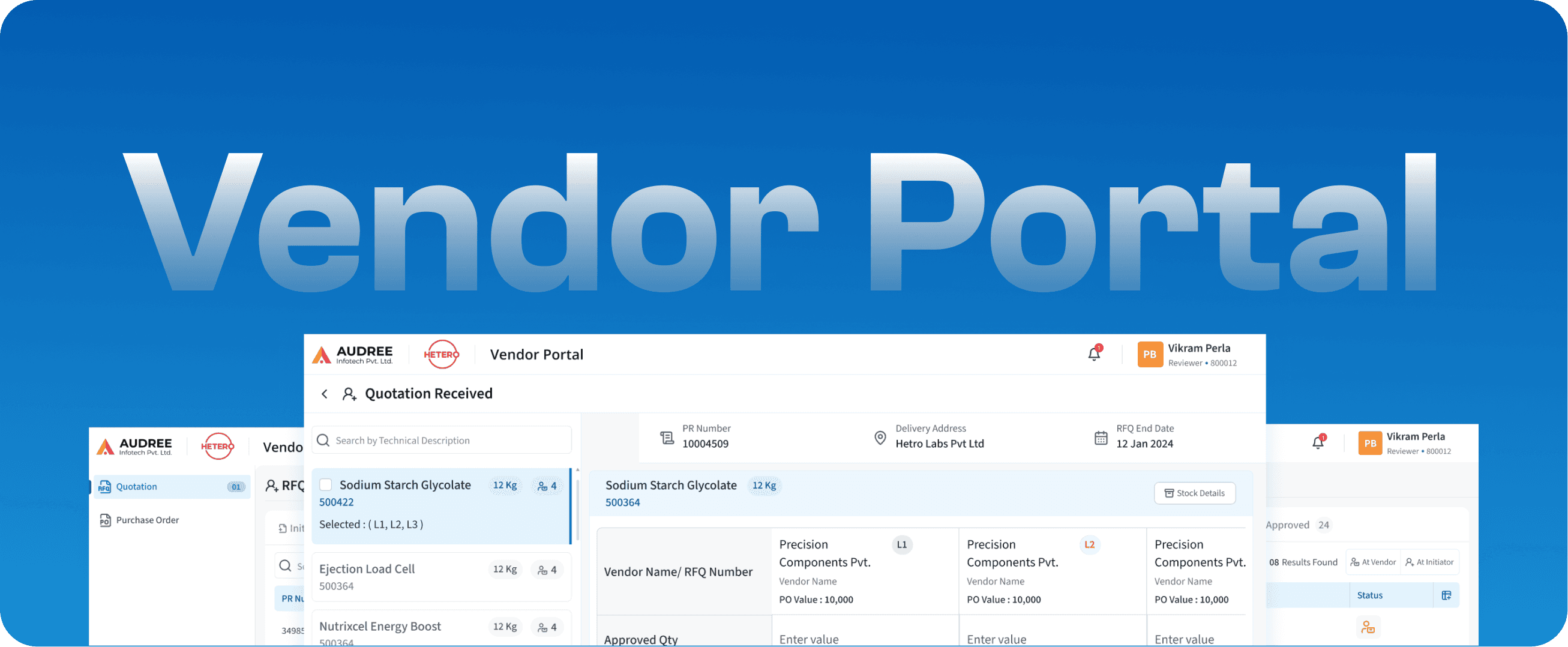

Vendor Portal

Vendor Management System

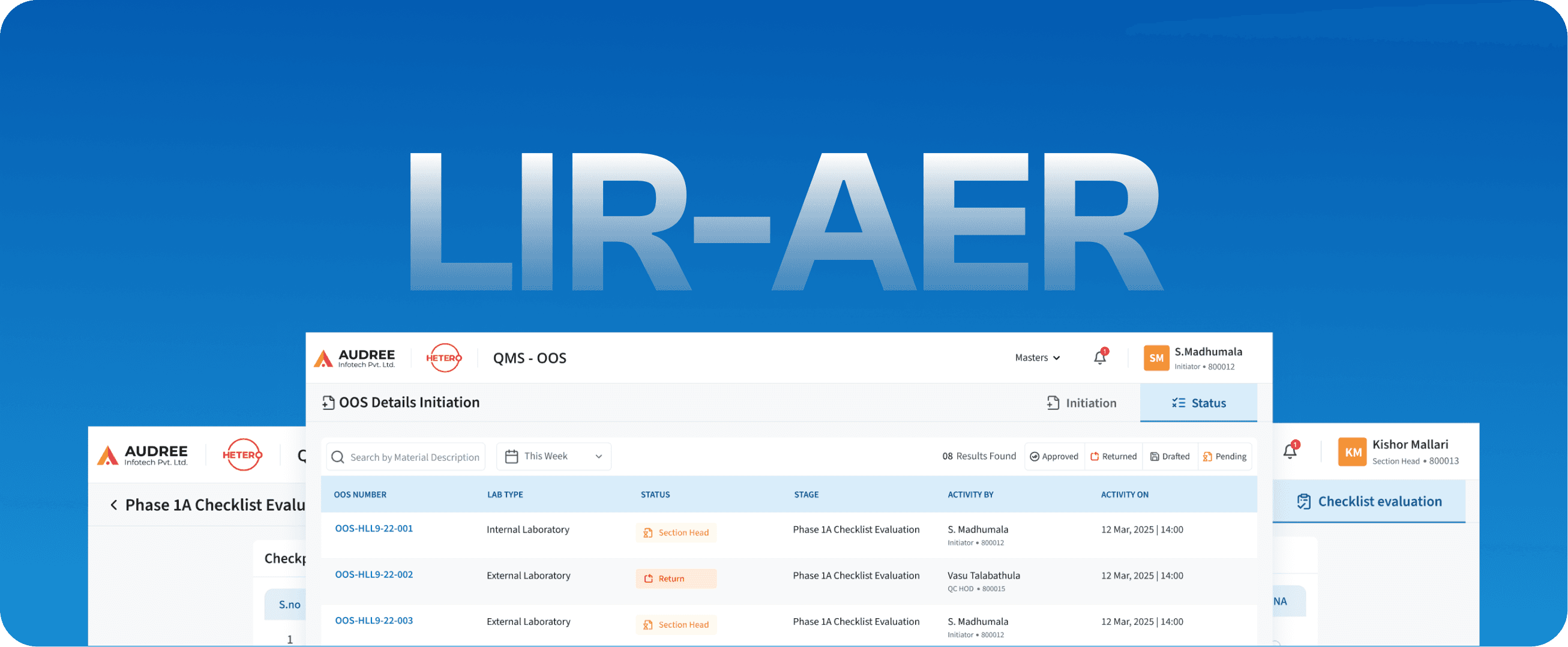

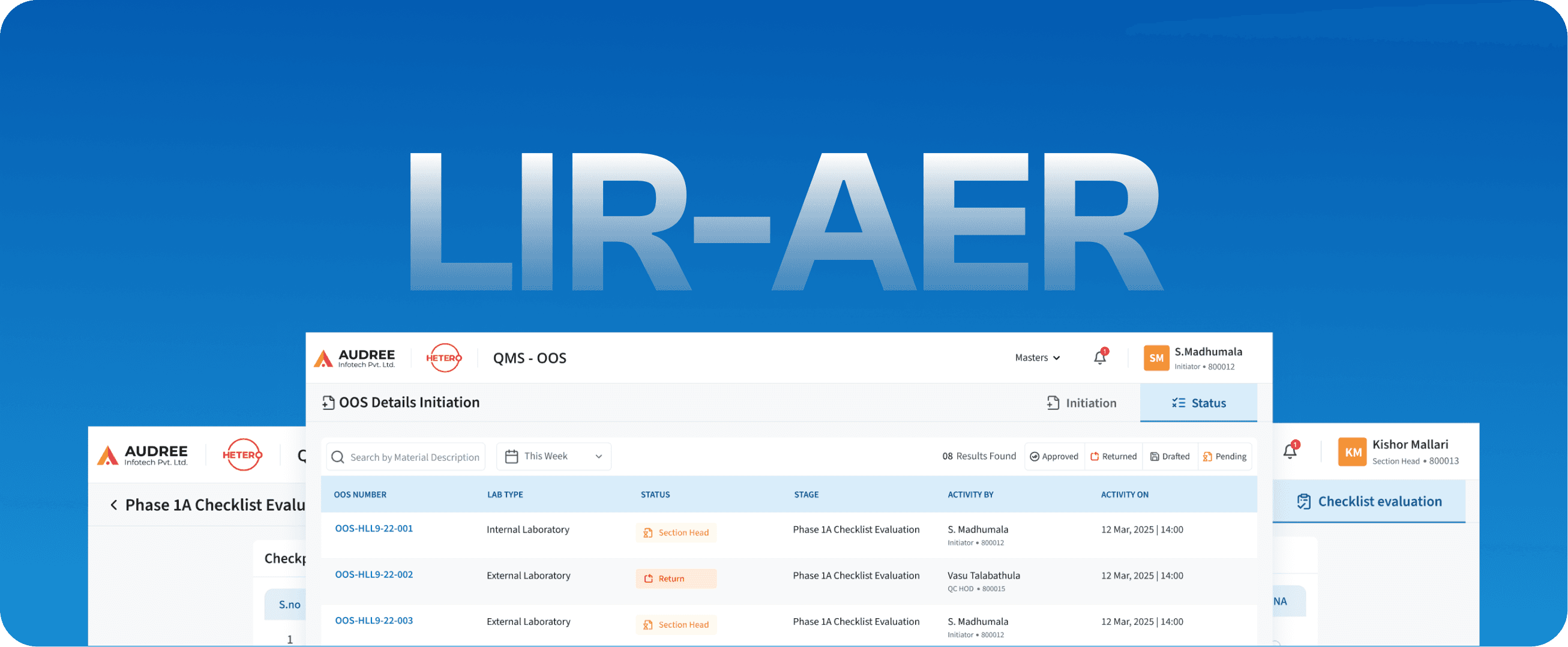

LIR-AER

Laboratory Information Record

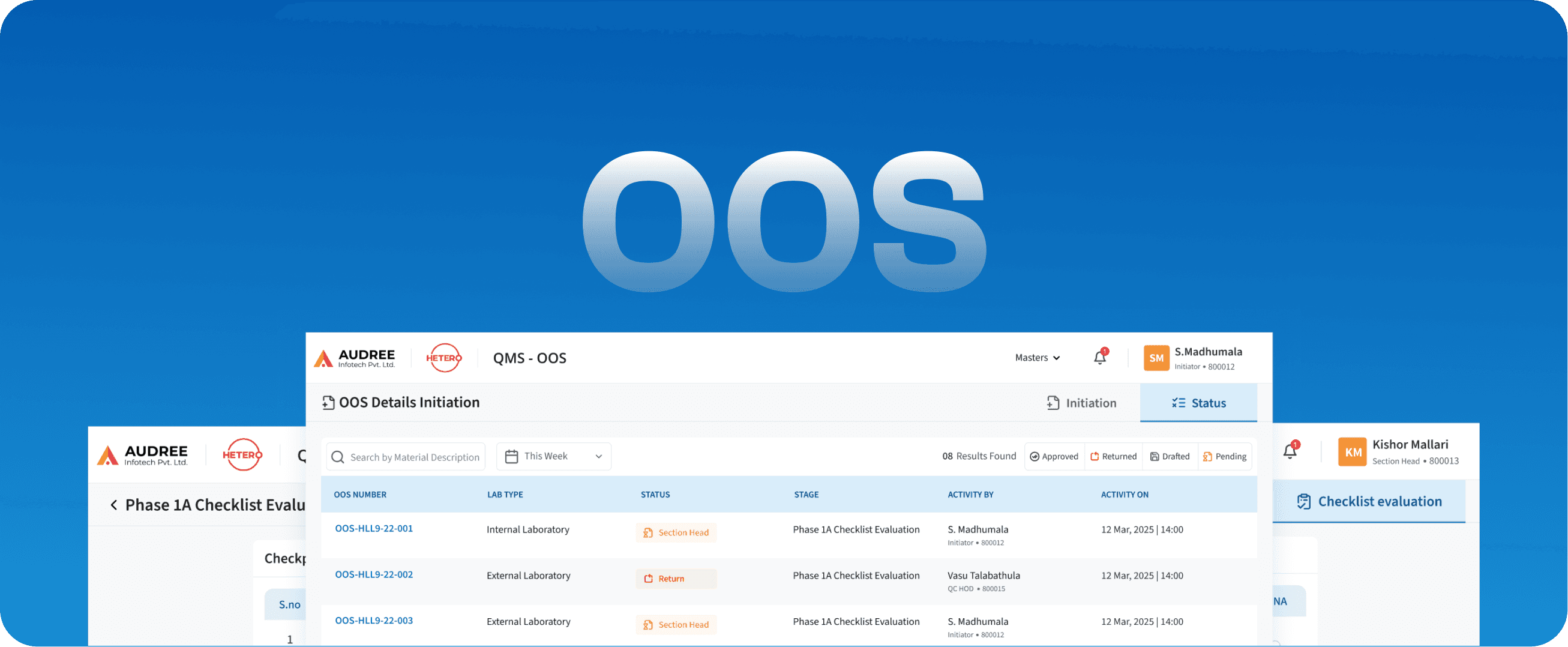

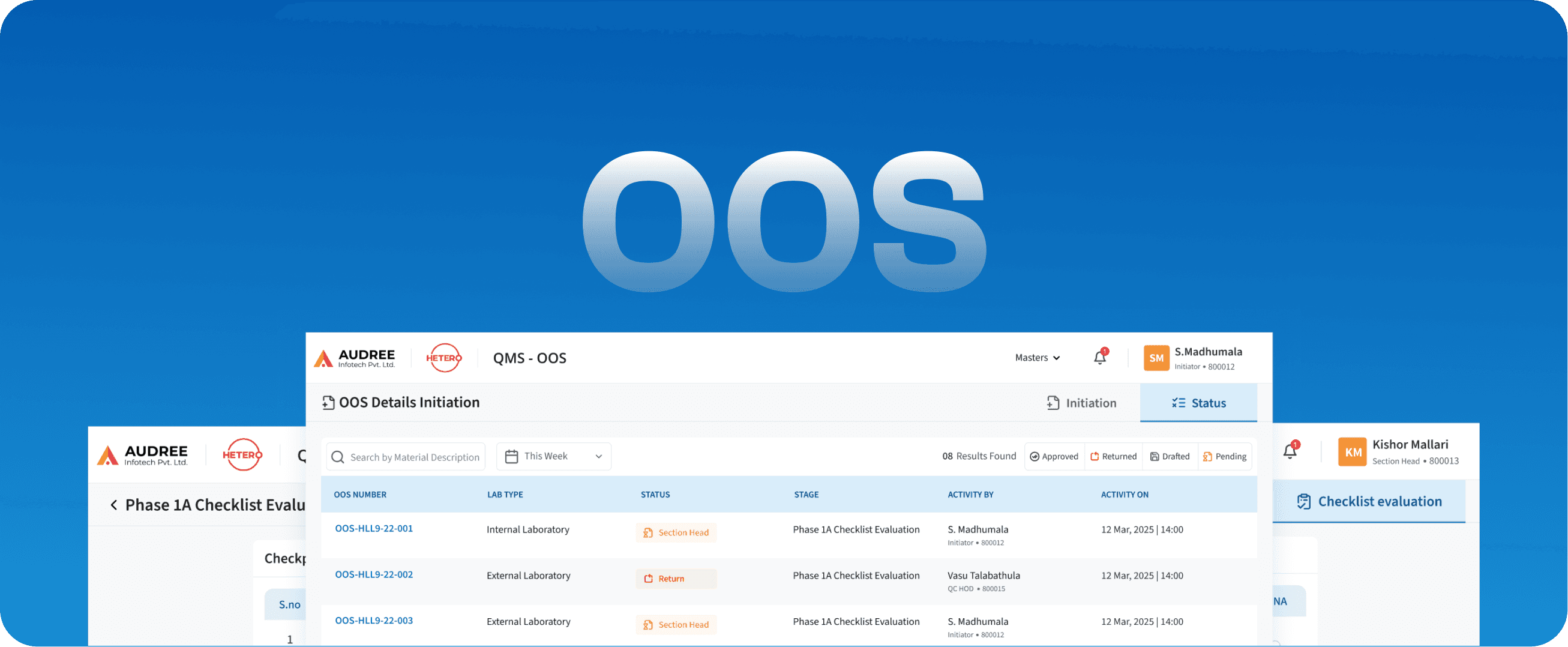

OOS

Out Of Specification

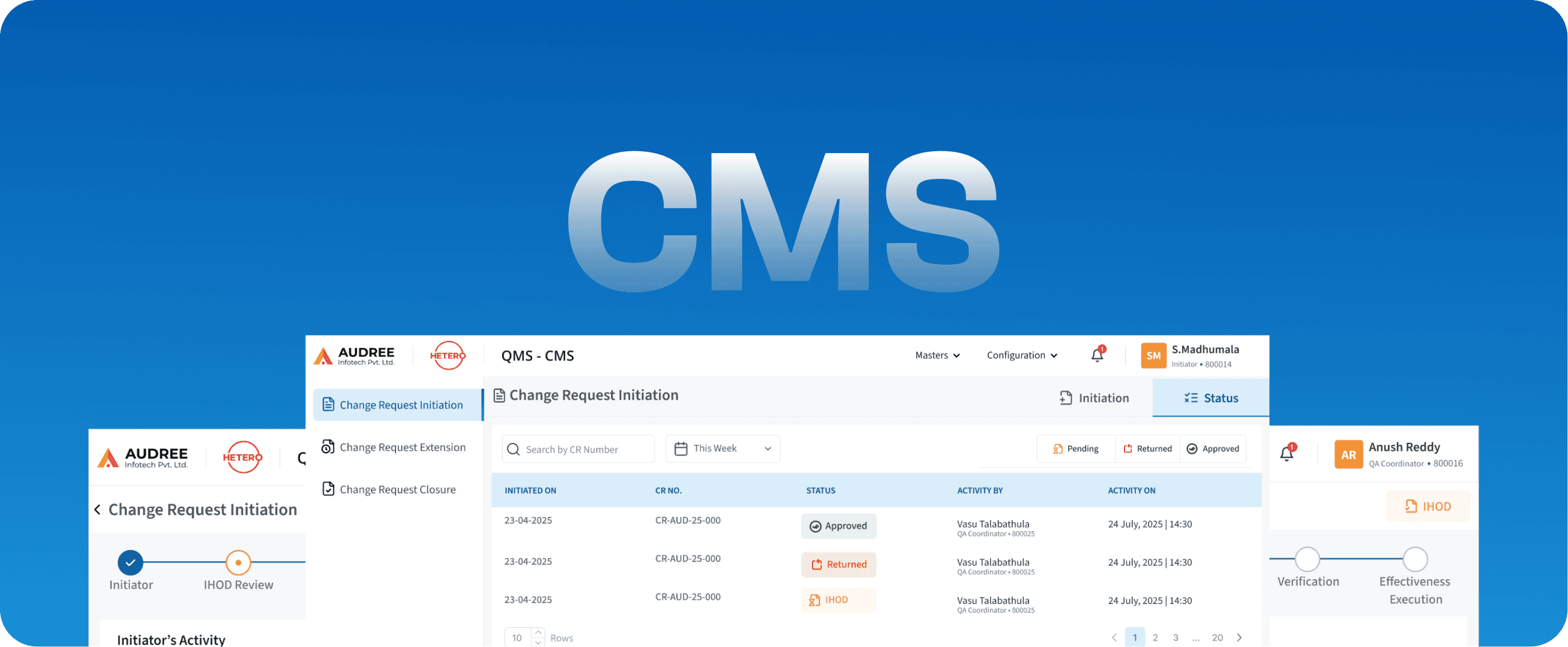

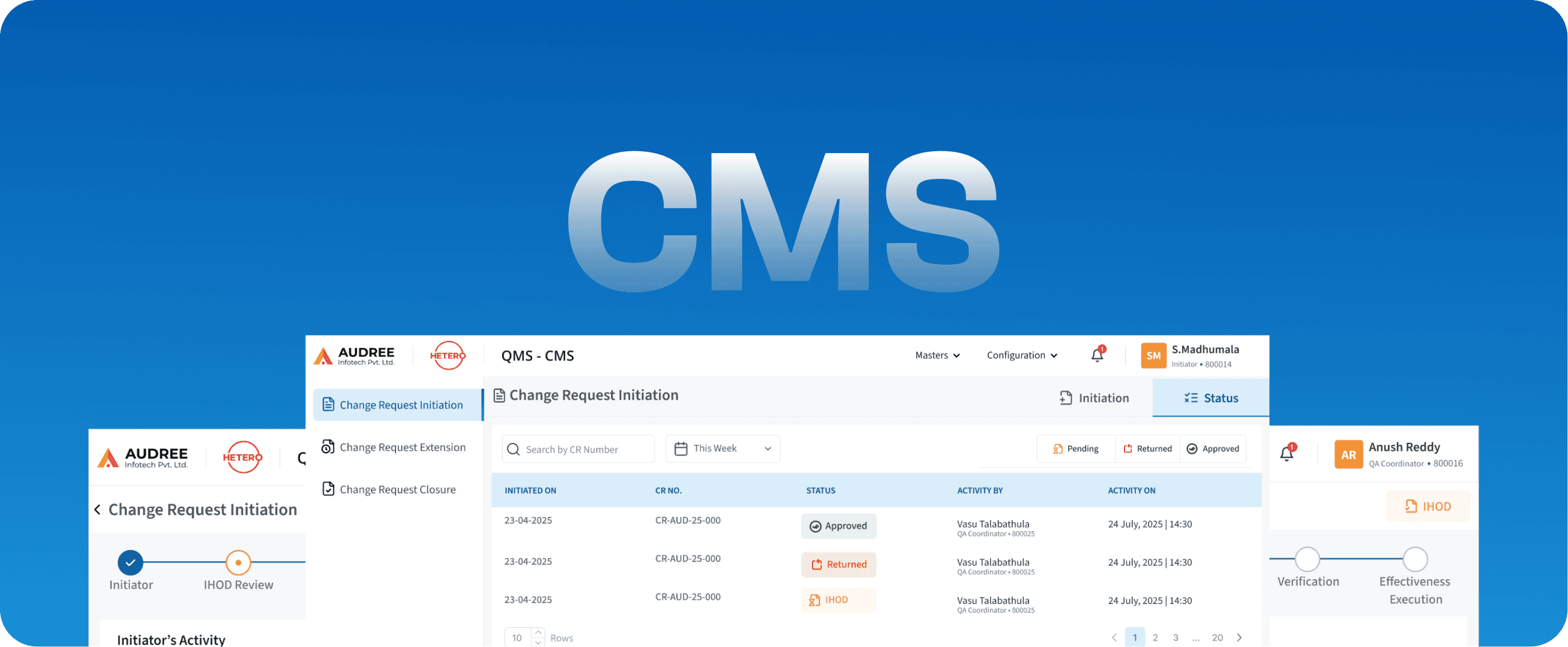

CMS

Change Management System

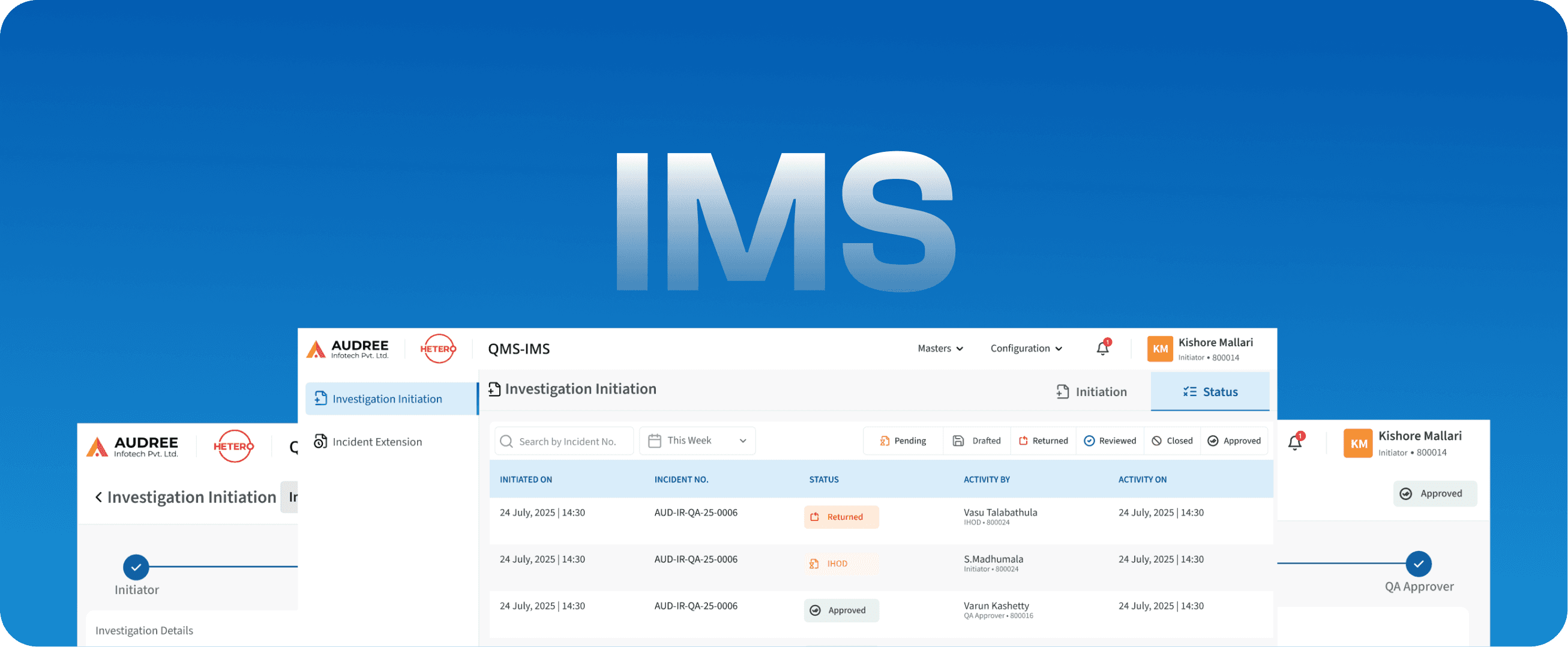

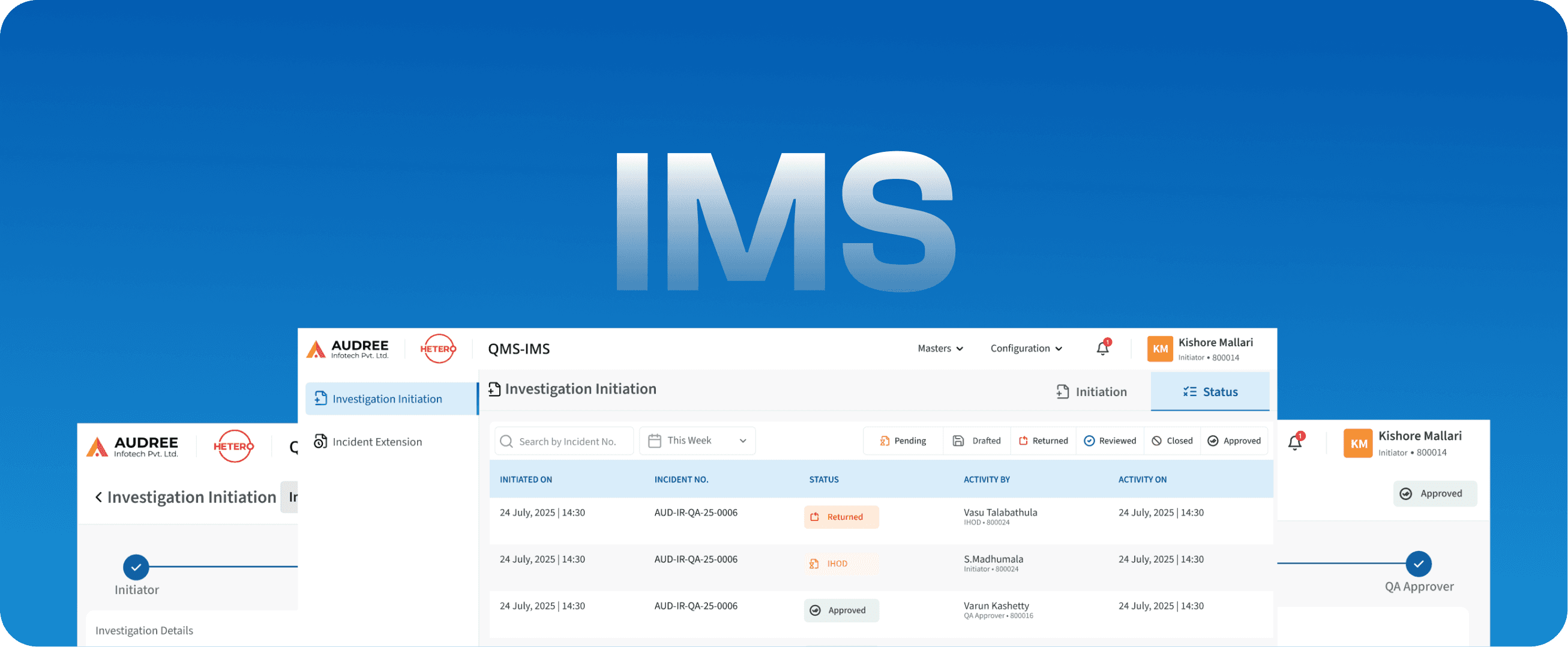

IMS

Incident Management System

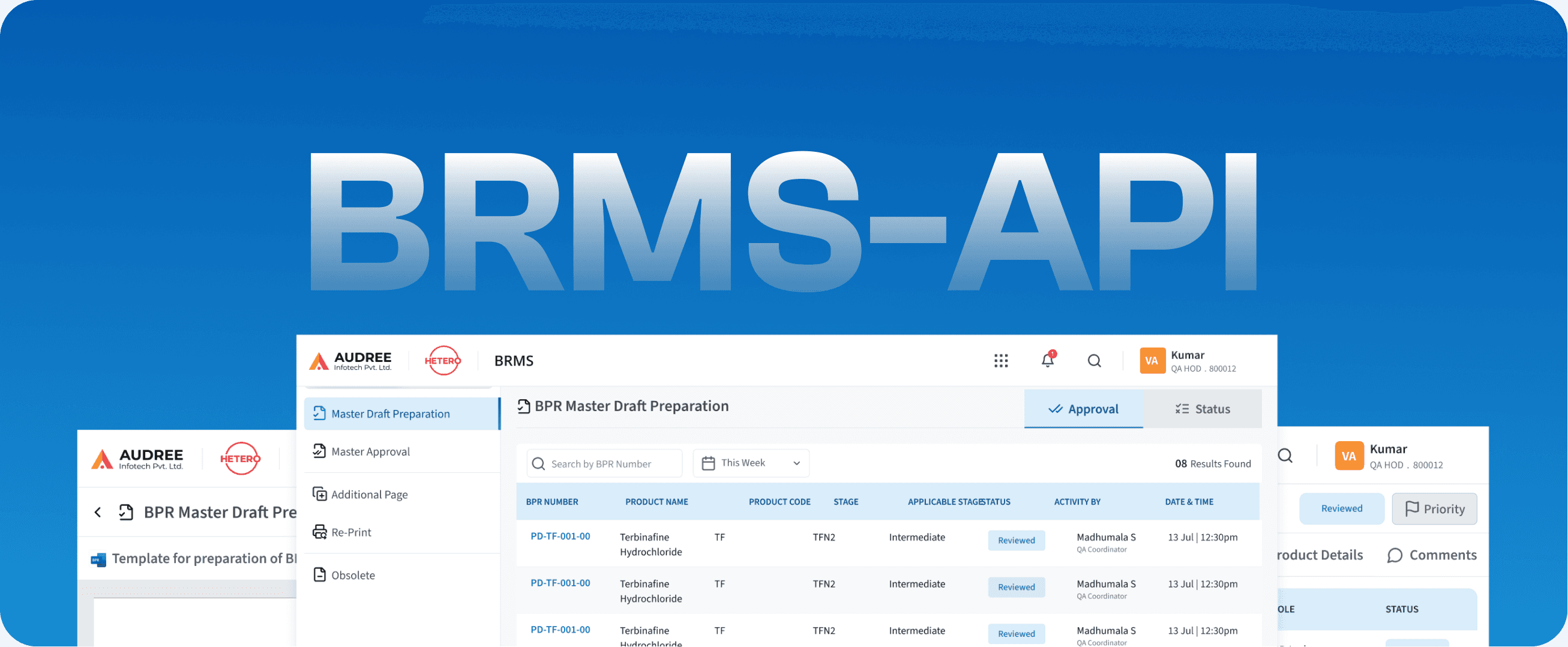

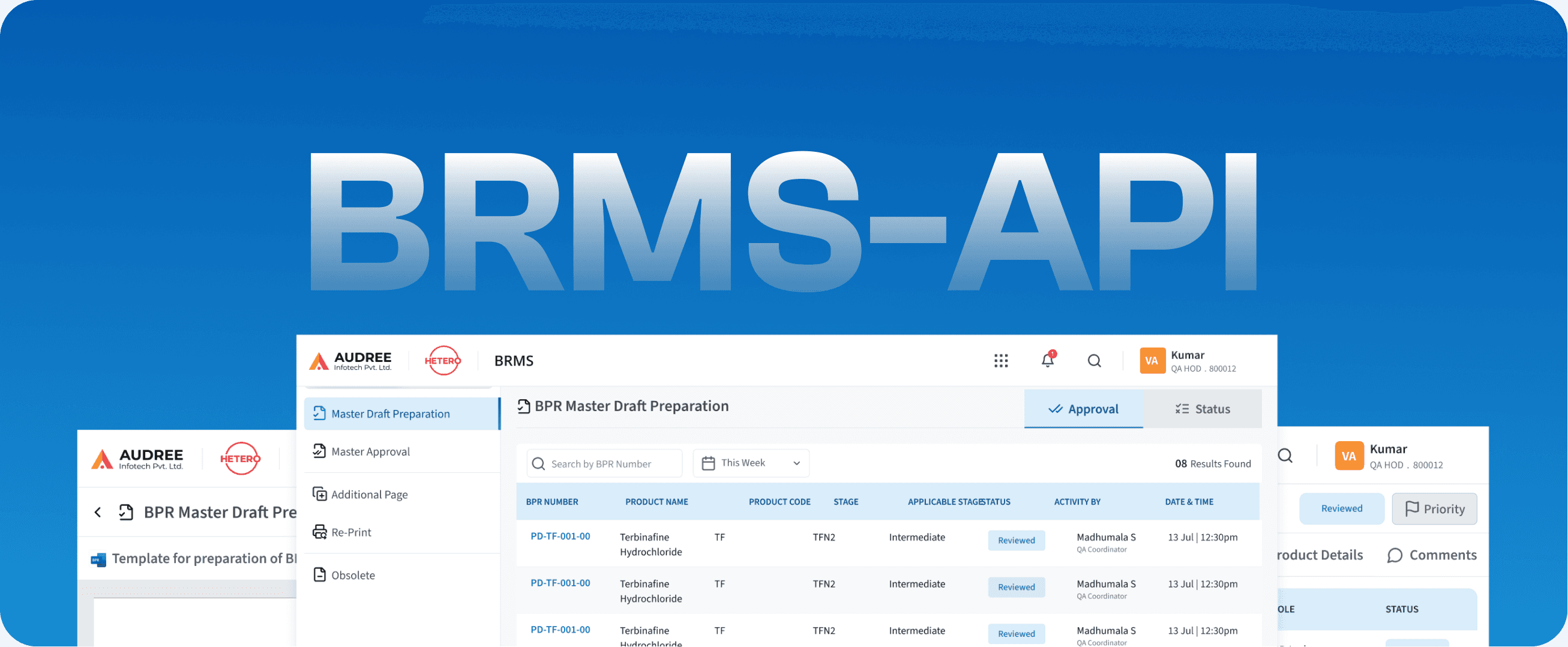

BRMS-API

Batch Record- Active Pharmaceutical Ingredient

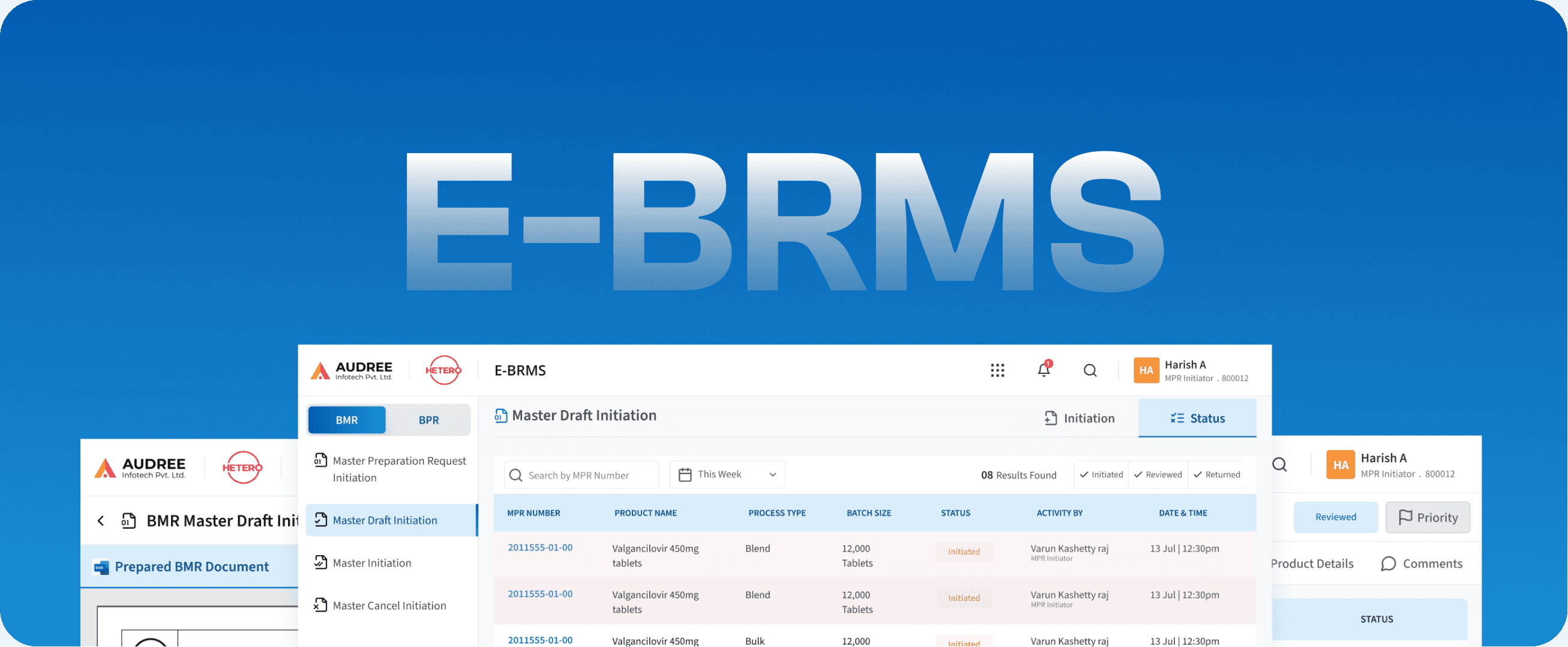

E-BRMS

Batch Record Management System

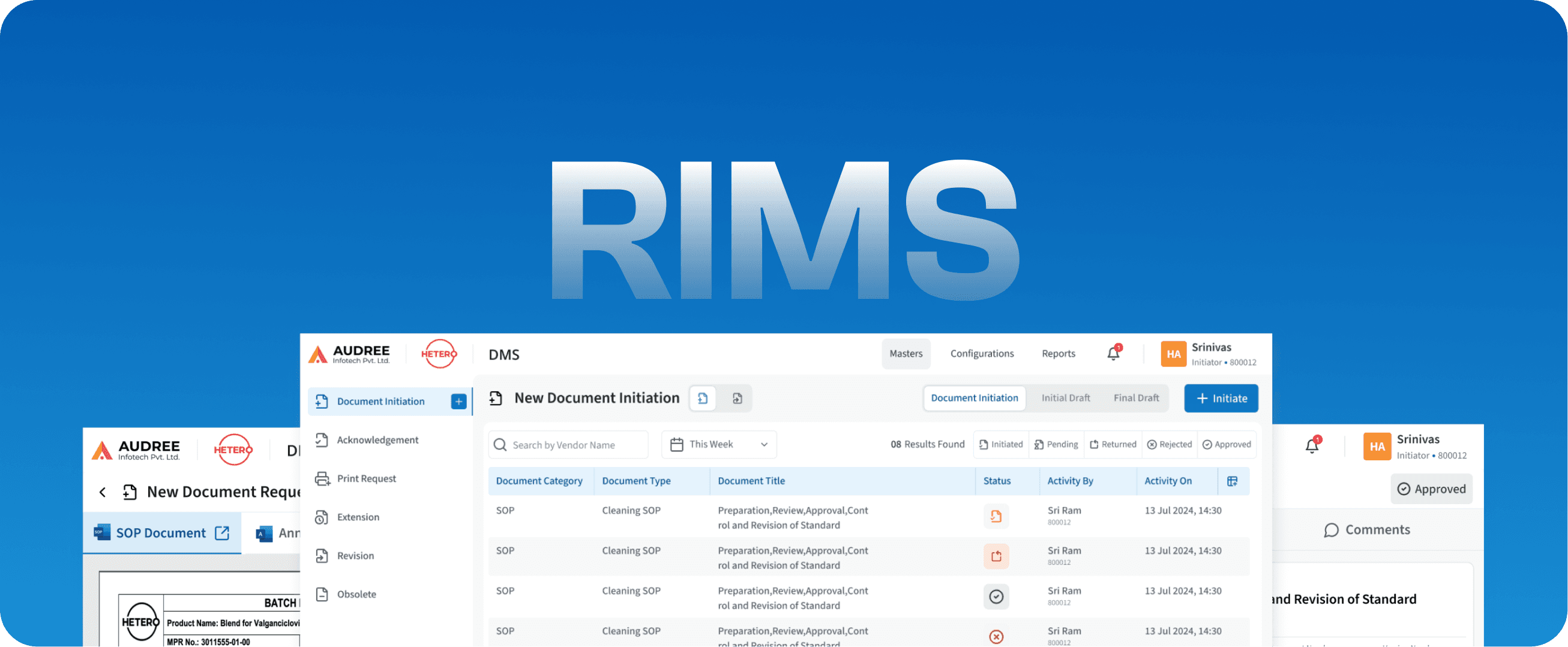

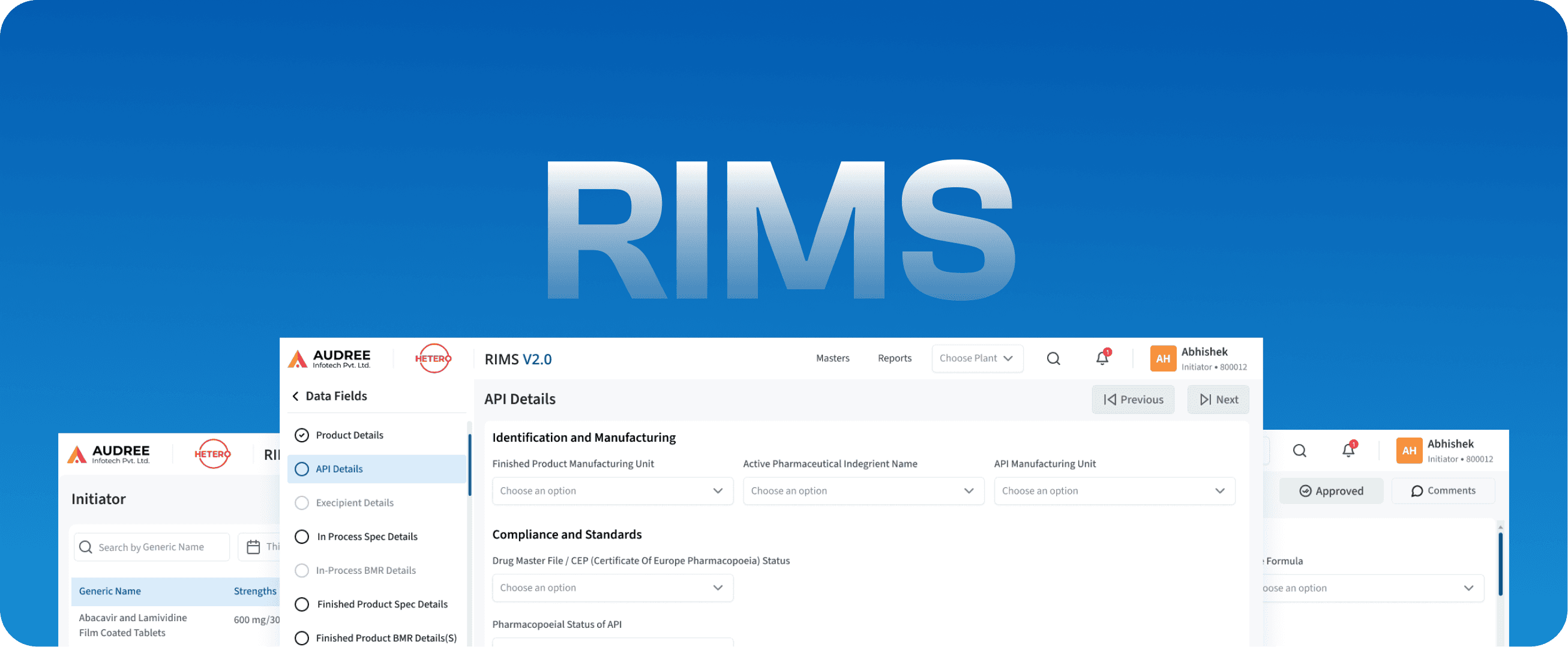

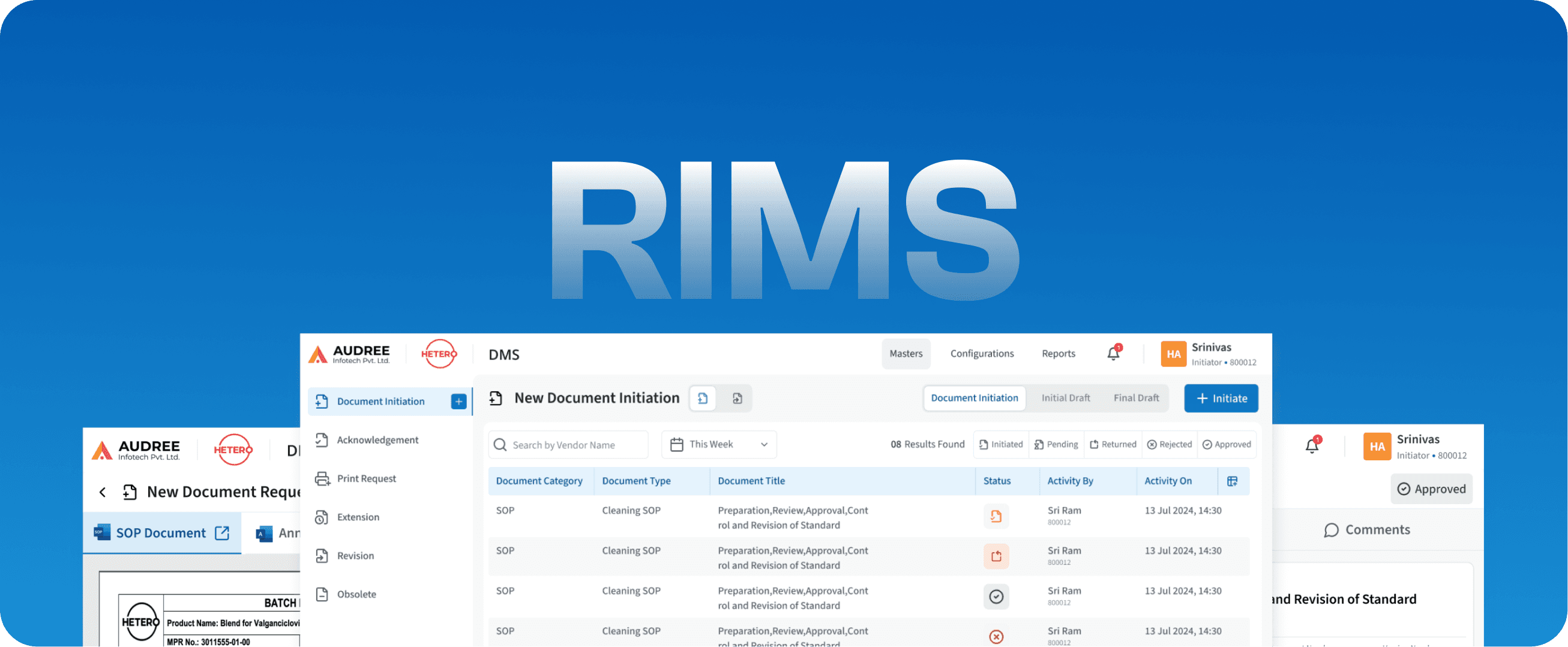

RIMS

Regulatory Information Management System

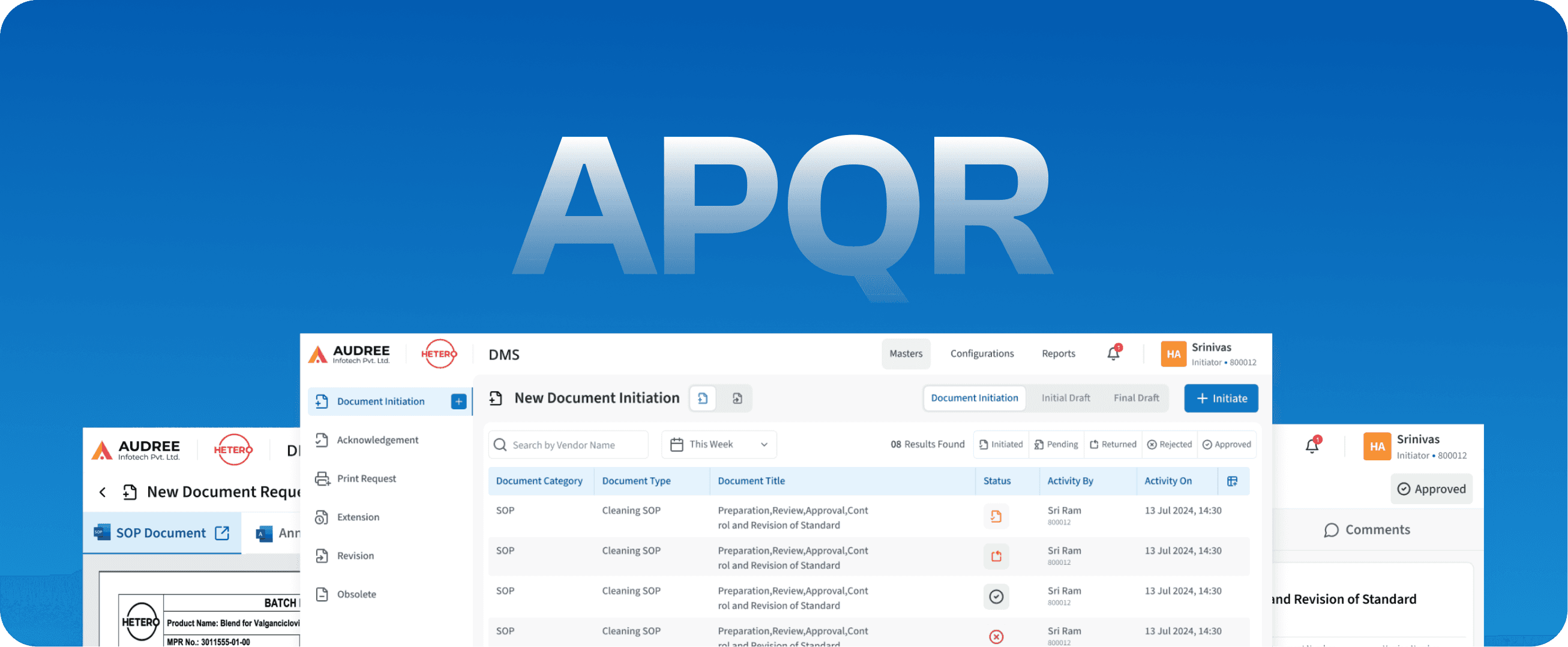

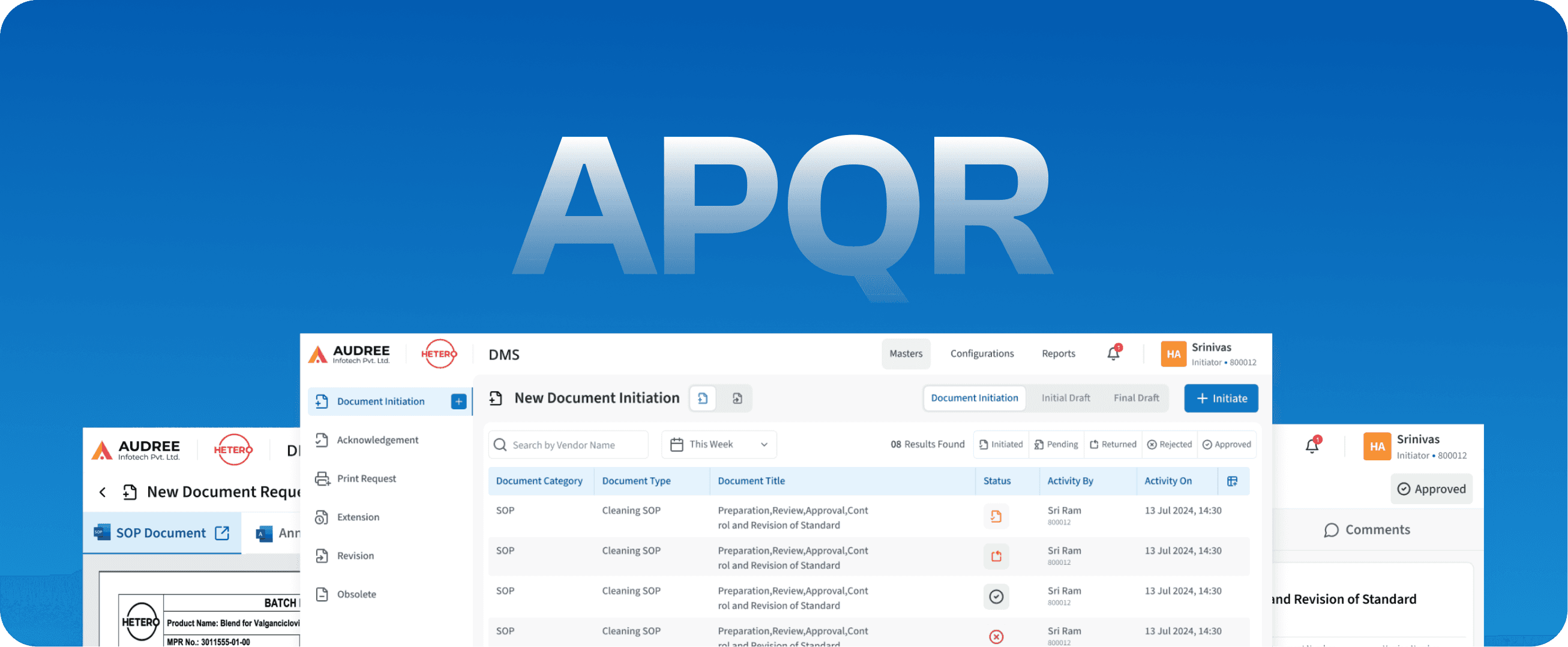

APQR

Annual Product Quality Review

RCAI

Root Cause Analysis with Intelligence

LMS

Learning Management System

LIMS

Laboratory Information Management System

S & OP

Sales & Operations Planning

E-BMR

Batch Manufacturing Recall

RIMS

Regulatory Information Management Systems

IMS

Incident Management System

BRMS-API

Batch Record- Active Pharmaceutical Ingredient

E-BRMS

Batch Record Management System

APQR

Annual Product Quality Review

RIMS

Regulatory Information Management System

WMPS

Warehouse Management System

DMS

Document Management System

CMS

Change Management System

OOS

Out Of Specification

LIR-AER

Laboratory Information Record

Vendor Portal

Vendor Management System

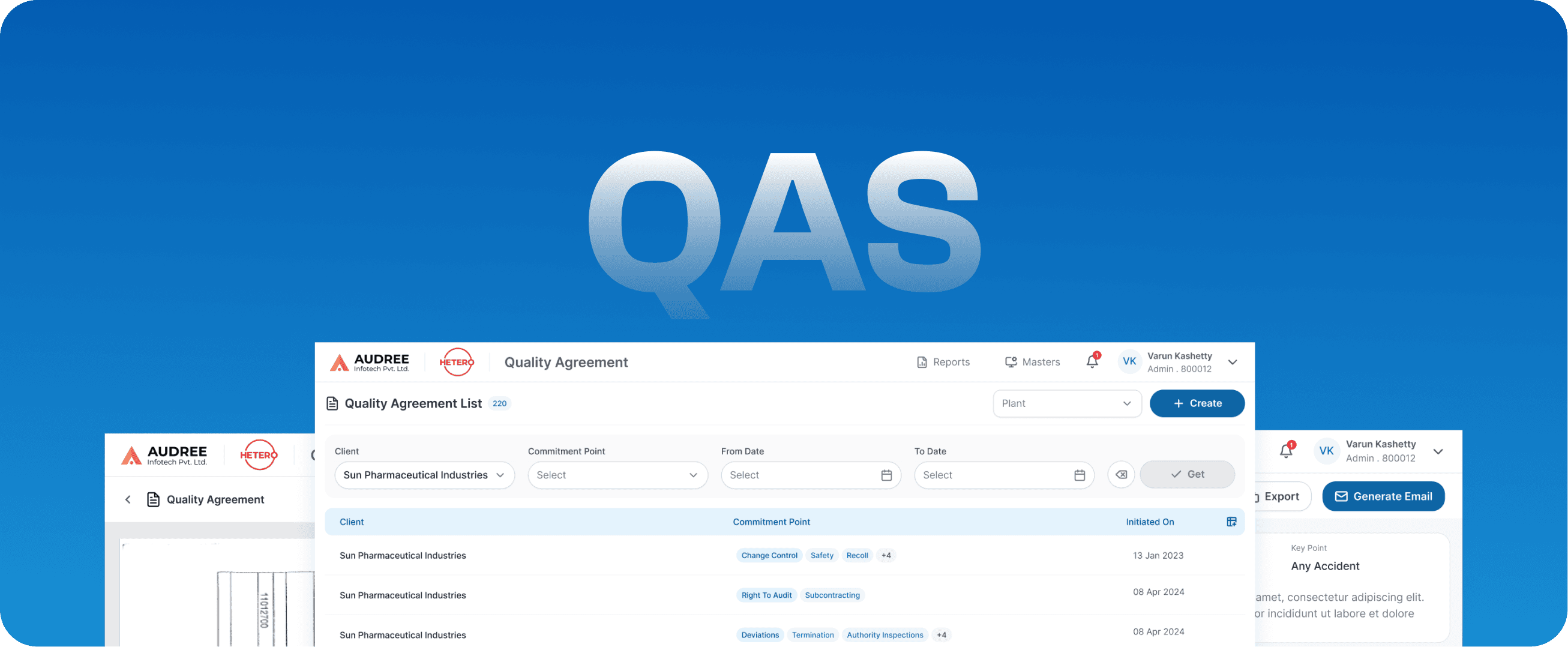

QAS

Quality Agreement System

CAPA

Corrective And Preventive Actions